Utilization of Fly Ash for Sustainable Environment Management Haldia Energy Limited, Haldia, West Bengal, India

*Corresponding Author(s):

Sanjoy ChakrabortyChief Manager, Environment Department, Haldia Energy Limited Baneswarchak, Haldia, Ditrict: Purba Medinipur, West Bengal, India

Email:sanjoy.chakraborty@rpsg.in

Abstract

Fly ash is a fine powder generated during the burning of pulverized coal in thermal power plants. This industrial waste may create significant environmental problems when released into the atmosphere. In the past, vast majority of the material generated each year was held in ash dams or similar dumps but in recent years a number of technologies have been developed for the beneficial utilization of fly ash in different fields. Hence, to mitigate these impacts, Haldia Energy Limited (HEL) has undertaken eco-friendly manners for Fly ash utilization since its inception to reduce the environmental pollution impacts.

Introduction

Haldia Energy Limited (HEL) a leading power generation company of RP-Sanjiv Goenka Group has set up a 2 x 300 MW coal based thermal power plant at Baneswarchak, Haldia, Purba Medinipur, West Bengal. All the 02 Units of the power plant have been commissioned between January 2015 to February 2015. For the consumptive water use in the power plant a water intake pump house has been constructed on River Hooghly which is about 14 km distance from the plant.

One of the important aspects of any coal-based TPPs is the necessity of the combustion of coal. However, coal combustion generates two categories of by-products i.e., bottom ash and fly ash. Indian coal is of low grade having very high ash content in the range of 30-55%. Bottom ash is collected at the bottom of the boiler. While fly ash is collected in the electrostatic precipitators and then transported pneumatically to the fly ash silos. Generally, the combustion of coal produced 10% of by-products in the form of bottom ash and 90% in the form of fly ash.

Thus, fly ash generation is significantly large in quantity than bottom ash. Therefore, the utilization of fly ash that has been generated in huge quantities is a challenge. A large number of technics and methods have been developed for the gainful utilization and safe management of fly ash.

Fly ash characterization

Depending upon the source and makeup of the coal being burnt, the composition of fly ash and bottom ash varies considerably. Fly ash includes substantial amounts of silicon dioxide and calcium oxide which are the main ingredients of many coal-bearing rocks. The operation of coal burners, together with the setting of the coal mills and their classifiers, affects the percentage of unburned carbon (UBC) in the fly ash. The use of Lo NOx burners increases this percentage, and causes re-entrainment and increased sparking in the precipitator. Further, the UBC tends to absorb SO3, which in turn increases the fly ash resistivity. Elemental constituents of fly ash depend upon the specific coal bed makeup, but may include one or more of the following elements in quantities or trace amounts to varying percentages: Arsenic, molybdenum, selenium, cadmium, boron, chromium, lead, manganese, mercury, strontium, thallium, vanadium, beryllium along with dioxins.

Utilization Of Fly Ash By HEL In Different Sectors

The main purpose of the utilization of Fly ash is to minimize the environmental pollution which can occur from its disposal. Instead of this, there are also some other reasons for its utilization:

(i) There may be some economic gain from the sale of the by-products.

(ii) The by-products can replace some scarce or expensive natural resources.

(iii) Disposal costs can be minimized, etc.

HEL Plant management is focused on the effective utilization of Fly Ash generated at site since its inception. For achieving 100% dry Ash utilization, Fly ash is collected pneumatically in dry form and stored in the dry fly ash silo of a capacity of 2000 m3 each and is being used for various purposes, some of them which discussed as follows:

Supply of fly ash to the cement manufacturing industry

To make dry Fly Ash available to end users for cement manufacturing, suitable dry Fly Ash extraction and storage silos have been installed at HEL. To facilitate bulk transportation of Fly Ash through the Riverine route ( India-Bangladesh), which is presently the cheapest option for bulk transportation, loading& unloading facilities have been developed at Haldia Port and Bangladesh sites. HEL’S Bulk transportation of Fly Ash through the Riverine route is in a closed and environment-friendly manner.

Fly ash, generated from HEL is utilized by cement industries in neighboring Bangladesh.

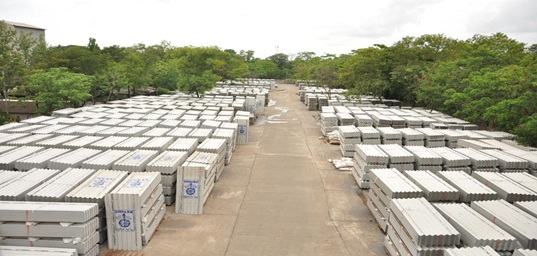

Supply of fly ash to ash-based product manufacturing industries

To promote the use of Fly Ash bricks & blocks in construction, HEL is being supplied Fly ash to different nearby industries on regular basis. These bricks & blocks are being utilized in various construction activities exclusively.

Fly ash use construction material in road construction

Fly ash use construction material in road construction

The use of fly ash is being increasingly promoted in the road sector, where it is mostly used for the construction of roads, embankments and flyovers.

Fly ash use in agriculture field

To promote the use of Fly Ash in Agriculture, The organization started smart environment-friendly handling of fly ash. Along with Bidhan Chandra Krishi Viswabidyalaya, Kalyani, the company started farming on ash beds in an area of approx. 1500 m2 in place of soil.

Conclusion

The disposal of fly ash from coal-fired power stations causes significant economic and environmental problems. Although fly ash causes environmental pollution, it is an important raw material for various applications. Poor public awareness about the products, lack of proper coordination between thermal plants and ash users etc. are the cause of low-level utilization of fly ash. But nowadays the utilization of fly ash has been increasing nationally wise.

HEL 100 % fly ash utilization in a different field such as Cement Manufacturing, Ash based products, Construction activities etc. clearly shows that waste material can be used as a potential resource material in various fields and also to minimize the environmental hazards which can occur from its disposal

Citation: Dutta S, Chakraborty S, Dwivedi LP (2022) Utilization of Fly ash for Sustainable Environment Management Haldia Energy Limited, Haldia, West Bengal, India. J Environ Sci Curr Res 5: 035.

Copyright: © 2022 Somnath Dutta, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.