Coffee Husk Biopellet Characteristics as Solid Fuel for Combustion Stove

*Corresponding Author(s):

Soni Sisbudi HarsonoFaculty Of Agricultural Technology, University Of Jember, East Java, Indonesia

Tel:+62 8533424112, +62 82337912019

Email:s_harsono@yahoo.com

Abstract

As the global population increases, fuel consumption levels will definitely upsurge. The increased demand may lead to fuel crisis, especially on oil products and gas. Evidently, there is need for alternative sources, specifically the renewable ones obtained from natural resources. Even though its quality is affected by moisture content, it can be the best alternative to oil products. The lower level of moisture content creates a better heat value for the product. This study aimed at analyzing the quality of coffee husk biopellet. It focused on the analysis of the moisture and ash contents of 8.32% to 8.91% and 7.05% to 8.07% respectively, along with the calorific value of 16879.45 kJ/kg to process it that do not emit hydrocarbons during combustion.

Keywords

INTRODUCTION

The level of fuel consumption is expected to increase with the growth in human population, a condition that would change the pace of industrial growth in a number of countries. Fuel crisis is likely to emerge if the demand surpasses supply by a large margin, necessitating renewable alternative energy.

One of the most consumed beverage in the world is coffee. There was researh conducted by FAO, estimated that more than 3.5 biliion cups of coffee are used and consumed in the eart every day. Plant of coffee is grown in more than 70 countries. The coffee itself used as beverages which has contribute of waste, such waste water and coffee husk. Traditional forms of growing coffee naturally grew under a shaded canopy of trees. The sheltering from canopies provides a valuable habitat for indigenous animals and insects, as well as prevents topsoil erosion and removes the need for chemical fertilizers. The sun-cultivated coffee, in concert with the necessary addition of fertilizer, creates the highest yield of coffee, but eliminates the diversity of plants, which supports an array of insects and animals, posing detrimental impacts to the biodiversity of the region, as well as other environmental harms.

Indonesia is an agricultural country with a lot of plantations. In this country, coffee is cultivated mostly in smallholder plantations, mainly Arabica and Robusta [1]. Unfortunately, a larger proportion of coffee processing produce wastes. Therefore, to reduce the impact of environmental pollution as a result of wastes, it is necessary to convert the byproducts into something of great value, for example, biomass energy [2].

The level of fuel consumption, especially fossil fuels, will increase along with the increase in the human population and the increasing pace of industry in various countries. Gas and oil production is decreasing every year, but oil and gas consumption continues to increase. Efforts that can be made to anticipate the energy crisis are by processing renewable natural resources as alternative energy sources such as biomass. It will not be difficult to obtain sources of biomass materials in Indonesia”, especially agricultural waste. Plantation and agriculture are highly developed business sectors in Indonesia, this shows a high potential to meet the biomass maker raw material sources [2,3].

The Beurau of Agricultural Research and Development Agency [4] showed therenewable energy sources has potential develop from solid biomass materials in Indonesia at 756.08 million GJ per year. This energy, arround approximatelly 81% (614.6 million GJ per year) from agricultural residues and the rest (141.48 million GJ per year) is come from forestry waste. An example of agricultural waste are coffee husk that could be used as biopellets. The productive area of coffee plantations in Indonesia is about 950,000 hectares and produces around 750,000 tons of coffee per year. In return, the resulting coffee husk waste is 307,500 tons per year as claimed by the Indonesian Coffee Farm [5].

Most of the agricultural land in Indonesia is used for coffee cultivation. Coffee consumption in Indonesia increases every year based on consumer demand. However, the majority of coffee farmers in Indonesia still cannot utilize the coffee processing waste optimally. To reduce the impact of environmental pollution caused by solid and liquid waste from the coffee processing process, efforts are needed to process these wastes into something more valuable for use, namely as a source of biomass energy formation. One of the uses of coffee skin waste with the production of solid biofuel is biopellet [3]. It has a smaller size compared to briquettes. The production, especially coffee husk waste biopellet is rarely found because coffee farmers still have difficulty in determining the composition of the product [6,7].

One way of utilizing the byproducts is by using the dried coffee husk waste as a fuel, the product is called biopellet. It is a solid waste smaller in size than the briquette. The potential of biopellet as energy source cannot be underestimated in Indonesia. This is because as an agricultural economy, the country has abundant sources of biomass, the necessary raw materials [6].

The diversification of uses of byproducts from coffee processing is beneficial in at least three ways. Firstly, it is expected to reduce the negative impacts on the environment. Secondly, there will be an increase in revenue, and thirdly, business opportunities in the coffee sector will significantly increase [6-8].

The quality of biopellet s is influenced by moisture and ash contents. The lower moisture content can increase the calorific value and combustion efficiency. Therefore, the objective of this research was to analyze the quality of coffee husk biopellet using carbonization method with different moisture contents.

METHODOLOGY

Tool and materials

Work procedure

The initial step requires switching on power and waiting for the analyzer complete its self-examination. Check and ensure the weighing is empty and clean. Enter the start button and press “0/T” to define tare boat weight. The display should show weight as “0” as a flashing icon indicates the ready status for loading sample. It then inserted 3 g of the sample and close the cover gently (Figure 1).

The halogen light will start to heat the sample to a steady reading, a process that takes 2 to 30 minutes depending on the sample weight and its moisture content. Record the moisture reading, press stop to end the current testing and clean the weigh boat for future use.

M0 = weight sample as received

M1 = weight dry pan + sample

M2 = weight dry pan + sampleafter drying

Method of measuring ash content (Direct)

In measuring the ash content, the following procedure was followed. First, weigh the sample to approximately 3.0 g into a clean crucible. If the sample (biopellet) being analyzed is a dried test specimen, it should be stored in a desiccator until further use. Record the weight (container plus the sample less tare weight of container) as the initial mass of the test specimen (W2). Place the container and sample in the muffle furnace and ignite to 900°C for a minimum of 3 hours, or until all the carbon is eliminated. Remove the crucible with its sample from the desiccator and cool it to room temperature for 4 hours. Weigh to the nearest 0.1 mg and record this figure. Record the final weight of the ash (W1), as the mass of the container plus ash less container tare weight (Figure 2).

Figure 2: Ash content measurement.

Figure 2: Ash content measurement.

The following procedure was used to measure the heat value. First, pound the sample until it is smooth and put it into the crucible. It then weigh the sample of 1 gram. Measure 8-10 cm for the length of fuse wire. Place fuse wire into the slot and bend it to a ‘U’ shape. Place empty crucible into analytical balance and tare. Weigh 1 gram standard benzoic acid into the crucible. Place the crucible with its contents into the sample holder and bend the U-shape fuse wire close to the benzoic acid standard. Seal the combustion chamber with bomb cap and close the needle valve. Fill with pure oxygen up to 420 psi. Fill the bomb bucket with 2 L of distilled water from 2 L pipet tank (make sure the water flows into the bucket wall to prevent air bubbles).

Place the combustion chamber into bomb bucket. Attach electrical leads to the chamber. Press select key and type the weight of sample and length of fuse. Kickoff the bomb calorimeter by pressing the start key (the analysis starts with pre-fire for 3 minutes, firing for 0.1 minutes, and post fire for 5 minutes). After the analysis ends, take out the combustion chamber from the bucket and release the gas, open it to check the incomplete burning of fuse wire. Measure the length of the remaining fuse wire. Edit the last result of fuse fire. This is done by selecting the menu key and select edit last result (no. 6 key), then key in the length of burnt fuse wire. Press exit key to get the final result (Figure 3).

Figure 3: Bomb calorimeter measurement.

Figure 3: Bomb calorimeter measurement.RESULTS AND DISCUSSION

Raw material characteristics

|

Type of Analysis |

Parameters |

Result (%) |

|

1 |

Water content |

2.25 |

|

2 |

Ash content |

0.73 |

|

3 |

Volatile matters |

74.20 |

|

m1 (g) |

m2(g) |

m3(g) |

Moisture Content (%) |

|

1.003 |

0.914 |

0.089 |

8.900 |

|

1.006 |

0.918 |

0.088 |

8.800 |

|

1.008 |

0.925 |

0,083 |

8.300 |

|

|

|

Average |

8.670 |

Table 2: The moisture content.

Moisture content

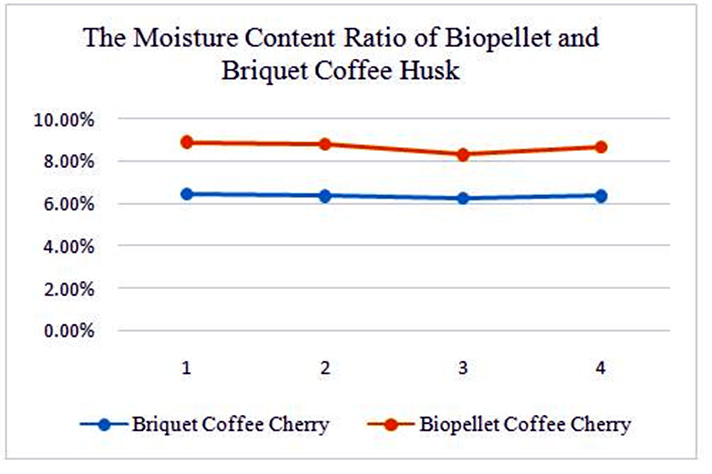

Figure 4: The ratio of moisture content biopellet coffee husk.

Figure 4: The ratio of moisture content biopellet coffee husk.There was a difference in the initial moisture content of the coffee husk briquette and biopellet. The preliminary value of briquettes in the hot air chamber when using drying machine was much lower compared to the solar drying sample. While using moisture analyzer, the content was 8.67%. This was different from the one in briquettes within the hot chamber air that had 6.34%. Moreover, the difference in value between biopellet and briquettes of coffee husk was 4.62%. It is imperative to note that the moisture value of biopellet was meant to fulfill the New Europe Pellet Standard-EN 14961-1. Notably, the higher moisture content required more energy to evaporate water. The needed energy to ignite the biopellet increased, causing the fuel to react during combustion. With a higher moisture content, the quality of biopellet decreases.

Ash content

|

Replication |

W1 (g) |

W2 (g) |

Ash (%) |

|

1 |

0.2107 |

3.0075 |

7.005 |

|

2 |

0.2495 |

3.0330 |

8.266 |

|

3 |

0.2740 |

3,0508 |

8.981 |

|

|

|

Average |

8.071 |

Calorific value

|

Paremeter |

Replication |

||

|

|

1 |

2 |

3 |

|

Weight (g) |

1.01 |

1.01 |

1.01 |

|

Fuse wire 1 (cm) |

9.80 |

10.01 |

10.01 |

|

Δ Fuse wire (cm) |

6.41 |

7.22 |

7.51 |

|

Δ T (pre-fire) (° C) |

1.68 |

1.62 |

1.70 |

|

Oxygen (Psi) |

420.00 |

420.00 |

420.00 |

|

Calorific value (cal/g) |

3951.50 |

3932.90 |

4230.10 |

CONCLUSION

Coffee husk can be used as an alternative energy source by carbonization process when converted into biopellet. The physical properties of the biopellet complied with most of the set standards. The results of this exercise showed the quality of coffee husk biopellet obtained from drying with sunlight was low. The moisture and ash contents in the analyzer were 8.67% and 8.07% respectively. The calorific value, 16897.54 kJ kg-1 was lower than the calorific value standards.

ACKNOWLEDGEMENT

This research was supported by the Indonesian Government as a Project CPPBT-Ministry of Research and Higher Education, The Republic of Indonesia, 2017.

REFERENCES

- Widyotomo S (2013) Potency and technology of coffee trash diversification product to increase e good quality and added value. Coffee and Cocoa Research Review 1: 63-80.

- Tajalli A (2015) Panduan penilaian potensi biomassa sebagai sumber energi alternatif di Indonesia. Penabulu Alliance, Jakarta, Indonesia.

- Harsono SS, Prayogo B, Tasliman, Mel M , Ridha F (2018) Effect of holes system designing for lowe energy stove using coffee husk biopelet as solid fuel. Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 51: 215-226.

- National Energy Council (2014) Ketahanan Energi Indonesia 2014. Jakarta: 6. Republic of Indonesian National Energy Council.

- USDA Foreingn Agricultural Service (2017) Indonesia: Coffee annual, USDA Foreingn Agricultural Service, Jakarta, Indonesia.

- Cubero-Abarca R, Moya R, Valaret J, Filho MT (2014) Use of (Coffea arabica) pulp for the production of briquettes and pellets for heat generation. Science and Agrotechnology 38: 461-470.

- Pujol D, Liu C, Gominho J (2013) The chemical composition of exhausted coffee waste. Industrial Corps and Products 50: 423-429.

- Yokoyama S, Matsumura Y (2008) Asian biomass handbook. Journal of the Japan Institute of Energy, Tokyo, Japan.

Citation: Harsono SS, Dila R, Mel M (2019) Coffee Husk Biopellet Characteristics as Solid Fuel for Combustion Stove. J Environ Sci Curr Res 2: 004.

Copyright: © 2019 Soni Sisbudi Harsono, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.