Small Scale Fresh Water Aquaponics as Solution in Deserted and Arid Areas

*Corresponding Author(s):

Efstathios LampakisIchthyologist Aquaculture Specialist And Aquaponics Consultant, Technological Institute Of Aquaculture, Abu Dhabi, United Arab Emirates

Tel:+971 525070160; 02 4490800,

Email:stathisstoi@yahoo.gr, elampakis@motifdesign.ae

Abstract

Keywords

INTRODUCTION

Due to the well-known problem of water scarcity, the necessity of innovated practices is a must wherever the water is going to be used. Humans, Animals and Plants we all need water in order to survive, Aquaponics could be a solution and a connection key element by using the water in an integrated way. Aquaponics is an integrated multi-trophic system that combines elements of recirculating aquaculture and hydroponics [1-3]. A lot of different sources of fresh water are available and each of them must be used on the most efficient way. Aquaponics is offers supportive and collaborative methods of vegetables and fish production and can grow substantial amounts of food in locations and situations where soil-based agriculture is difficult or impossible [4]. In most deserted countries such as United Arab Emirates most of the water is coming from desalination units or boreholes. Both sources have some limitations that must be overcome or eliminated in order to cover the needs as longer as could be. Successful cultivation practices such as Hydroponics or argillic clay and water recirculation are very promising but are not giving an integrated solution to this major problem.

A full integrated system based on aquaponics seems to be a solution

The creation of Aquaponics for agriculture purposes for both salt and fresh water and the reuse of the water as many times as could be is a must in any arid and deserted area, where the scarcity of water is the main issue that the farmers are facing down. The purpose of this article is to present a simplified and practically applicable model based on practical results collected by small and medium-sized farms in the Emirates region. Following simple measurement practices in collection of basic physio-chemical parameters, such as Oxygen, Temperature pH, Ammonia, Nitrite and Nitrate and applying the necessary adjustments, could be achieved a stable and productive from any prospective farmer Aquaponics system. According to the collected results, it is possible to obtain Aquaponics production of fish and vegetables, by following simple monitoring procedures that are feasible by any future farmer. Adjustment in the system as per the findings is essential and have to be followed on daily basis.

In the presented model has taken into account the minimization of water needs for an environmentally friendly cultivation system.

OBJECTIVE AND SCOPE

AQUAPONICS DEFINITION

By its nature RAS is flexible and adaptable to the local conditions related to the water source and water temperature and salinity and could implement in most of the cases successfully. The waste of the aquatic animals are converted by the bacteria who are built in the system, (Bio-filter) into nutrients, and will irrigate fresh water and salt water plants accordingly.

In case of desalination units two lines of fish production could be established, Fresh water and Salt water Aquaponics. Both systems could be run in RAS by using the minimum of new added into the systems water, just enough for the irrigation needs of the farm and cover of the evaporation. From the fresh water line could be irrigate vegetable and herbs cultures and from the salt water fish culture will be irrigated Halophytic cultures mostly Salicornia as it seems to be the most promising. If any excess water is existing could be collected from both systems and be used for irrigation in Palm trees or other semi-salt tolerant trees. The Aqua-ponically production idea could be work as home modular small farm enough to cover the needs of a family or as a commercial farm with production as per the requirement.

Small scale aquaponics farm

In the UAE, many local farmers implement small Aquaponics units using basic knowledge. This article aims to present a familiar home-based, fresh water Aquaponics model, using simple but high-level practice and reasonable equipment cost. At this small scale, the Aquaponics model could easily produce 150-200 kg of fish per season and a variety of vegetables, lettuce, cucumber, tomatoes and herbs up to 50 kg a month.

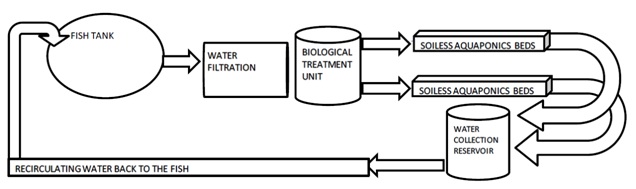

SYSTEM DESCRIPTION

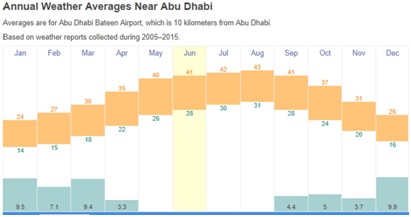

The necessary area for a small unit is about 400 m2 covered by 60% shade in the plants cultivation area and 80-90% shaded above the Aquaculture part, including the fish tank and the treatment area. The farm will be capable to operate about 8 months a year, starting on September ending on May when the environmental temperature is relative low in UAE.

The system consist of

- Fish tank about 4 m3 for the fish culture

- Sedimentation tank, as mechanical filtration and particle remover

- Bio-filter

- Aeration system, through an air blower (0.8-1.0KW) for the air supply

- Air diffusers in all the components, to maintain the oxygen level

- Culture beds

The chosen fish for this model is Tilapia spp because is a tolerant and easy cultured specie in both fresh and salty water. The species and hybrids of tilapia that are widely cultured can often survive and even thrive under environmental conditions that many other fishes would be unable to tolerate… are tolerances for low dissolved oxygen and a wide range of both salinity and temperatures. In the case of temperature, however, tilapia are tropical fishes, so they are susceptible to diseases and death at low temperatures. While most tilapia culture is conducted in tropical or subtropical regions, tilapia are also cultured in temperate regions where warm water is available [8]. Almost all the vegetables and herbs could be produced. The proposed for this system are leafy vegetables, Lettuce, Cucumber, Tomatoes, and herbs such as Basil, Coriander, Parsley, Mint.

OBJECTIVE & SCOPE

METHODOLOGY AND DATA COLLECTION SYSTEM

|

Parameter |

Inlet to the Fish Tank Water |

Outlet of the Fish Tank Water |

After the Biofilter |

Outlet of the Culture Beds |

|

Water Oxygen Level |

? |

? |

? |

? |

|

Water Temperature |

? |

? |

? |

? |

|

Water pH Level |

? |

? |

? |

? |

|

Ammonia, Nitrite and Nitrate |

|

|

? |

? |

According to the collected data at the above given check point it is easy to evaluate the productivity and the dynamic of the system and farther more to do the necessary adjustments. The monitoring equipment have to be easy to use and simple to their maintenance. It is proposed the oxygen-meter and the pH meter to be of high precision, from companies such as OxyGuard, Hanna, YSI, or others commonly used in Aquaculture. For the air temperature a minimum-maximum thermometer have to be placed inside and outside of the net-house. A simple on use Ammonia kit is enough to check the system in all the steps.

Special attention have to be given to the position of the thermometer, must be placed in a shaded place avoid the direct sunlight. The monitoring system and the collected data are giving the opportunity to adjust the parameters as per the needs on real time. They can also be used as reference by any prospective farmer in similar conditions.

DATA COLLECTION

In Aquaponics the correlation between Oxygen and pH is an important factor. A strong aeration can increase the oxygen levels but is also increasing the pH, which is not desired for the vegetables. The oxygen levels have to be kept in the Fish tank and crops in a levels more than 4.0 ppm enough to cover the needs of both and keep the pH levels in the range of 6.2-7.2. A pH of 7.5 can lead to nutrient deficiencies of iron, phosphorus and manganese… Nitrifying bacteria experience difficult below a pH of 6, and the bacteria’s capacity to convert ammonia into nitrate reduces in acidic, low pH conditions [4]. On daily basis Oxygen and pH have to be measured in a signed points twice a day. The points and the reason why we need these measurements are describing as below.

- Before fish tank (inlet water) in order to know what is the level of oxygen of the coming to the fish water. If this level is below 6.0 ppm we have to increase the aeration in the water collection tank

- After the fish tank (outlet water), in order to see the consumption of oxygen. If the level is bellow 4.0 ppm we have to increase the aeration in the fish tank

- After the Bio-filter, in order to see if the oxygen is enough to keep the bacteria in healthy conditions and also to know what is the oxygen in the water that goes into the culture beds. If the level is bellow 5.0 ppm we have to increase the aeration in the bio-filter

- Outlet of the beds, in order to see the consumption of the plants. At this point we have to keep a minimum of 5.0 ppm and according to the pH we can increase the aeration in the beds

According to FAO [4] the level of Oxygen and pH in warm water fish and the Aquaponics part have to be Oxygen 4.0-6.0 ppm with pH in range of 6.0-8.5 for the fish and biger than 3.0 ppm Oxygen and 5.5-7.5 pH for the plants. By using the aeration as a controller of both Oxygen and pH we can adjust the levels according to the needs.

Temperature

As the target is the system to work under the natural environmental conditions not any temperature control system is required.

The water temperature is related the most to the needs and the new added water, as the system is shaded and the water is recirculating 24/7 there is no significand fluctuations. The proposed for the Tilapia cultivation water temperature is about 22-32°C and for the plants 18-30°C [4]. The measurement of the water temperature is recommended to be done with the oxygen-meter (usually most of the oxygen-meters have temperature sensor also)

Temperature

- Inlet water to the fish tank, to know the temperature that is coming into the fish tank

- Outlet of the beds, to check the efficiency of the shade and if the temperature is fluctuating a lot due to the weather temperature

- Min max air temperature, it is important to know (especially in tropic climates) the daily fluctuation of the temperature. By recording the min & max temperature useful data for the effect of the environmental conditions will be collected

From the table 2 it is obvious, for the specific conditions, the duration of the cultivation period, starting during the end f September and lasting until the early of June.

As per some early data, collected from the author, the environmental temperature has not any significant difference inside the net house compared to the common in region temperature profile. More Data and replication of measurements per year is needed according to the specific environmental temperature in order the farm to have the unique for the area temperature profile.

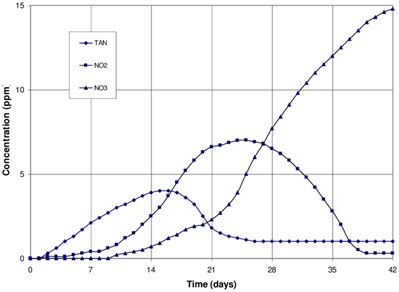

Nutrients

The waste of the fish after the decomposition through the bio-filtration procedure will provide to the plants the necessary for their growth nutrients. As the target is the creation of high levels of Nitrates (necessary and easy absorbed nutrients), enough to cover the needs of the crops, the biological filter is designed according to the maximum fish feed rate capable to transform the waste of the fish to useful nutrients for the plants. In the beginning of the season, during September the activation of the bio-filter is necessary to be done. A typical bio-filter activation needs up to forty days as the following figure 2 layout.

Instead of waiting up to forty days for the activation of the filter alive bacteria is proposed to be added to speed up the activation procedure. The expected levels of nutrients, as per some practical data that are collected from the author are presented in the following table 3.

|

Ammonia |

Nitrite |

Nitrate |

Nitrate in Beds |

|

|

Month |

(ppm) |

(ppm) |

(ppm) |

(ppm) |

|

September |

1.0-2.0 |

1.0-0.5 |

80-40 |

40 |

|

October |

0.5-1.0 |

0.8-0.4 |

60-40 |

30 |

|

November |

0.4-0.6 |

0.2-0.0 |

40-20 |

20 |

|

December |

0.4-0.6 |

0.2-0.0 |

<20 |

15 |

|

January |

0.4-0.6 |

0.2-0.0 |

<20 |

10 |

|

February |

0.4-0.6 |

0.2-0.0 |

<20 |

<10 |

|

March |

0.4-0.6 |

0.2-0.0 |

<20 |

<10 |

|

April |

0.4-0.6 |

0.2-0.0 |

<20 |

<10 |

By using alive bacteria from the beginning of the bio-filter’s activation a similar to the above table 3, decompose of the waste elements will be figured up. The first twenty days slide high levels of Ammonia and Nitrite will be observed and after thirty days almost all the produced nutrients will be absorbed from the plants lasting to zero values when the hydroponic part will be in full capacity. Gradually, as the plants are growing and the Bio-filter is working on its full capacity all the produced nutrients is absorbed almost to zero levels.

Aquaculture components

The aim of the Aquaculture component as a part of the Aquaponics system is to provide the necessary wastes which furthermore will transform to nutrients for the plants cultivation.

Fish and fish tank

For the proposed model Tilapia (Oreochromis niloticus) is chosen as the cultivated fish, depending on the specific needs the weather conditions the water characteristics and the experience of the related people, other species could also been used.

Tilapia is proposed because of

- Is well known fish species with a wide local market

- Is tolerant in a wide range of environmental conditions

- It has very low water exchange needs

- Has good growth under culture conditions

- There are available juveniles in the local market

- Good quality Fish feed is also available and in the market

The fish will be cultured in a tank of 5.0 m3 by using RAS technic, and then after wastes and waste water, will be used for the vegetables cultivation.

The fish tank could be any shape but circular tank is recommended as the most efficient from the self-cleaning point of you.

As per the study of James M. Ebeling & Michael B [9], Circular tanks are attractive for the following reasons:

- Simple to maintain

- Provide uniform water quality

- Allow operating over a wide range of rotational velocities to optimize fish health/condition

- Settle able solids can be rapidly flushed through the center drain

- Designs that allow for visual or automatic observation of waste feed to enable satiation feeding are possible [9]

The oxygen level in the fish tank have to be above 4.0 ppm, this can be successfully achieved by using up to four air diffusers about one meter long and diameter 12 mm.

The air will be supplied 24/7 from air blower of 08-1.0 kw and through the daily measurements into the fish tank will be done the adjustments. The inlet water will be done from the top of the tank and the outlet from the bottom in order to be removed as many as could be solid wastes to the next step, mechanical remover part in our case sedimentation tank. For the model a number of 300 fish are enough to cover the needs of the proposed aquaponics components as the following table 4 layout.

|

Biological Data |

|

|

Initial fish number |

300 |

|

Initial Av. weight (gm) |

0.05 |

|

Initial biomass (kg) |

15 |

|

Initial density (kg/m3) |

2.9 |

|

Survival (%) |

90 |

|

Final fish number |

270 |

|

Final Av. weight (gm) |

500 |

|

Final density (kg/m3) |

26.5 |

|

Production period (months) |

8.0-10 |

|

Final biomass (kg) |

135 |

Table 4: Aquaculture component and biological data of the system.

RAS as a part of aquaponics

RAS is chosen as the most efficient system for arid areas where the water is limited and the discharge of the wastes difficult. Recirculating Aquaculture Systems (RAS) have been developed to overcome pollution concerns and stocking capacity limits of conventional terrestrial aquaculture facilities. RAS offer several advantages over traditional flow-through systems including: 90-99% reduced water consumption [10]. The Aquaculture part should be controlled and monitored on daily basis as described above in order to ensure the productivity of the system and the viability of the fish and plants. Special care is needed in the beginning when the first fish will be stocked.

In order to avoid any rapid increased of the Ammonia and or Nitrites level it is recommended the following steps to be followed

- Stocking of the half fish biomass until the system is ready

- Add alive bacteria by following the suppliers instruction

- By controlling the daily feed rate keep the levels of ammonia less than 2.0 ppm

- Follow up the results of the daily measurements and add into the fish tank the rest of the fish when the Nitrite start be less than 0.5 ppm

- Start the replantation when the first Nitrate are appeared and increase the cultures of the plants gradually by following the increasing of the Nitrates.

For our RAS model the necessary details are as describing in the following table 5.

|

System Description |

||

|

Equipment |

Details |

Unit |

|

Tanks |

1 |

Nos |

|

Dimensions |

D:2.2 H:1.35 |

m |

|

Volume per tank |

5.1 |

m3 |

|

Total volume |

5.1 |

m3 |

|

Water usage vol/tank |

5.0 |

m3 |

|

Total usage vol/unit |

5.0 |

m3 |

|

Water recycling %/tank |

80% |

|

|

Water recycling (m3/tank |

4.0 |

m3 |

|

Turnover rate: |

75 |

minutes |

|

Total recycling water/unit |

4.0 |

m3/hour |

A feeding program has been followed according to the needs and the results of the fish body weight and biomass estimation. The maximum, daily fish feed quantity, during the whole period for the model is up to 1.0 kg/day. By using a fish feed with about 32% protein the estimated volume of the bio-filter, (by using bio-media with surface of 600 m2/m) is about 150 ltr. Three plastic containers of 1.0 m3 are necessary for the RAS. One to host the bio-media. Second will be used as sedimentation tank and the third as water collector after the vegetable culture beds. The fish biomass and the growth has to be evaluated every end of the month and the feeding program have to be rescheduled accordingly. The feeding needs to be done according to the needs by using good quality extruded floated pellets containing 32% protein. The daily feed rate and the feed consumption presented in the below table 6.

|

Feeding Rate |

Daily Feeding |

|

|

Month |

(% FR) |

(kg) |

|

Sep |

2.50% |

0.188 |

|

Oct |

2.10% |

0.548 |

|

Nov |

1.80% |

0.756 |

|

Dec |

1.40% |

0.973 |

|

Jan |

1.20% |

1.056 |

|

Feb |

1.00% |

1.037 |

|

Mar |

0.90% |

1.021 |

|

Apr |

0.80% |

1.08 |

The daily amount of fish feed is recommended to be split in two meals, the first about 10:00 and the second about to 14:00 in order the feeding to be take place during the maximum of Oxygen level. Six days a week with one starvation is a common practice and is recommended. The day after the starvation day is the most suitable for the necessary cleanings of the system or sampling of fish. It is essential at the beginning of the season to be count and weighed all the fish in order initial biomass to be estimated and accordingly the feeding program to be scheduled and applied in table 7.

|

Fish |

Av.Weig |

Biomass |

Density |

|

|

Month |

(Nos) |

(gm) |

(kg) |

(kg/m3) |

|

Sep |

150 |

50 |

7.5 |

1.5 |

|

Oct |

290 |

90 |

26.1 |

5.2 |

|

Nov |

280 |

150 |

42 |

8.4 |

|

Dec |

278 |

250 |

69.5 |

13.9 |

|

Jan |

275 |

320 |

88 |

17.6 |

|

Feb |

273 |

380 |

103.7 |

20.7 |

|

Mar |

270 |

420 |

113.4 |

22.7 |

|

Ap |

270 |

500 |

135 |

27 |

To be accurate, the related to the fish biomass data, every end of the month a sampling of about 20% of the total number of fish need to be counted and weighted for the average fish body weight estimation. The average weight will be used for the estimation of biomass and the feeding schedule for the next month. At the end of the season a final count and weighed of all the fish have to be conducted in order to find out the growth performance. By following the monthly sampling and the above given table 7, can be easily figure out if any problem is disturbed the welfare of the fish and the necessary adjustments can be provided. A total biomass of about 135 kg (27.0 kg/m3) had been produced in a period of 8 months in the proposed model. The FCR for Tilapia at these conditions was ranged from 1.3 to 1.6 in most of the farms where the model implemented.

VEGETABLES PRODUCTION DATA

|

Basil |

25-30 per m2 |

|

Lettuce |

25 per m2 |

|

Coriander |

20-25 per m2 |

|

Okra |

15-20 per m2 |

|

Parsley |

12-15 per m2 |

|

Mint |

12-15 per m2 |

|

Cucumber |

6-8 per m2 |

|

Tomato |

6-8 per m2 |

During the cultivation period in order to avoid disease incident whenever a plant seems to be affected have to be remove from the system. By following this procedure not any significant problem will be detect and not will eliminate the usage of pesticides. Periodically check of the roots is needed and washing of the roots (if start to look brown) it is recommended in order to be clean white and healthy. The air diffusers is very important to be placed on a way to provide a good mixing of water and slight movement of the roots. In the proposed beds about four pieces of air diffusers, 80 cm long 8 mm diameter, are enough to provide the necessary oxygen in the plants. The supply of the aeration (through the diffusers) must be controlled by separate valves and according to the levels of oxygen and pH one or four can be in operation. For example, when the oxygen is lower than 3.0 ppm more diffusers must working and when the pH is higher than 7.2 less etc.

WATER CONSUMPTION

The system is supported with the minimum of equipment also

- Water recirculation pump of 4.0 m3/hour

- Air blower 1.0 kw

|

Type of system |

Consumption of new water per kg fish produced per year |

Consumption of new water per cubic meter per hour |

Consumption of new water per day of total system water volume |

Degree of recirculation at system vol. recycled one time per hour |

|

Flow- through |

30 m3 |

1 712 m3/h |

1 028% |

0% |

|

RAS low level |

3 m3 |

171 m3/h |

103% |

95.90% |

|

RAS intensive |

1 m3 |

57 m3/h |

34% |

98.60% |

|

RAS super intensive |

0.3 m3 |

17 m3/h |

6% |

99.60% |

The system can run with multispecies of vegetables and Herbs but for understating purposes is presented a monoculture production as a sample for the productivity of the system. With the hypothesis that the system will run as monoculture is capable to produce per month as per the following table 10.

|

Production Data as Monoculture |

||||

|

Lettuce |

Cucumber |

Cor-Prsley- Mint |

||

|

Production per m2 |

(min) kg/m2 |

6.2 |

12 |

4 |

|

All farm (60 m2) |

(min) total kg/60 m2 |

372 |

720 |

240 |

The productivity refers to the real collected data and could be used as reference in case of similar units were monoculture will be applied.

RESULTS AND OBSERVATIONS

In the model, as per the above description, successfully have been produced, up to 135.0 kg (27.0 kg/m3) in a farm in Al Ain, Abu Dhabi. This model has the potentiality to maintain a continuously standard biomass of 150 kg (30 kg/m3) enough to cover the monthly needs of a family if a proper fish harvesting program have been scheduled. The production of vegetables was also satisfactory and some of the vegetables produced were sold on the local market to cover some of the costs. Lettuce is the most suitable for this system by giving production of 20-25 pcs/m2/month (6.2-7.0 kg/m2/month). Cucumber can be also produced in a satisfied amounts giving a production of 12-16 kg/m2. Coriander Parsley Basil and Mint are also suitable and the production as monoculture could extend up to 8.0-10 kg/m2/month. It is very important the seeds to be suitable for Aquaponics and is not recommended to be used the ones which are for open field cultures. Instructions from agronomists have to be followed in order to be chosen the most appropriate seeds. In case of use open field seeds some problems related to the roots will be faced and the productivity will be lower compared to the ones which is suitable for soilless Aquaponics.

DISCUSSION

CONCLUSION

The reason why, is coming from two sides. The appropriate design and the correct calculations of RAS that will support the system and the luck of cultivation knowledge. The luck of data collection system is also a big disadvantage in small farms. It is essential and highly recommended before any trial been done, advices to be taken from specialists in each field. It is also essential and is recommended to any prospective small or big scale farm the establishment of standard procedures and recording system. In the Appendix A are presented samples of spreadsheets which could be used for data recording. Targeting to a sustainable and integrate usage of the available fresh water, the concept of an aquaponics system which is utilizing the water on efficient way, seems to be the most suitable, affordable and profitable solution, for the arid areas of the region. The system could be characterized totally integrated and could be used as prototype to the existing or new, commercial Aquaculture farms by giving the potentiality of additional income from the vegetable cultures and better control of the available water.

REFERENCES

- Goddek S, Espinal CA, Delaide B, Jijakli MH, Schmautz Z, et al. (2016) Systems navigating towards decoupled aquaponic systems: A system dynamics design approach. MDPI 8: 303.

- Rakocy JE (2012) Aquaponics—integrating fish and plant culture. Wiley-Blackwell, New Jersey, USA. Pg no: 344-

- Rakocy JE (1989) Hydroponic lettuce production in a recirculating fish culture system. Island Perspectives, 5-10.

- FAO (2014) Small scale aquaponic food production. Integrated fish and plant farming. FAO, Rome, Italy.

- Review of Abu Dhabi Aquaculture Environmental Agency of Abu Dhabi (EAD) 2016.

- Rakocy JE (1989) Island Perspectives, Virgin Islands agricultural Experiment Station: Saint Croix, VI, USA, Pg no: 5-10.

- Hirich A and Choukr-Allah R (2017) Water and energy use efficiency of greenhouse and net house under desert conditions of uae: Agronomic and economic analysis. Springer Water, Berlin, Germany.

- Perschbacher PW, Stickney RR (2017) Tilapia in Intensive Co-culture. John Wiley & Sons, Ltd, Hoboken, New Jersey, United States.

- James M. Ebeling JM, Timmons MB, Hightower PG (2011) An Engineers Design and Construction Details For Several Classroom Aquaculture/Aquaponics Systems. DocPlayer, Germany.

- Bartelme RP, McLellan SL, Newton RJ (2017) Freshwater recirculating aquaculture system operations drive biofilter bacterial community shifts around a stable nitrifying consortium of ammonia-oxidizing archaea and comammox nitrospira. Front Microbiol 8: 101.

- Bregnballe J (2015) A Guide to Recirculation Aquaculture. FAO, Rome, Italy.

- Love DC, Fry JP, Genello L, Hill ES, Frederick JA, et al (2014) An International Survey of Aquaponics Practitioners. PLoS One 9:

APPENDIX A

Samples of records and spreadsheets for data collection.

|

CROPS HARVESTING RECORD |

||||

|

Date |

Number of Bed |

|

|

|

|

Specie |

Cucumber |

Lettuce |

Lettuce |

Tommato |

|

Starting Date |

|

|

|

|

|

Pcs |

|

|

|

|

|

01-Jan |

|

|

|

|

|

02-Jan |

|

|

|

|

|

03-Jan |

|

|

|

|

|

04-Jan |

|

|

|

|

|

05-Jan |

|

|

|

|

|

06-Jan |

|

|

|

|

|

07-Jan |

|

|

|

|

|

08-Jan |

|

|

|

|

|

09-Jan |

|

|

|

|

|

10-Jan |

|

|

|

|

|

11-Jan |

|

|

|

|

|

12-Jan |

|

|

|

|

|

13-Jan |

|

|

|

|

|

14-Jan |

|

|

|

|

|

15-Jan |

|

|

|

|

|

FISH MONITORING RECORD |

|

|

|

|

|

|||

|

Date |

Type of food |

Kg of food |

Mortality |

New Water |

Oxygen |

pH |

Temperatur |

Observations |

|

01-Nov |

|

|

|

|

|

|

|

|

|

02-Nov |

|

|

|

|

|

|

|

|

|

03-Nov |

|

|

|

|

|

|

|

|

|

04-Nov |

|

|

|

|

|

|

|

|

|

05-Nov |

|

|

|

|

|

|

|

|

|

06-Nov |

|

|

|

|

|

|

|

|

|

07-Nov |

|

|

|

|

|

|

|

|

|

08-Nov |

|

|

|

|

|

|

|

|

|

09-Nov |

|

|

|

|

|

|

|

|

|

10-Nov |

|

|

|

|

|

|

|

|

|

11-Nov |

|

|

|

|

|

|

|

|

|

12-Nov |

|

|

|

|

|

|

|

|

|

13-Nov |

|

|

|

|

|

|

|

|

|

14-Nov |

|

|

|

|

|

|

|

|

|

15-Nov |

|

|

|

|

|

|

|

|

|

Daily Measurements Record |

||||||||||||||||||

|

Date |

Oxygen |

Ammonia |

Nitrite |

Nitrate |

Temperature |

pH |

||||||||||||

|

Before |

After |

Outlet of |

Before |

After |

Outlet of bed |

Before |

After |

Outlet of bed |

Before |

After BF |

Outlet of bed |

Before |

After |

Outlet of bed |

Before |

After |

Outlet of bed |

|

|

1-Jan |

||||||||||||||||||

|

2-Jan |

||||||||||||||||||

|

3-Jan |

||||||||||||||||||

|

4-Jan |

||||||||||||||||||

|

5-Jan |

||||||||||||||||||

|

6-Jan |

||||||||||||||||||

|

7-Jan |

||||||||||||||||||

|

8-Jan |

||||||||||||||||||

|

9-Jan |

||||||||||||||||||

|

10-Jan |

||||||||||||||||||

|

11-Jan |

||||||||||||||||||

|

12-Jan |

||||||||||||||||||

|

13-Jan |

||||||||||||||||||

|

14-Jan |

||||||||||||||||||

|

15-Jan |

||||||||||||||||||

Citation: Lampakis E (2019) Small Scale Fresh Water Aquaponics as Solution in Deserted and Arid Areas. J Aquac Fisheries 3: 020.

Copyright: © 2019 Efstathios Lampakis, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.