Progress of Microalgal Biodiesel Research in Pakistan

*Corresponding Author(s):

Yue ShiCollege Of Power And Energy Engineering, Harbin Engineering University, Harbin, China

Tel:+86-185-4581-2660,

Fax:+86-451-82519305

Email:asad.nednust@gmail.com, shiyue@hrbeu.edu.cn

Abstract

Keywords

INTRODUCTION

Extensive utilization of fossil fuels not only decreases the sources of their production while also cause environmental pollution, energy crisis and global climatic change. Therefore, scientists and researchers all around the globe are focusing their attention to finding alternative, renewable & sustainable energy fuel sources and developing better energy conversion techniques [5]. Biofuels are sustainable energy resource and they have emerged as an encouraging substitution to conventional energy source [6,7]. They are readily available worldwide while also being renewable and can be acquired from prevailing biological resources [8].

Biofuels cover biodiesel, bioethanol and biogas. Biodiesel is manufactured from multiple feed stock including animal fat, vegetable oils and waste cooking oil. Biodiesel is typically produced through the reaction of vegetable oil or animal fat with methanol or ethanol in the presence of a catalyst to yield glycerin and biodiesel (chemically called methyl or ethyl esters). Biodiesel can be used in neat form, or blended with petroleum diesel for use in diesel engines. As far as operation of diesel engine is concerned, the physical and chemical properties of biodiesel are similar to petroleum based diesel fuel. The comparison of similar properties of biodiesel and petroleum diesel fuels is shown in table 1, biodiesel can also be blended in any ratio with petroleum diesel fuel.

|

Fuel Characteristics |

Diesel |

Biodiesel |

|

Kinematic viscosity at 35°C (mm2/s) |

812 |

865 |

|

Density at 35°C (kg/m3) |

2.90 |

4.9 |

|

Heating value (MJ/kg) |

42.6 |

37.3 |

|

Cetane number |

46 |

> 49 |

|

Mass ratio |

|

|

|

Mass content C |

0.860 |

0.7750 |

|

Mass content H |

0.136 |

0.1210 |

|

Mass content S |

0.003 |

0.0001 |

|

Mass content O |

---- |

0.1040 |

|

Stoichiometric ratio (air/fuel) |

14.5 |

12.4 |

The stock of biodiesel feed stocks is limited which hampers the exploration of biodiesel production. Feed stocks can be categorized in three generations for biodiesel production. First generation comprises of oil seeds and food crops such as soyabeans, rapeseed, sunflower and palm oil. These feed stocks were primarily used for biofuel production [10]. The second generation feed stock includes whole plant tissues, including energy crops such as Jetropha sp., Madhuca longifolia, salmon oil, tobacco seed, jojoba oil and sea mango [11]. Third generation biodiesel feed stock is microorganisms and widevariety of these can be employed for this purpose. Microalgae is the most prominent and promising third generation feedstock for biodiesel production [12]. High oil content, the cheapest source and rapid biomass production are the traits which reassure that microalgae is recognized as a potentially good source of biodiesel production [13-15].

In comparison to the oil production from crops, oil production growth rates from microalgae are much greater as shown in table 2 [14]. Algal biomass can be produced in marginal land, compact bioreactors and saline water bodies as compared to oil producing crops [16]. Oil content of different microalgae reported in literature is shown in table 3.

|

S.No |

Crop |

Oil Production (L/ha) |

|

1 |

Corn |

172 |

|

2 |

Soybean |

446 |

|

3 |

Canola |

1190 |

|

4 |

Jatropha |

1892 |

|

5 |

Cocunut |

2689 |

|

6 |

Oil Palm |

5950 |

|

7 |

Microalgae (70% oil (by wt) in biomass) |

136,900 |

|

8 |

Microalgae (30% oil (by wt) in biomass) |

58,700 |

|

S.No |

Microalgae |

Oil Content (% dry weight) |

|

1 |

Botryococcus braunii |

25-75 |

|

2 |

Chlorella sp. |

28-32 |

|

3 |

Crypthecodinium cohnii |

20 |

|

4 |

Cylindrotheca sp. |

16-37 |

|

5 |

Dunaliella primolecta |

23 |

|

6 |

Isochrysis sp. |

25-33 |

|

7 |

Monallanthus salina |

>20 |

|

8 |

Nannochloris sp. |

20-35 |

|

9 |

Nannochloropsis sp. |

31-68 |

|

10 |

Neochloris oleoabundans |

35-54 |

|

11 |

Nitzschia sp. |

45-47 |

|

12 |

Phaeodactylum tricornutum |

20-30 |

|

13 |

Schizochytrium sp. |

50-77 |

|

14 |

Tetraselmis sueica |

15-23 |

The objective of this study is to provide state-of-the-art information on microalgal biodiesel research in Pakistan and also to identify the potential opportunity of the feedstocks for biodiesel production.

BIODIESEL PRODUCTION PATHWAY FROM MICROALGAL BIOMASS

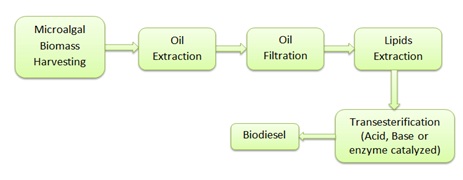

Figure 1: Microalgal biodiesl production pathway.

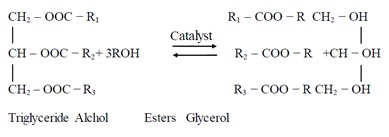

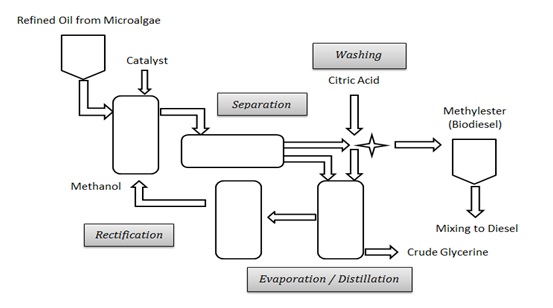

Figure 1: Microalgal biodiesl production pathway.The harvesting consists of recovery of microalgal biomass from culture broth. Harvesting is a costly process and it contributes to 20-30% of the total production cost of biomass [18]. Harvesting can be done by flocculation, sedimentation, filtration and centrifugation. Harvesting is followed by drying to remove water untill dry weight is achieved. Extraction of lipids and fatty acids are required to produced biodiesel. Solvent extraction is commonly applied to extract lipids and fatty acids from microalgal biomass, as it is quick and efficient method. Hexane, ethanol (96%), or hexane-ethanol (96%) mixture are usually used for this purpose [18]. Microalgal lipids undergo transesterification as per the chemical reaction shown in figure 2, in which oil is mixed with alcohol to produce ester and glycerol while ethanol is reclaimed. Schematic diagram of esterification process of microalgal oil to biodiesel is shown in figure 3. Table 4 summarizes production processes of biodiesel from microalgae.

Figure 2: Chemistry of esterification.

Figure 2: Chemistry of esterification. Figure 3: Schematic of esterification process of microalagl oil to biodiesel.

Figure 3: Schematic of esterification process of microalagl oil to biodiesel.|

Process |

Technique |

Microalgae |

Result |

Reference |

|

Cultivation |

Raceway ponds |

Chlorella vulgaris |

585 T of lipid extracted algae per day |

[19] |

|

Photobioreactor |

Cyclotella sp. |

51% lipids productivity increase in 72 h |

[20] |

|

|

Photobioreactor |

Chlorella sp.

|

7% increase in surface productivity

|

[21] |

|

|

Porphyridium cruentum |

37.26% increase in biomass productivity |

|||

|

Batch mode cultivation |

Chlorella vulgaris Scenedesmusobliquus Ourococcusmultisporus |

Lipid productivity(0.164 g-lipids g-cell−1day−1) |

[22] |

|

|

Harvesting |

Flocculation |

Chlorellaminutissima |

60% recovery efficiency of biomass |

[23] |

|

Chlorella vulgaris |

Concentrates up to 357 times that of theoriginal dry weight |

[24] |

||

|

Chlorella sp. |

100% harvesting efficiency |

[25] |

||

|

Chlorella sp. |

> 91% harvesting efficiency |

[26] |

||

|

Gravity sedimentation |

Chlorella vulgaris |

60% of biomass recovery |

[27] |

|

|

Lipid Extraction |

Wet lipid extraction |

Chlorella Scenedesmus sp. |

79% extraction of transesterifiable lipids |

[27] |

Table 4: Summary of production processes of biodiesel from microalgae.

PROGRESS OF BIODIESEL RESEARCH IN PAKISTAN

The first attempt to produce biodiesel from algal biomass in Pakistan was carried out by Khola et al., [29]. He studied Cladophora sp. The study highlighted the biomass after oil extraction, pH and quantitative properties of obtained biodiesel. Khola compared the quality of biodiesel with Oedogonium sp. and Spirogyra sp. [31]. Obtained results indicated that Cladophora sp. produces more quantity of biodiesel as compared to Oedogonium sp. and Spirogyra sp. Ahmad et al., [31] studied the waste water nutrition for growth of microalgae and its use for biodiesel production. He used mixed algae culture composed of Microspora sp., Diatoms, Lyngbya sp., Caldophora sp., Spirogyra sp. and Rhizoclonium sp. Results showed that the growth of mixed algae culture was promising and the biodiesel produced was in accordance with the ASTM standards.

Musharraf et al., [16] performed the Gas Chromatography-Mass Spectrometry (GC-MS/MS) analysis of Fatty Acid Methyl Esters (FAMEs) and biodiesel production study for six microalgae strains (Scenedesmus quadricauda, Scenedesmus acuminatus, Nannochloropsis sp., Anabaena sp., Chlorella sp. and Oscillatoria sp.) collected from fresh and marine water resources located in southern region of Pakistan. Results proposed that microalgae found in southern Pakistan has a potentially active growth rate and can be used for biodiesel production. Ahmad et al., [32] performed a study to find out the biodiesel efficiency of Chlorella vulgaris, Rhizoclonium hieroglyphicum and mixed culture algae by transesterification process. It was suggested by the study that raw municipal waste water can be used for the growth of algal species. The biodiesel obtained was compared with ASTM standards.

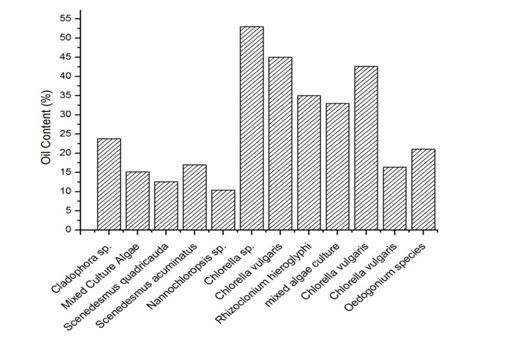

Ahmad et al., [33] studied the treatment of municipal waste water and biodiesel production by employing Chlorella vulgaris. Results showed that Chlorella vulgaris produced biodiesel of good quality which conformed to the ASTM standards. Further, the study indicated that the treated waste water can be used for irrigation purpose as it has BOD and COD within the limits of national environmental quality standards. Fatima et al., [34] used two freshwater algae species (Chlorella vulgaris and Oedogoniumspecies) for biodiesel production. The Chlorella species produced 6.26 g oil from 38.23 g of dry weight and the Oedogonium species produced 8.07 g of oil from 38.23 g of dried weight. Alam et al., [35] inspected 17 species from fresh water sources of Khyber Pakhtunkhwa. Chroococcus turgidus, Sirogonium sticticum, Uronema elongatum and Temnogyra reflexa produced the highest amounts of oil amongst all others. Oil percentages of different microalgae species investigated in Pakistan are presented in table 5.In Pakistan, there exists vast potential to produce biodiesel from mircoalgal biomass. It has been observed from this study and highlighted in figure 4 that Chlorella sp. (fresh water algae) produced the highest amount of oil content percentage followed by Chlorella vulgaris which grows in waste water. Rhizoclonium hieroglyphicum and mixed algae culture also produced considerable amount of oil content for biodiesel production.

Figure 4: Oil content (%) of microalgal species existing in Pakistan.

Figure 4: Oil content (%) of microalgal species existing in Pakistan.|

Algae Type |

Location |

Habitat |

Oil Percent (%) |

Reference |

|

Cladophora sp. |

Aquatic ponds of GC University Botanic Garden |

Fresh Water |

23.8 |

[29] |

|

Mixed culture algae: · Microspora sp. · Diatoms · Lyngbya sp · Caldophora sp. · Spirogyra sp. · Rhizoclonium sp. |

Aquatic ponds of GC University Botanic Garden |

Waste Water |

15.13 |

[31] |

|

Scenedesmus quadricauda |

Southern Pakistan |

Fresh Water |

12.6 |

[16] |

|

Scenedesmus acuminatus |

Fresh Water |

17 |

||

|

Nannochloropsis sp. |

Marine |

10.4 |

||

|

Anabaena sp. |

Fresh Water |

2.98 |

||

|

Chlorella sp. |

Fresh Water |

53 |

||

|

Oscillatoria sp. |

Marine |

3.69 |

||

|

Chlorella vulgaris |

Fish forms and laboratory of Punjab Fisheries Department, Lahore Pakistan. |

Waste Water |

45 |

[32] |

|

Rhizoclonium hieroglyphicum |

35 |

|||

|

Mixed algae culture |

33 |

|||

|

Chlorella vulgaris |

Fish forms of Department of Fisheries near Manawa police station Lahore, Pakistan |

Waste Water |

42.66 |

[33] |

|

Chlorella vulgaris |

Freshwater sources like tube wells, irrigation channels, aquatic ponds, and fish ponds in Faisalabad |

Fresh Water |

16.37 |

[34] |

|

Oedogonium species |

21.1 |

|||

|

S. sticticum |

Natural springs of Landikotal, Swabi and Swat, water logging of Shabqadar and Mardan, and water tanks of Malakand districts of Khyber Pakhtunkhwa |

Fresh Water

|

7.5 |

[35] |

|

U. elongatum |

7 |

|||

|

C. tergidus |

8.5 |

|||

|

T. reflexa |

7 |

|||

|

C. glomerata |

2 |

|||

|

S. dictyospora |

3.2 |

|||

|

E. procera |

3 |

|||

|

H. klibsii |

5 |

|||

|

H. reticulatum |

5.5 |

|||

|

M. abnarmaus |

4 |

|||

|

O. angustissimum |

6.3 |

|||

|

R. crassiplitum |

6 |

|||

|

P. oedogonia |

5 |

|||

|

B. gigantea |

2.5 |

|||

|

C. cryptica |

3.3 |

|||

|

T. cylindrica |

4 |

|||

|

O. minima |

4.5 |

Table 5: Oil percent of different microalgae species investigated in Pakistan.

INVERSTMENT OPPORTUNITY IN BIODIESEL

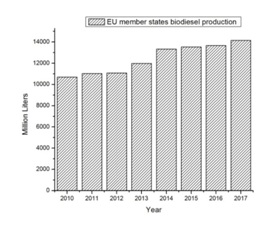

Figure 5: Biodiesel production of EU member states [36].

Figure 5: Biodiesel production of EU member states [36]. Figure 6: Leading biodiesel producers worldwide in 2016 [37].

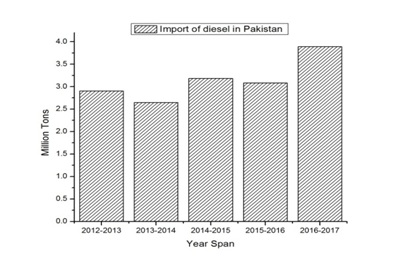

Figure 6: Leading biodiesel producers worldwide in 2016 [37].Pakistan has been importing diesel fuel every year and despite the fact that local manufacturing of diesel reduced the volume of import during the year 2013-2014, the import of diesel has significantly risen to 3.54 million tons for the year 2016-2017 as shown in figure 7.

The production cost of microalgal biodiesel depends on various factor including the harvesting cost, filtration cost, extraction cost and esterification system cost. At the moment, production cost of microalgae biodiesel is considered far more costly when one compares it to petroleum diesel fuels. Chisti [14] calculated the production cost of microalgal oil manufacturing from a photobioreactor for an annual production capacity of 10,000 tons per year. If one assumes the oil content of around 30%, the production cost by the author comes $2.80/L ($10.50/gallon). The costs of esterification process, distribution, taxes and marketing cost for biodiesel are not included in this estimation. Similarly, the petroleum diesel price was estimated to be $2 to $3 per gallon. Following equationis used by Chisti [14] for the estimation of the cost of algal oil where it can be a spirited alternative for petroleum diesel.

Calgal oil = 25.9 ×10-3 Cpetroleum

Where, Calgal oil constitutes the price of micro algal oil in $/gallon and Cpetroleum is the price of crude oil in $/barrel.

CONCLUSION AND FUTURE PROSPECTS

ACKNOWLEDGMENT

REFERENCES

- Tahir S, Rafique M, Alaamer A (2010) Biomass fuel burning and its implications: Deforestation and greenhouse gases emissions in Pakistan. Environmental Pollution 158: 2490-2495.

- CIA World Factbook (2014) Petroleum Comsumption. CIA World Factbook, USA.

- Saleh N, Mushtaq K, Zaidi AA, Abbaso?lu S, Ahmed SF (2016) Design and performance analysis of a solar powered hybrid rickshaw for commercial use in Pakistan. Journal of Environmental Science and Technology 9: 472-480.

- Khan MI (2016) Pakistan energy sector and its prospects for business.

- Mushtaq K, Zaidi AA, Askari SJ (2016) Design and performance analysis of floating dome type portable biogas plant for domestic use in Pakistan. Biotechnology 14: 21-25.

- Gressel J (2008) Transgenics are imperative for biofuel crops. Plant Science 174: 246-263.

- Shah SH, Ahmed Raja I, Qaisar Mahmood, Arshid Pervez (2016) Improvement in lipids extraction processes for biodiesel production from wet microalgal pellets grown on diammonium phosphate and sodium bicarbonate combinations. Bioresour Technol 214: 199-209.

- Ziolkowska JR (2014) Optimizing biofuels production in an uncertain decision environment: Conventional vs. advanced technologies. Applied Energy 114: 366-376.

- Filipovic I, Pikula B, Bibic D, Kepnik G (2013) Impact of physical properties of diesel and biodiesel mixture on characteristics of fuel spraying. Goriva I Maz 52: 16-28.

- Demirbas MF (2011) Biofuels from algae for sustainable development. Applied Energy 88: 3473-3480.

- Carriquiry MA, Xiaodong Du, Timilsina GR (2011) Second generation biofuels: Economics and policies. Energy Policy 39: 4222-4234.

- Beetul K, Sadally SB, Taleb Hossenkhan N, Bhagooli R, Puchooa D (2014) An investigation of biodiesel production from microalgae found in Mauritian waters. Biofuel Research Jornal 2: 58-64.

- Wen Z, Johnson MB (2009) Microalgae as a feedstock for biofuel production. Virginia Cooperative Extension, Petersburg,Virginia, USA.

- Chisti Y (2007) Biodiesel from microalgae. Biotechnology Advances 25: 294-306.

- Petkov G, Ivanova A, Iliev I, Vaseva I (2012) A critical look at the microalgae biodiesel. Eur J Lipid Sci Technol 114: 103-111.

- Musharraf SG, Ahmed MA, Zehra N, Kabir N, Choudhary MI, et al. (2012) Biodiesel production from microalgal isolates of southern Pakistan and quantification of FAMEs by GC-MS/MS analysis. Chem Cent J 149.

- Mondal M, Goswami S, Ghosh A, Oinam G, Tiwari ON, et al. (2017) Production of biodiesel from microalgae through biological carbon capture: a review. 3 Biotech 7: 99.

- Mata TM, Martins AA, Caetano NS (2010) Microalgae for biodiesel production and other applications: A review. Renewable and Sustainable Energy Reviews 14: 217-232.

- Rogers JN, Rosenberg JN, Guzman BJ, Oh VH, Mimbela LE, et al. (2014) A critical analysis of paddlewheel-driven raceway ponds for algal biofuel production at commercial scales. Algal Research 4: 76-88.

- Jeffryes C, Rosenberger J, Rorrer GL (2013) Fed-batch cultivation and bioprocess modeling of Cyclotella for enhanced fatty acid production by controlled silicon limitation. Algal Research 2: 16-27.

- Zhang Q, Wu X, Xue S, Liang K, Cong W (2013) Study of hydrodynamic characteristics in tubular photobioreactors. Bioprocess Biosyst Eng 36: 143-150.

- Min-Kyu Ji, Abou-Shanab RAI, Sang-Hun Kim, El-Sayed Salama, Sang-Hun Lee, et al. (2013) Cultivation of microalgae species in tertiary municipal wastewater supplemented with CO2 for nutrient removal and biomass production. Ecological Engineering 58: 142-148.

- Papazi A, Makridis P, Divanach P (2010) Harvesting Chlorella minutissima using cell coagulants. Journal of Applied Phycology 22: 349-355.

- Ras M, Lardon L, Bruno S, Bernet N, Steyer JP (2011) Experimental study on a coupled process of production and anaerobic digestion of Chlorella vulgaris. Bioresour Technol 102: 200-206.

- Lee YC, Oh SY, Lee HU, Kim B, Lee SY, et al. (2014) Aminoclay-induced humic acid flocculation for efficient harvesting of oleaginous Chlorella sp. Bioresour. Technol 153: 365-369.

- Udom I, Zaribaf BH, Halfhide T, Gillie B, Dalrymple O, et al. (2013) Harvesting microalgae grown on wastewater. Bioresour Technol 139: 101-106.

- Pragya N, Pandey KK, Sahoo PK (2013) A review on harvesting, oil extraction and biofuels production technologies from microalgae. Renewable and Sustainable Energy Reviews 24: 159-171.

- Guiry MD (2012) How many species of algae are there? J Phyco 48: 1057-1063.

- Khola G, Ghazala B (2012) Biodiesel production from algae. Pak J Bot 44: 379-381.

- Hossain AS, Salleh A (2008) Biodiesel fuel production from algae as renewable energy. American Journal of Biochemistry and Biotechnology 4: 250-254.

- Ahmad F, Khan AU, Yasar A (2012) Uptake of nutrients from municipal wastewater and biodiesel production by mixed algae culture.. Pakistan Journal of Nutrition 11: 648-652.

- Ahmad F, Khan AU, Yasar A (2013) The potential of chlorella vulgaris for wastewater treatment and biodiesel production. Pak J Bot 45: 461-465.

- Ahmad F, Khan AU, Yasar A (2013) Transesterification of oil extracted from different species of algae for biodiesel production. African Journal of Environmental Science and Technology 7: 358-364.

- Fatima N, Mahmood MS, Hussain I, Siddique F, Hafeez S (2016) Transesterification of oil extracted from freshwater algae for biodiesel production. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects 38: 2306-2311.

- Alam A, Ullah S, Aftab S, Alam S, Khan Y, et al. (2017) Evaluation of Sirogonium sticticum, Uronema elongatum, Chroococcus turgidus and Temnogyra reflexa for biodiesel production in Pakistan. Biofuels 8: 391-399.

- Flach B, Lieberz S, Rondon M, Williams B, Wilson C (2016) EU Biofuels Annual 2016: USDA Foreign Agricultural Services, Global Agricultural Information Network, Washington DC, USA.

- The Statistics Portal-Statistics and Studies from more than 18,000 Sources (2016).

- Anonymous (2016) Import-Export. Islamabad: Oil Companies Advisory Council (OCAC).

Citation: Zaidi AA, Malik A, Mushtaq K, RuiZhe F, Shi Y (2018) Progress of Microalgal Biodiesel Research in Pakistan . J Plant Sci Curr Res 2: 004

Copyright: © 2018 Adil Malik, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.