Evaluation of Nutrient Solution on the Growth and Yield Performance of Organic Lettuce Grown in Vertical Towers

*Corresponding Author(s):

Dilip NandwaniDepartment Of Agriculture And Environmental Sciences, College Of Agriculture, Human And Natural Sciences, Tennessee State University, Nashville, United States

Tel:+1 6159631897,

Email:dnandwan@tnstate.edu

Abstract

Vertical farming saves land, space, water, produces no weed, pest or disease issues and ecofriendly. In vertical towers, vegetables can be grown indoors and outdoors all year round in short time with less effort, care and greater harvest yield. The objective of this study was to compare the effect of two nutrient blend solutions on the total yield, fresh weight and dry weight of four varieties of lettuce namely Bibb, Leaf lettuce, oak leaf and red salad. The study was conducted in the fall of 2017 in a hoop house at the Tennessee State University organic farm. Organic seeds were directly planted unto 2.5 cm rock wool cubes, in an indoor vertical grow tower. Two concentrations of nutrient blend solution A (2:0:0) and B (0-1-3) evaluated. Indoor vertical towers were spaced 0.9m from each other. At planting, an initial volume of 400mL and 200mL of nutrient blend solution A and B was added into 20 gallons of water to fill the tower garden reservoir. Subsequently, Lettuce plants in tower 1 received 400mL of the nutrient blend solution while lettuce plants in tower 2 were treated with 200mL of nutrient as needed throughout the growing season. Treatment and variety not their interaction had an effect on the growth of the lettuce plants. Yield (fresh wt/g) and dry weight of the Lettuce varieties varied significantly vary from one another. Plant yield was generally higher in the 200mL volume. Fresh and dry weight of red salad bowl lettuce variety with 200mL volume concentration was found to be significantly higher than that of all other varieties grown with the 400mL volume nutrient blend volume. The preliminary study suggest that the grow tower system is a viable alternative to growing lettuce vertically on land and half concentration of nutrient solution (NPK) is optimal for yield performance.

Keywords

Aeroponic; Fresh food; Grow towers; Leafy greens; Mineral concentration; Urban agriculture; Yield

INTRODUCTION

Reports indicate that growing lettuce in an urban tower garden can provide another alternative or avenue of consumption as an act to consume less junk food in the inner cities. Growing vertically in towers is ecofriendly due to efficient system of design, less space and water is used. It would help people live more sustainable lives, save land, water, soil, decrease fossil fuel emission, fertilizer waste [2], as well as pesticide and herbicidal use, and result in an increased yield per unit area of land under cultivation. Aeroponics, a system of vertical farming, is soilless culture such as in a controlled environment like a greenhouse, where roots of plants grown in an enclosed space are bathed regularly with a nutrient rich water solution mix. Some significant benefits to aeroponic vertical towers are higher yields up to 30%, 98% less water, less (up to 90% space) space and reduced or no insect pest and disease problem compared to traditional growing methods [3-5]. Some farmers worry that using a soilless method in growing crops may yield weaker plants requiring a heavier amount of pesticide and producing less nutrients. However, in a 2014 study [6], it was reported that the yield of leafy greens grown in an aeroponic garden system was found to be higher than those grown in soil. Total phenols, flavonoids and antioxidant content were also observed to be higher. Authors saw a 19%, 8%, 65%, and 21% more yield was in basil, chard, red kale, and parsley (leafy vegetables) when grown in aeroponic systems.

Aeroponics does not have large water and nutrient requirements because it involves misting the roots of a plant time and again with a definite quantity the plant could use in the most productive way possible through osmosis to provide nutrients to the plant [7]. The constituents of these nutrients which are composed mainly of soluble salts, are determined by how the plant is grown, environmental conditions, growth media, stage of plant development, how the nutrient is applied and so on [8]. With that being said, though lack of plant nutrients can reduce growth and plant quality, an oversupply of nutrients can also be detrimental to plant health [9]. Individuals and companies who carry out research involving preparation of nutrient rich water have used various concentrations in production. It has been reported that aeroponics produces lettuce plants with better root structures than substrate culture or hydroponic systems [10]. Using a horizontal hydroponic system and a vertical farming system in an indoor controlled environment, [11] researchers have discovered that the “vertical farming system produced increased Lettuce yields per unit of growing floor area when compared with the horizontal”. In addition, their study revealed a significant decline in the fresh weight of lettuce plants from top to bottom in the vertical system and a general uniform yield in the horizontal system [11].

Currently, literature on how lettuce plants respond to nutrient supply in aeroponic systems is scarce. In this present study, four lettuce varieties were grown in a vertical grow-tower in a hoop house at the organic farm in Nashville. The main objective of this study was to evaluate the yield of four lettuce varieties in grow-towers kept indoors and administered with two concentrations of nutrient blend solutions.

MATERIALS AND METHODS

Nutrients were provided using tower garden mineral blend and water with an inbuilt timer and pump to provide the essential nutrients need for proper plant growth and development. The optimal pH of the nutrient blend solution added to the reservoir was maintained at a mildly acidic pH of between 5.0 and 7.0. The nitrogen, phosphorous and potassium ratio for mineral solution A was 2:0:0 while that of mineral solution B was 0-1-3. Nutrient blend solution a (Calcium Nitrate, Iron Sodium EDTA) was made up of 2% total nitrogen, 1% Calcium and 0.05% chelated iron. The ingredients in nutrient blend solution B (Potassium Nitrate, Potassium Sulfate, Magnesium Sulfate, Boric Acid, Copper Sulfate, Manganese Sulfate, Sodium Molybdate, Zinc Sulfate, Phosphoric Acid) was composed of 1.0% phosphate, 3% soluble potash, 0.5% magnesium, 3% Sulphur, 0.01% boron, 0.001% copper, 0.01% manganese, 0.0005% molybdenum and 0.005% zinc. At seed planting, an initial volume of 400mL and 200mL of nutrient blend solution A and B (manufacturer recommended) was required per 20gallons of water. A total volume of 20 gallons needed to be added to each tower to fill the tower garden reservoir. The flow rate was regulated by turning a dial on the pump clockwise or anticlockwise either to minimum or maximum levels respectively. Care was taken when increasing the flow rate towards maximum levels to prevent the nutrient solution from making contact with the cap to avoid a nutrient leak. Subsequently, Lettuce plants in tower 1 received 400mL of the nutrient blend solution while lettuce plants in tower 2 were treated with 200mL of nutrient solution per 20 gallons of water as needed throughout the growing season as recommended by the manufacturer. Generally, a full tank reservoir (20 gallon in volume) lasted for about two weeks and we prepared nutrient blend water mix to add to reservoir when required. We ensured however to keep enough nutrient solution so that at least half of the tank reservoir was filled with water, the pump was always submerged in nutrient solution.

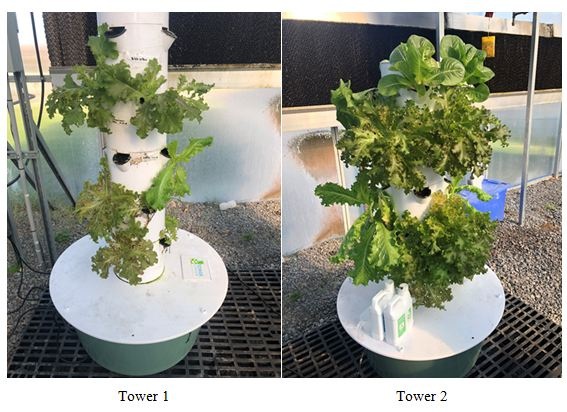

Lettuce varieties were grown and maintained according to the national organic program standards [12]. Plants were observed during various stages of growth and pictures taken. After eight weeks, plants were harvested. The total fresh weight per plant was recorded for each tower. Plants were placed inside an oven set at 60-65ºF for seventy-two hours. Dry weight of plants was measured, and data recorded. Data was collected on fresh and dry weight of lettuce varieties. Analysis of variance (Two-way ANOVA) was conducted by Graphpad 8.0 (To determine multiple comparisons among treatments, varieties and their interactions, Tukey’s Honestly Significant Difference (HSD) post-hoc test were used.

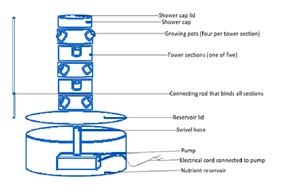

With this efficient system of design, it occupies less space and consumes less water, which ultimately is earth friendly. The vertical tower is usually purchased together with rockwool cubes that are placed in growing pots, mineral nutrient solutions, a pump and a timer amongst others.

RESULTS

Upon observation, using two different quantities to treat each tower the results show the significant effect the solution has as it relates to these leafy greens in a hydroponic vertical tower system (Table 1). The effect of different varieties and treatments on the fresh and dry weight of the lettuce plants and not the interaction between them was significant (p<0.05).

|

Sources |

Fresh wt. (g/plant) |

Dry wt. (g/plant) |

||||

|

DF |

F-value |

p-value |

DF |

F-value |

p-value |

|

|

Variety |

3 |

5.68 |

0.0272 |

3 |

7.57 |

0.0133 |

|

Treatment |

1 |

40.51 |

0.0004 |

1 |

44.79 |

0.0003 |

|

Variety*Treatment |

3 |

3.30 |

0.0874 |

3 |

3.61 |

0.0735 |

|

Errors |

7 |

|

|

7 |

|

|

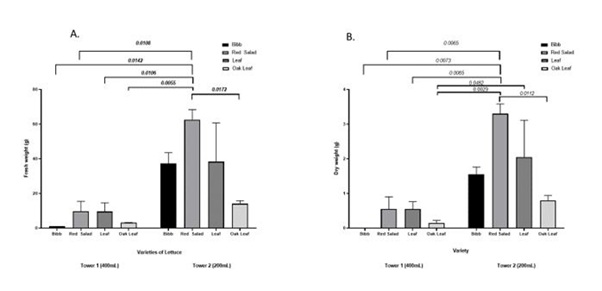

Overall, total yields (Fresh and dry weight) of the Red Salad Bowl Lettuce variety, though not significantly different from Bibb and leaf lettuce, differed significantly from the Oak leaf variety (Figure 3). For the 200ml nutrient blend treatment, the Oak leaf lettuce (14.05g) was the least yielding in terms of fresh weight/g and Red Salad Bowl (62.55g) was the highest. The Bibb lettuce (1g) on the other hand, had the lowest fresh wt/g yields of all the varieties tested when treated with the 400ml nutrient blend solution while Red Salad Bowl had the highest (9.7g).

Per plant yield (Fresh wt./g) was significantly higher in the red salad lettuce (62.55g) grown with the 200mL nutrient blend when compared with the Bibb (1g), red salad bowl (9.7g) , Leaf (9.55g) and oak leaf (3.15g) lettuce varieties produced with the 400mL nutrient blend concentration (Tower 1) (Figure 3). At the same 200mL nutrient blend concentration (Tower 2), red salad bowl lettuce yield (62.55g) was only significantly higher than oak leaf lettuce (14.05g). Its yield did not vary significantly from the Bibb (37.3g) and leaf (38.35g) lettuce yield at the 400ml nutrient blend concentration. Similar result was obtained in for the dry weight of lettuce varieties in both towers (Figure 3). The exception was that the dry weight of leaf lettuce yield (2.05g) in tower 2 (200mL) was significantly higher than the oak leaf lettuce (0.8g) in tower 1 (400mL), and no significant difference observed between their fresh weights.

Figure 3: Main effects of different lettuce varieties and nutrient blend volume on fresh and dry weight of lettuce.

Figure 3: Main effects of different lettuce varieties and nutrient blend volume on fresh and dry weight of lettuce.DISCUSSION

CONCLUSION

ACKNOWLEDGMENT

AUTHOR CONTRIBUTION

CONFLICTS OF INTEREST

REFERENCES

- Fassler J, Cox K (2017) It’s the end of “organic” as we know it. New food economy, NewYorkCity.

- Cavasos R, Domenghini J (2016) Comparison of two hydroponic tower systems for lettuce production. Eastern Kentucky University, Department of Agriculture, Richmond, Kentucky.

- NASA-National Aeronautics and Space administration (2006) Progressive plant growing has business blooming. In: Spin off. Editors- Originating technology/NASA. Publications and graphics department NASA Center for Aerospace Information (CASI). Pg no: 64-67.

- Utami Sri, Darmanto, Jayadi Rachmad (2012) Vertical gardening for vegetables. Acta Horticulturae. Pg no: 195-202.

- Nandwani D, Gunther D (2015) Urban Agriculture: Vertical organic farming. Tennessee State University Cooperative extension, College of Agriculture, Human and Natural Sciences. Pg no: 1-4.

- Chandra S, Khan S, Avula B, Lata H, Yang MH, et al. (2014) Assessment of total phenolic and flavonoid content, antioxidant properties, and yield of aeroponically and conventionally grown leafy vegetables and fruit crops: A comparative study. Evid Based Complement Alternat Med

- Lakhiar Imran Ali, Jianmin Gao, Tabinda Naz Syed, Farman Ali Chandio, Noman Ali Buttar (2018) Modern plant cultivation technologies in agriculture under controlled environment: A review on aeroponics. Journal of plant interactions13: 338-352.

- Guang-jae L, Bo-goo K, Tae-il K, Tae-jung K, Jin-han K (2007) Tomato hydroponics in Korea. Fruit, Vegetables and Cereal Science and Biotechnology 1: 104-109.

- Morgan JB, Connolly EL (2013) Plant-Soil Interactions: Nutrient Uptake. Nature Education Knowledge4: 2.

- Li Qiansheng, Xiaoqiang Li, Bin Tang, Mengmeng Gu (2018) Growth responses and root characteristics of lettuce grown in aeroponics, hydroponics, and substrate culture. Horticulturae 4: 35.

- Touliatos D, Dodd IC, McAinsh M (2016) Vertical farming increases lettuce yield per unit area compared to conventional horizontal hydroponics. Food and energy Security5: 184-191.

- USDA (2015) National organic standards board. United States Department of Agriculture Washington, D.C., USA.

- Jug T, Slamic B (2016) Lettuce growth in extreme conditions. Journal of Food and Agriculture 28: 398-401.

- Blank T (2017) Growing guide: Tower garden by juice plus. Pg no: 1-14.

- Kawasaki Y, Matsuo S, Kanayama Y, Kanahama K (2014) Effect of rootzone heating on root growth and activity, nutrient uptake, and fruit yield of tomato at low air temperatures. J Jpn Soc Hortic Sci 83: 295-301.

- Khater Elsayed (2015) Comparison between hydroponic and aeroponic systems for lettuce production. The 20th Annual Conference of Misr Soc. of Ag. Eng., Egypt.

- Albornoz Francisco, J Heinrich Lieth (2015) Over fertilization limits lettuce productivity because of osmotic stress. Chilean J Agric Res75: 284-290.

- Ding X, Jiang Y, Zhao H, Guo D, He L, et al (2018) Electrical conductivity of nutrient solution influenced photosynthesis, quality, and antioxidant enzyme activity of pakchoi (Brassica campestris L. Chinensis) in a hydroponic system. PLoS Oneg 13: 0202090.

- Sonneveld C, Voogt W (2009) Plant nutrition of greenhouse crops. Springer, New York, USA.

- Bot JL, Adamowicz S, Robin P (1998) Modelling plant nutrition of horticultural crops: A review. Sci Hortic 74: 47 -82.

Citation: Nandwani D, Muhammad T, Nwosisi S, Chowdhury S (2019) Evaluation of Nutrient Solution on the Growth and Yield Performance of Organic Lettuce Grown in Vertical Towers. J Agron Agri Sci 2: 014.

Copyright: © 2019 Dilip Nandwani, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.