Journal of Nanotechnology Nanomedicine & Nanobiotechnology Category: Medical

Type: Perspective

Towards More Stable and Flexible Perovskite Solar Cells by Graphene and Nanotube Contacts

*Corresponding Author(s):

Nima E GorjiSchool Of Electronic Engineering, Dublin City University, Dublin, Ireland

Tel:+353 017007418,

Email:nima.gorji@dcu.ie

Received Date: Jul 27, 2017

Accepted Date: Sep 22, 2017

Published Date: Oct 06, 2017

INTRODUCTION

The R&D of rather stable inorganic-organic hybrid perovskite solar cells have been excessively increasing over the last 5 years. The focus is now on stability of the cells against moisture, a critical aspect to overcome for scaling these devices for large production. One of the techniques to impede water/oxygen ingression to device structure and consequence decomposition of perovskite layer is covering them with protective layers. Graphene and Carbon Nanotubes (CNTs) were suggested as great candidates to this as they offer excellent optical transparency, electrical conductivity. In addition, Graphene and nanotubes have honeycomb networks, which stops ion electro migration of the metallic contacts to the perovskite layer thus significantly reducing the device degradation and shunting probability.

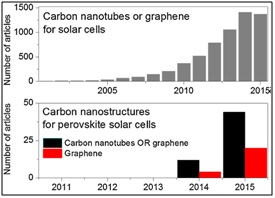

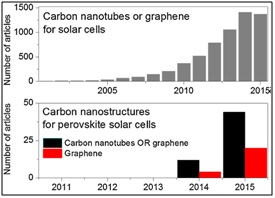

Various research groups worldwide are currently investigating graphene/nanotubes application in the architecture of perovskite solar cells as whole transporting layer, electron transporting layer or even front or back contacts. There were also attempts to mix the perovskite layer with nanotube to enhance its robustness considering the polycrystalline nature of perovskites materials [1]. Nanostructures are flexible and will thus support the flexibility of perovskite devices. In the last 5 years, the application of graphene/nanotubes and other nanostructure such as C60 in perovskite cells was increased according to the chart given in figure 1.

Figure 1: Number of published articles on solar cells based on carbon nanotubes or graphene [2].

In the last 2 years, however, over 1500 papers have been published on graphene/nanotubes application in perovskite devices and various researchers have confirmed that a high performance (15-19%) is obtained from these hybrid cells, which is comparable to the planar perovskite devices [3]. More importantly, hybrid perovskite devices are highly stable (~90% performance after hundred hours stressing), flexible, environmentally friendly and cheaper to produce.

CNT or Graphene derivatives are also influenced by humidity, which deteriorates the device performance. However, novel techniques show that chemical treatment of nanolayers can significantly protect them against oxygen fatigue. Have separately demonstrated that the humidity sensors made of nanotubes showed higher sensitivity and better stability upon proper chemical treatment [4].

Various research groups worldwide are currently investigating graphene/nanotubes application in the architecture of perovskite solar cells as whole transporting layer, electron transporting layer or even front or back contacts. There were also attempts to mix the perovskite layer with nanotube to enhance its robustness considering the polycrystalline nature of perovskites materials [1]. Nanostructures are flexible and will thus support the flexibility of perovskite devices. In the last 5 years, the application of graphene/nanotubes and other nanostructure such as C60 in perovskite cells was increased according to the chart given in figure 1.

Figure 1: Number of published articles on solar cells based on carbon nanotubes or graphene [2].

In the last 2 years, however, over 1500 papers have been published on graphene/nanotubes application in perovskite devices and various researchers have confirmed that a high performance (15-19%) is obtained from these hybrid cells, which is comparable to the planar perovskite devices [3]. More importantly, hybrid perovskite devices are highly stable (~90% performance after hundred hours stressing), flexible, environmentally friendly and cheaper to produce.

CNT or Graphene derivatives are also influenced by humidity, which deteriorates the device performance. However, novel techniques show that chemical treatment of nanolayers can significantly protect them against oxygen fatigue. Have separately demonstrated that the humidity sensors made of nanotubes showed higher sensitivity and better stability upon proper chemical treatment [4].

REFERENCES

- Zhang Y, Tan L, Fu Q, Chen L, Ji T, et al. (2016) Enhancing the grain size of organic halide perovskites by sulfonate-carbon nanotube incorporation in high performance perovskite solar cells. Chem Commun (Camb) 52: 5674-5677.

- Dong Q, Shi Y, Wang K, Li Y, Wang S, et al. (2015) Insight into Perovskite Solar Cells Based on SnO2 Compact Electron-Selective Layer. J Phys Chem C 119: 10212-10217.

- Sun J, Xie X, Bi H, Jia H, Zhu C, et al. (2017) Solution-assisted ultrafast transfer of graphene-based thin films for solar cells and humidity sensors. Nanotechnology 28: 134004.

- Cao CL, Hu CG, Fang L, Wang SX, Tian YS, et al. (2010) Humidity Sensor Based on Multi-Walled Carbon Nanotube thin Films. Journal of Nanomaterials Pg No: 5.

Citation: Gorji NE (2017) Towards More Stable and Flexible Perovskite Solar Cells by Graphene and Nanotube. J Nanotechnol Nanomed Nanobiotechnol 4: 018.

Copyright: © 2017 Nima E Gorji, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Journal Highlights

© 2026, Copyrights Herald Scholarly Open Access. All Rights Reserved!