Environmental Impacts and its Concerns due to Accidents in Oil& Gas Pipelines around India-a Mini review

*Corresponding Author(s):

Priyanka EBDepartment Of Mechatronics Engineering, Kongu Engineering College, Perundurai, India

Email:priyankabhaskaran1993@gmail.com

Abstract

Risk Assessment is an extremely useful tool in providing a framework in which to identify the possible hazards and evaluate the risks associated with all crude oil pipelines. Fluid transmission risks are associated with constant dynamic loads on the system and instability of the process. A large number of connecting fittings creates an additional danger of piping integrity's loss. It was found that, on average, 85% of product released after an accident remained unrecovered,53% of accidents led to soil contamination, 41% of accidents impacted environmentally sensitive areas, and 92% of water crossing pipelines involved in accidents were uncased. Pressure drops, dynamic and static loads create good conditions for the deformation aging of metal. From this point of view, the oil transportation by pipeline is the greatest danger, since this substance is characterized by the formation of two-phase flow, the existing of pulsation flow, the formation of shock waves and discharge zones. Hence this paper address about the influences of accident on the environments situated around the oil pipelines and its severity on the economy with respect to the human life.

Keywords

Accidents; Environmental impacts; Oil pipelines

INTRODUCTION

Nowadays, the oil industry gives great attention to providing the reliability and safety during the construction and operation of main pipelines. Despite this fact, the emergency situations associated with oil transportation by pipelines occur very often [1-4]. In general, such accidents include high material costs for the oil pipeline’s operating companies and significant damage to the environment, people, and property in the vicinity of the failure pipelines. Therefore, the decreasing of the probability of emergency situations on the main oil pipelines is one of the immediate issues in this field. The problem is especially important for pipelines, which are located and operated in special climatic conditions. The main factors, which contribute to the emergency occurrence, are the following: the usage of significant amounts of flammable and explosive substances in operating procedure; the existence of mechanical impurities in oil, causing abrasion of equipment and pipelines; operating procedure under pressure; harsh climatic conditions and others.

Pre-accident analysis is an important aspect of emergency oil spills problem. The main causes of oil pipelines accidents are pipeline corrosion (including internal and external), construction defects, mechanical damage (including excavation work), diversions, unauthorized junctions, third party activity, oil pipelines' operational imperfection, manufacturing defects of pipes and equipment, natural disasters [5-9]. During the oil transportation, the loss of piping integrity may occur, which would lead to release of hazardous substances into environment. The main result of such accident is the transported oil leakage, which creates toxic pollution of the environment (water, air and soil). Moreover, as a result of spilled oil evaporation the cloud of fuel-air mixture is formed. The presence of ignition source within the cloud may lead to its inflammation. The highest risk of accidents on pipelines is connected with longitudinal damages. They can occur during the formation of corrosive gas pocket or guillotine ruptures both on the base part of pipe and in the zone of welding joints. Therefore, the loss of piping integrity is considered as the most frequent initiating event, which causes the hazardous substance’s release into environment [10-13]. The loss of piping integrity mode influences the types of leakage. If discharge area is small, relatively longtime liquid outflow through a hole is observed. On the other hand, if pipeline integrity damage is significant, considerable volumes of hazardous substance reach environment immediately.

THE MAIN CHALLENGING ISSUES ON OIL PIPELINE TRANSPORTATION IN INDIA

Although the Pipeline and Hazardous Materials Safety Administration (PHMSA) has standard baseline incident frequencies to estimate the number of spills, TransCanada altered these assumptions based on improved pipeline design, operation, and safety. Whether these adjustments are justified is debatable as these assumptions resulted in a nearly 10-fold decrease in spill estimates. Given that the pipeline crosses 247 miles of the Ogallala Aquifer, or 14.5% of the entire pipeline length, and the 50-year life of the entire pipeline is expected to have between 11 - 91 spills approximately 1.6 - 13.2 spills can be expected to occur over the aquifer. An estimate of 13.2 spills over the aquifer, each lasting 14 days, results in 184 days of potential exposure over the 50 year lifetime of the pipeline. In the reduced-scope worst-case exposure scenario, the volume of a pinhole leak at 1.5% of max flow-rate for 14 days has been estimated at 189,000 barrels or 7.9 million gallons of oil. According to PHMSA's incident database, only 0.5% of all spills in the last 10 years were >10,000 barrels. The introduction of benzene and other volatile organic compounds (collectively BTEX) to the subterranean environment compounds the threat posed by a pipeline leak. Particularly if followed by rain, a pipeline breach would result in BTEX dissolution and equilibration of benzene in water, followed by percolation of the admixture into the aquifer. Benzene can cause many health problems and is carcinogenic with EPA Maximum Contaminant Level (MCL) set at 5 μg/L for potable water. Although it is not well studied, single benzene exposure events have been linked to acute carcinogenesis. Additionally, the exposure of livestock, mainly cattle, to benzene has been shown to cause many health issues, such as neurotoxicity, fetal damage and fatal poisoning [14].

The entire surface of an above-ground pipeline can be directly examined for material breach. Pooled petroleum is unambiguous, readily spotted, and indicates the location of required repairs. Because the effectiveness of remote inspection is limited by the cost of monitoring equipment, gaps between sensors, and data that requires interpretation, small leaks in buried pipe can sometimes go undetected. Pipeline developers do not always prioritize effective surveillance against leaks. Buried pipes draw fewer complaints. They are insulated from extremes in ambient temperature, they are shielded from ultraviolet rays, and they are less exposed to photodegradation. Buried pipes are isolated from airborne debris and acid rain. They are protected from nesting birds, rutting mammals, and stray buckshot. Buried pipe is less vulnerable to accident damage (e.g. automobile collisions) and less accessible to vandals, saboteurs, and terrorists [15].

STATISTICAL ANNALYSIS FOR ESTIMATING ACCIDENT RATES IN OIL PIPELINES

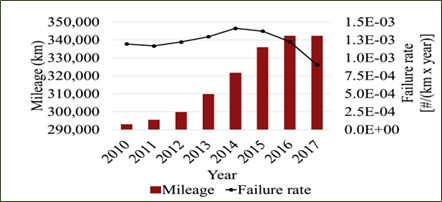

The total cost of an accident is the sum of the estimated costs of public and non-operator private property damage paid or reimbursed by the operator, loss of product released unintentionally and during intentional and controlled blow down, operator’s property damage and repairs, emergency response, and environmental remediation. This study estimates the cost of environmental remediation as a percentage of the total cost of an accident. The hazardous liquid pipeline network has grown from 292,879 km in 2010 to342, 204 km in 2016, as shown in Figure 1, which is an increase of about 14% (49,325 km) over the 7 years.

Figure 1: Annual hazardous liquid pipeline mileage and failure rate for hazardous liquid pipelines [16-18].

Figure 1: Annual hazardous liquid pipeline mileage and failure rate for hazardous liquid pipelines [16-18].

The highest annual average volume released between 2010 and 2017 was 1,394 barrels in 2013. The peak observed in 2013 was due to 4 large hazardous liquid releases: 20,600 barrels of crude oil were released in North side-oriented pipelines, 18,400 barrels of ethane/propane mix were released in south side, 11,405 barrels of liquefied petroleum gas in Cochin, and 23,702 barrels of the same product in Bangalore. On average, 85.2% (30%) of released product remained unrecovered after an accident [18].

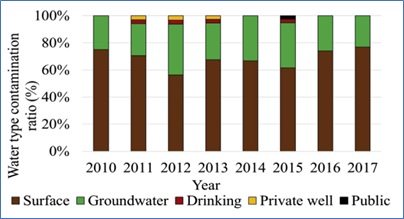

Figure 2: Annual ratio of water type contamination due to hazardous liquid pipeline accidents [16]

Figure 2: Annual ratio of water type contamination due to hazardous liquid pipeline accidents [16]

Figure 2 shows the surface water was the most often contaminated water type (68%), followed by ground water (29%), drinking water and private well water (1%), and public water(<1%).The PHMSA database reports no missing information for water contamination; how-ever, information about soil contamination is often missing for the years 2010through 2014. On average, 53% (6%) of accidents lead to soil contamination. The details of impacts related to soil contamination (e.g. volume or area of contaminated soil) are not recorded in the database provided by PHMSA and, for this reason, it is not possible to evaluate the magnitude of the environmental impact on soil due to hazardous liquid pipeline failures [16].

IMPLEMENTATION OF APPROACHES FOR RISK ASSESSMENTS

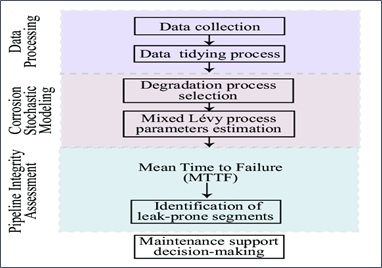

Nowadays there are several approaches to risk assessment: phenomenological, deterministic, expert and probabilistic. Phenomenological approach is based on emergencies possibility determination using the analysis results that represent conditions connected with the nature laws. This approach is the easiest one to use and gives reliable results, if operating processes have sufficient margin to limiting levels. However, it is unreliable, when abrupt change of substances or systems occurs. This approach is preferable to compare the safety margins of different potentially dangerous objects and is useless in analysis of emergencies, which depends on reliability of different parts of the object or its safety facilities. Figure 3 shows the dynamic risk assessment conceptual frame layout.

Figure 3: Conceptual layout of dynamic risk assessment.

Figure 3: Conceptual layout of dynamic risk assessment.

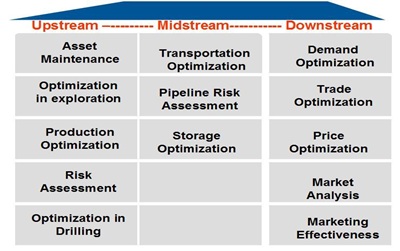

Deterministic approach provides an analysis of the sequence of the accident development from the initial event through a series of suggested failures. Emergency process is studied and predicted with the help of mathematical modeling, construction of simulation models and complex calculations. Disadvantages of this approach include the gaps in some important events in accident development; difficulty in adequate mathematical models construction; complexity and high cost of experimental studies to validate computer models. Expert approach is based on obtaining quantitative risk assessments by processing of experts' opinions. The main disadvantage of this approach is the necessity to analyze the objectivity and reliability of experts’ opinions. Figure 4 describes about the predictive analysis sequences to be done in oil and gas pipeline industry.

Figure 4: Predictive analytics steps to be carried out in pipeline system.

Figure 4: Predictive analytics steps to be carried out in pipeline system.

The probabilistic approach involves the probability assessment of the accident. This approach allows analyzing the chain of events and equipment failures and estimating the total probability of accident. Main disadvantage of this approach is related to the lack of statistics on equipment failure. In addition the usage of simplified design schemes reduces the reliability of the risk assessment for serious accidents. However, this approach currently is considered as one of the most perspective ones. In this paper probabilistic approach was used. Its application can be explained by capacity to model all possible pipeline accident scenarios. Different techniques (statistical data, event tree analysis, fault tree analysis, etc.) allows to identify and quantify all scenarios, as well as to determine the protective actions if emergency occurs.

DISCUSSION AND CONCLUSION

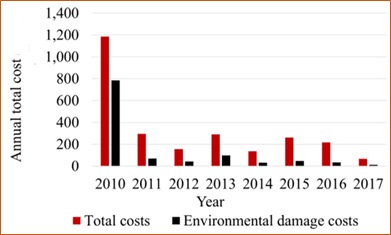

PHMSA gathers information about total costs associated with hazardous liquid pipe-line accidents. The total costs are divided into various types in which Figure 5 that, on average, from an annual total cost, environmental damage and remediation cost hazardous liquid pipeline operators per year. The peak observed in 2010 is due to the which resulted in the highest total and environmental damage costs from pipeline spills recorded between 2010 and 2017. On average, 28% (7%) of the total costs of accidents are due to environmental damage and remediation [17].

Figure 5: Annual total environmental damage costs due to hazardous liquid pipeline accidents [17].

Figure 5: Annual total environmental damage costs due to hazardous liquid pipeline accidents [17].

A large portion of the volume released to the environment as a result of pipeline failures and releases often remains unrecovered and dispersed in the environment. Additional actions should be taken to reduce the amount of unrecovered product and increase soil remediation rates. The PHMSA database did not include reasons for not remediating soil after a spill or for failing to more effectively recover the released product. By containing the dispersion of the material in the environment or improving spill detection systems, it is possible to reduce environmental damage and related costs. It is considered that the initiating event is the loss of piping integrity due to rupture or puncture of pipeline's section. The output event forms such adverse factors as thermal radiation (for oil spill fire) or blast overpressure (for oil vapor explosion).

The results of this research include the following: -The main reason of oil pipeline accident is depreciation and metal corrosion, which are caused as well as by local climate conditions. -The most dangerous are the pipeline's sections, which have intersections with water bodies. The ecological damage is the main adverse effect for such accidents. -The lethal injury for pipeline's servicers is possible during pipeline inspection or construction and assembling operations, if the time of their presence and accident occurrence will match. -The obtained individual, societal, public and potential risks can be compared with acceptable values.

CONFLICT OF INTEREST

All the contributors in this research work have no clashes of attention to announce and broadcasting this article.

ACKNOWLEDGEMENT

This research work is carried out under the Senior Research fellowship received from CSIR (Council for Scientific and Industrial Research) with grant no.678/08(0001)2k18 EMR-I.

REFERENCES

- Priyanka EB, Maheswari C, Meenakshipriya B (2016) Parameter monitoring and control during petrol transportation using PLC based PID controller. Journal of Applied Research and Technology 14: 125-131.

- Priyanka EB, Maheswari C, Thangavel S (2018) Remote monitoring and control of an oil pipeline transportation system using a Fuzzy-PID Flow Measurement and Instrumentation 62: 144-151.

- Priyanka EB, Maheswari C, Thangavel S (2018) IoT based field parameters monitoring and control in press shop assembly. Internet of Things 3: 1-11.

- Priyanka EB, Maheswari C, Thangavel S (2019) Remote monitoring and control of LQR-PI controller parameters for an oil pipeline transport system. Proceedings of the Institution of Mechanical Engineers, Part I: Journal of Systems and Control Engineering, 233: 597-608.

- Priyanka EB, Maheswari C, Thangavel S (2018) Proactive Decision Making Based IoT Framework for an Oil Pipeline Transportation System. InInternational conference on Computer Networks, Big data and IoT 31: 108-119.

- Priyanka EB, Krishnamurthy K, Maheswari C (2016) Remote monitoring and control of pressure and flow in oil pipelines transport system using PLC based controller. In 2016 Online International Conference on Green Engineering and Technologies (IC-GET) (IEEE) 31: 1-6.

- Subramaniam T, Bhaskaran P (2019) Local intelligence for remote surveillance and control of flow in fluid transportation system. Advances in Modelling and Analysis C 74:15-21.

- Priyanka E, Maheswari C, Ponnibala M, Thangavel S (2019) SCADA Based Remote Monitoring and Control of Pressure & Flow in Fluid Transport System Using IMC-PID Controller. Advances in Systems Science and Applications 19: 140-162.

- Priyanka EB, Thangavel S (2019) Fault Identification by Extreme Pressure in Oil Pipelines using Artificial Neural Network, International Journal of Engineering and Advanced Technology 8: 90-96.

- Chenniappan M, Priyanka EB, Thangavel S, Parameswari P (2019) Development of unmanned guided vehicle for material handling automation for industry 4.0. International Journal of Recent Technology and Engineering 7: 428-437.

- RBN Energy (2018) Pending Crude Oil Pipeline Projects. RBN Energy Texas, USA.

- Belvederesi C, Thompson MS, Komers PE (2017) Canada’s federal database isinadequate for the assessment of environmental consequences of oil and gaspipeline failures. Environ Rev 25: 415.

- Hu G, Zhang P, Wang G, Zhang M, Li M (2017) The influence of rubber material on sealing performance of packing element in compression packer. J Nat Gas Sci Eng 38: 120-138.

- Wang H, Xu J, Sheng L, Liu X (2018) Effect of addition of biogas slurry for anaerobic fermentation of deer manure on biogas production. Energy 165: 411-418.

- He BJ, Zhao DX, Zhu J, Darko A, Gou ZH (2018) Promoting and implementing urban sustainability in

China: An integration of sustainable initiatives at different urban scales. Habitat Int 82: 83-93. - Liu H, Cheng Y (2017) Mechanism of microbiologically influenced corrosion of X52 pipeline steel in a wet soil containing sulfate-reduced bacteria. Electrochim Acta 253: 368-378.

- Zhao D, Zhao X, Khongnawang T, Arshad M, Triantafilis J (2018) A Vis-NIR spectral library to predict clay in Australian cotton growing soil. Soil Sci Soc Am 82: 1347-1357.

- Alvarado-Franco JP, Castro D, Estrada N (2017) Quantitative-mechanistic model for assessing landslide probability and pipeline failure probability due to landslides. Eng Geol 222: 212-224.

Citation: Priyanka EB, Thangavel S (2020) Environmental Impacts and its Concerns due to Accidents in Oil& Gas Pipelines around India-a Minireview. J Atmos Earth Sci 4: 015.

Copyright: © 2020 Priyanka EB, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.