Analysis of Sowing Quality of Sugar Beet Seeds Before and After Sowing by Pneumatic and Mechanical Seed Meter

*Corresponding Author(s):

Kateryna VasylkovskaCentral Ukrainian National Technical University (CUNTU), Kropyvnytskyi 25030, Ukraine

Email:vasilkovskav@ukr.net

Abstract

A new pneumatic and mechanical seed meter with a peripheral arrangement of cells and passive appliance for removing excess seeds by centrifugal method is suggested. The method allows increasing circular velocity of the sowing disc and matching its velocity with the translational velocity of the seed drill. A working hypothesis is proposed in which the capture of seeds and their transportation to the discharge zone occurs with the help of a shoulder, which securely holds the seeds in the cell. However, the design of the seed disc with the blade could damage the seed during operation of the seed drill. During the operation of the sowing machine, a window for photo and video shooting was made in the rear wall of the housing for control. Thus, it was possible to make sure that the seed rotates when moving from capture to discharge. And also whether the design of the sowing disc poses a threat to the viability of sugar beet seeds during sowing. In order to check the sowing properties of sugar beet seeds before and after sowing, the proposed seed meter determined the energy of seed germination, similarity and viability. The obtained results proved that the mechanical interaction of the structural elements of the seed meter does not affect the sowing quality of sugar beet seeds.

Keywords

Pneumatic & Mechanical Seed Meter, Sowing, Sugar Beet Seeds, Germination Energy, Seeds Viability

Introduction

World sugar production is about 200 million tons, about 70% of which is made from sugar cane and 30% from sugar beets. Despite global trends to reduce sugar consumption and sugar beet cultivation, Ukraine is in the top ten producers of root crops and sugar [1, 2].

Sugar beets productivity is directly proportional to the mass of roots and their sugar content. To a large extent, the productivity of root crops and their sugar content depend on a balanced nutrition of sugar beets throughout the growing season. Thus, precision sowing of seeds is a primary condition for obtaining evenly spaced plants with sufficient nutrition and development. The key to obtaining even sprouts, and later a good harvest is the uniformity of sowing seeds and, as a consequence, the uniformity of its location in the row [3, 4].

Modern pneumatic and mechanical precision seed meters, despite the long history of their creation and improvement, have a number of disadvantages, the main of which are: insufficient dosing capacity due to limited circular velocity of the seeding disc and the presence of random uncontrolled redistribution of intervals among seeds in the furrow during the movement of the seed drill at nominal speeds [2]. Elimination of these shortcomings is achieved by increasing the circular velocity of the seeding disc and aligning it with the translational velocity of the seed drill. This problem is technologically impossible to solve in the design of modern pneumatic and mechanical seed meters because it impairs the formation of single-seed flow at the initial stage of its formation [5].

Aligning the circular velocity of the seeding disk with the velocity of the seeding drill could not long be solved with the increase of crops productivity. The quality of operations is largely lost at the expense of the increased velocity of the seed drill [6].

The article aims at estimating the design of the new seed meter concerning its harmlessness to the sowing materials in use. In order to gain this aim, there was an objective set to study agronomic indicators of sugar beet seed quality before and after sowing.

Materials And Methods

In order to increase the efficiency of precision seeding, Central Ukrainian National Technical University developed a prototype section of a new pneumatic and mechanical seed meter for precision seeding of row crops [7, 8-10].

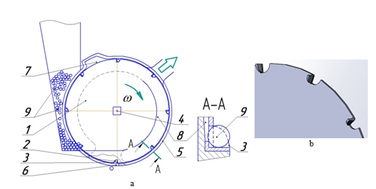

The main feature of the seed meter (Figure 1) is the use of a sowing disc with a peripheral location of cells, behind which on its inner surface there are blades for the forced capture of seeds by the disc in the operating chamber and its subsequent transportation to the discharge zone.

A passive appliance in the form of a cavity into which excess seeds fall and, separating from the disc, return to the filling zone was made. It is located in the upper part of the cylindrical surface of the housing. The appliance allows extracting excess seeds from the cells of the sowing disc.

In the lower part of the surface of the housing there is a seed hole which provides free fall of seeds to the furrow.

Figure 1: Suggested pneumatic and mechanical seed meter

Figure 1: Suggested pneumatic and mechanical seed meter

1 – seeding disc; 2 – cell; 3 – blade; 4 – driving shaft; 5 – housing; 6 – seeds exit; 7 – passive appliance for extracting excessive seeds; 8 – vacuum chamber; 9 – seeds;

a – drawing; b – three-dimensional model of the section of the sowing disc.

The proposed design of the pneumatic and mechanical disc seed meter eliminates its main shortcomings. It improves conditions and increases the reliability of the process of filling the seed disc cells. It also increases the efficiency of extracting excess seeds and the reliability of cell release in the sowing area. This provides a constant point of discharge of seeds from the sowing disc and equal trajectories of their flight to the furrow. Thus, it has a positive effect on the uniformity of distribution of intervals among seeds in the furrow.

Therefore, the proposed pneumatic and mechanical seed meter provides simultaneous increase in circular velocity of the sowing disc cells and significant reduce of pressure in the vacuum chamber, which will increase technological efficiency and productivity of the seed meter and reduce energy consumption of the sowing process. Thus, it is now possible to align the seed meter velocity with the circular velocity of the seeding disc cells (rate of rotation) without any productivity loss.

With increasing circular velocity of the sowing disc cells of the pneumatic and mechanical seed meter, seeds may be damaged by the elements of its construction. To confirm the absence of damage of the seeds by the elements of the seed meter, the sowing properties of sugar beet seeds were tested before and after sowing.

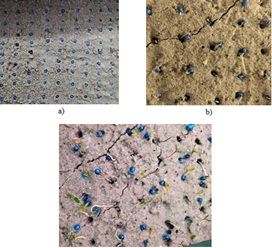

In the course of sowing with the help of the pneumatic and mechanical seed meter there was a transparent port made in the aft part of the housing in order to conduct photo and video registration of the research (figure 2). The analysis of the photos clearly shows that a seed in the cell does not rotate on its axis. The seed is captured in the sowing disc cells by the blades, makes a circular movement and gets to the discharge zone.

Figure 2: General view of the cell filling process

Figure 2: General view of the cell filling process

However, in order to ascertain that the suggested design of a pneumatic and mechanical seed meter with a peripheral arrangement of cells and specific cell shape with a blade for good seed capture in the seed chamber is appropriate, agronomic indicators of seed quality were studied.

So, we can disprove the hypothesis about mechanical damage to seeds caused by seed meter elements.

The most influential agronomic indicators of seed quality include seed germination energy and similarity [11].

The method of M. Firsova was used to determine similarity [12-14]. Selected seeds to determine similarity (four samples of 100 seeds) were laid for swelling in water with the temperature of 30°C for four hours. The water level was 1...2 cm above the seed surface. At the end of the swelling period, the seeds were removed and laid in moist sand. Before laying, the sand was leveled and compacted. The seeds were pressed into the sand along with its surface at the same distance from each other and covered with a layer of gauze and a layer of sand 0.5…1.0 cm thick. The upper layer of sand was also compacted. Germination of sugar beet seeds took place indoors at the temperature of 20°C for 30 hours, and then at 30°C for two days. To count the germinated seeds, a layer of sand was removed together with gauze.

Counting of germinated seeds was performed in two terms:

- first time in 4 days to determine the germination energy;

- second time in 10 days to determine similarity.

Germination energy was expressed as the percentage of the ratio of seeds that germinated over certain period to the total number.

Ungerminated seeds were considered those in which by the end of the period of determining the similarity, the stem consisted of one sprout, and the root did not develop definitively or developed sick, rotten.

At the end of the period of determining similarity and germination energy, the average of four samples was determined.

If the deviation was greater than the allowable, the percentage of germination energy and similarity was determined by three samples. And if deviations were found in two samples, the germination energy and similarity were determined by re-germination.

Viability was determined by V. Ivanov’s method [15,16]. Two samples of 100 seeds per sample were taken and soaked in water at room temperature (180… 230C) for 10-11 hours. The swollen seeds were partially dried on filter paper. Then with a sharp blade each seed was cut in half. Only one half of each seed was taken for dyeing and immediately placed into a glass of water, preventing it from drying out. After cutting the seeds, they were washed to remove the remnants of torn tissue from the cut surface. 5 ml of 0.1% solution of acid magenta was poured into the container with the seeds, gently shaken to remove the bubbles and the seeds were left for 10-15 minutes. The solution was then drained, and the seed halves were placed on filter paper and examined.

Viable seeds were all halves with unpainted embryo, non-viable were all seeds with partially or completely colored embryo. The percentage of viable seeds was set as the arithmetic mean of the two samples.

Two groups of containers with seed samples of sugar beet hybrids "before sowing" (not sown) and "after sowing" (those that were sown) were used for research (Figure 3).

Figure 3: General layout of the seeds: a – after sowing; b – on the 4th day; c – on the 10th day

Figure 3: General layout of the seeds: a – after sowing; b – on the 4th day; c – on the 10th day

CavosN-Type hybrid from Strube Ukraine GmbH was used for sowing. This is a monoecious diploid hybrid. This is an early production variety with high sugar content, productivity and high purity of juice. The hybrid is resistant to cercosporosis, rhizomania and rhizoctonia. Root crops are of the same shape and size, suitable for mechanized harvesting and easy digging out. The average productivity of root crops is 75.5 t/ha, sugar content is 19.04% [17].

Results & Discussion

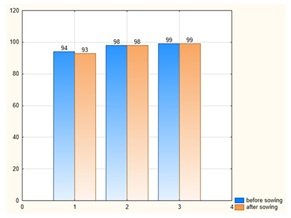

Experimental studies for sugar beet seeds before and after sowing showed the following results:

- for germination energy E1 = 94%, E2 = 93%;

- for similarity C1 = 98%, C2 = 98%.

This indicates that sowing sugar beet seeds by the pneumatic and mechanical seed meter with a peripheral arrangement of cells fully meets the requirements of DSTU 2153:2006 "Sugar beets" [4] (Figure 4).

Figure 4: Comparative diagram of germination energy, similarity and viability of sugar beet seeds

Figure 4: Comparative diagram of germination energy, similarity and viability of sugar beet seeds

Comparative analysis of sowing properties of sugar beet seeds before and after sowing showed that the developed pneumatic and mechanical seed meter performs technological process in accordance with agronomic requirements and the impact of its operation on germination energy and seed similarity is insignificant.

Experimental studies have shown that the average value of viability of sugar beet seeds before and after sowing with a pneumatic and mechanical seed meter with a peripheral location of cells is 99% (Figure 3).

Thus, the viability of sugar beet seeds before and after sowing does not differ. That is, the mechanical interaction of seed material with the structural elements of the seed meter does not have negative consequences and does not reduce the viability of seeds.

The results show that the sown material is suitable for further use in accordance with existing agronomic requirements [18].

Conclusions

Based on the experiments, the hypothesis of no damage to sugar beet seeds by structural elements of the pneumatic and mechanical seed meter with increasing circular velocity of the sowing disc cells proved to be true.

Experiments to verify the degree of damage to sugar beet seeds by operating parts of the pneumatic and mechanical seed meter found that the loss of germination energy after sowing is 1%, similarity is 0% and viability is 0%, which shows that sowing process of the proposed seed meter meets the requirements of DSTU 2153:2006 “Sugar Beets”.

Thus, it is now possible to align the seed meter velocity with the circular velocity of the seeding disc cells without any productivity loss. This means that the increased seed drill velocity with the suggested seed meter enables higher productivity, better quality technological process and given sowing accuracy.

References

- Angelovic M, Jablonický J, Tkác Z, Angelovic M (2020) Comparison of smoke emissions in different combustion engine fuels. Acta Technologica Agriculturae 23: 201-207.

- Liu Z, Zhang M, Han J, Zhuang Y, Lan Y, et al. (2021) Effect of seed filling and releasing angles on the performance of compound vacuum seed metering device. INMATEH – Agricultural Engineering 65: 153-162.

- An official website of the International Association for Official Statistics (IAOS) (2022) International Association for Official Statistics, Mexico.

- The National Standard of Ukraine (2007) Sugar beets, Ukraine 51: 2153-2006.

- Aniskevich LV, Popovich AN (2014) Principles of construction of sowing systems in precision agriculture. Proceedings of the International scientific and technical conference Scientific and technical progress in agricultural production 2: 32-26.

- Abdolahzare Z, Asoodar MA, Kazemi N, Rahnama M, Abdanan SM (2016) Optimization of the most important operational parameters of a pneumatic seeder using real-time monitoring for Cucumber and Watermelon seeds. Journal of Agriculture Machinery 6: 35-48.

- Petrenko MM, Vasylkovsky MI, Vasylkovska KV (2013) Pneumo-mechanical seeding machine. Ukraine.

- Vasylkovska K, Vasylkovskyi O, Leshchenko S, Sviren M, Moroz M (2020) Identification of parameters of pneumatic and mechanical seeding device under the influence of vacuum. Bulgarian Journal of Agricultural Science 25: 1091-1094.

- Vasylkovska KV, Vasylkovskyi OM, Sviren MO, Kulyk HA (2018) Analysis of the works performed by pneumatic and mechanical seeding device without using vacuum. INMATEH – Agricultural Engineering 56: 25-30.

- Vasylkovska KV, Vasylkovskyi OM, Sviren MO, Petrenko DI, Moroz MM (2019) Determining the parameters of the device for inertial removal of excess seed. INMATEH – Agricultural Engineering 57: 135-140.

- Durr C, Boiffin J (2009) Sugar beet seedling growth from germination to first leaf stage. The Journal of Agricultural Science 124: 427-435.

- Firsova MK (1959) Methods for determining the quality of seeds. Moscow: State Publishing House of Agricultural Literature, Russia.

- Firsova MK (1978) Seed viability. Moscow, Russia

- Santos BM (2007) Seed quality and seeding technology. University of Florida Extension Bulletin HS, Florida.

- Ivanov VI (1950) Determination of seed germination with the help of fuchsin. Breeding and seed production 2: 26-29.

- Kostenko O, Lapenko H, Prasolov Y, Lapenko T, Kalinichenko A (2019) Increasing the effectiveness of aggregates for planting sugar beets tecklings to receive elite seeds. Agronomy Research 17: 1649-1664.

- Enrico B, Mitchell MJ, Leonard WP, Robert TL, Piergiorgio S (2010) sugar beet. Root and Tuber Crops 7: 173-219.

- Official site of the State Statistics Services of Ukraine (2022) Official site of the State Statistics Services of Ukraine, Ukraine.

Citation: Vasylkovska K, Oleksii V, Mykola K, Andriienko O, Mostipan M, Halyna K (2023) Analysis of Sowing Quality of Sugar Beet Seeds Before and After Sowing by Pneumatic and Mechanical Seed Meter. J Agron Agri Sci 6: 054

Copyright: © 2023 Kateryna Vasylkovska, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.