Active Polymeric Packaging: Innovation in Food with Potential Use of Sustainable Raw Material

*Corresponding Author(s):

Marcia Regina De MouraGroup Of Hybrid Composites And Nanocomposites, Department Of Physics And Chemistry, FEIS-UNESP, Ilha Solteira, Brazil

Email:marcia.aouada@unesp.br

Abstract

The preparation of polymeric films for use as packaging is something that has been gaining prominence in recent years. In order to enhance the properties of natural polymers, researchers have used additives that are incorporated into film-forming solutions such as nano particles and essential oils. In this review we are discussing a little about the use of different polymers and some of these additives, showing the importance of use and some applications in the packaging area. The whole discussion was guided by the growing current concern of consumers with food safety, which leads the packaging industry to propose new materials that are safer and more active against the proliferation of microorganisms that may harm human health. The potential use of natural products and waste is also highlighted in the review, due to the environmental importance this brings to the research sector.

Keywords

Active packaging; Biopolymers; Essential oils; Food packaging

Introduction

The packaging is used to contain food and to protect them against humidity, light, temperature, microorganisms and oxidation [1]. Currently, most of the polymers in conventional packaging are obtained from non-renewable resources, like petroleum, generating a series of accumulation of residues [2]. Considering the environmental issues and consumer demand for biodegradable packaging, the natural polymers have received a great attention to form active films [3-6].

Moreover, the incorporation of many essential oils, in the film formulation improves antioxidant and microbiological properties and this can increase the shelf life of the food [7], like carvacrol, eugenol, d-limonene and peppermint oil [8,9]. Up to now, several natural polymers and essential oils have been studied in various types of food.

Active packaging acts as a barrier to external detrimental factors and has an active role in food preservation, maintaining or prolonging his shelf-life. There is a diversity of active packaging systems that comprise additives which release properties, absorption, removal and control of microbial and quality. Besides this, several studies are interested in the properties of essential oils and their actives such as antioxidants, polyphenols and tocopherols [1,10,11].

Therefore, this review presents an overview of the existing studies about films based on natural polymers and essential oils. In the and are discussed the applications and the existing commercial films are presented.

Food Packaging

The first packaging came in 3000 BC, a time when Egyptians used pottery and glass only to contain and store food [12]. With advances in global trends and consumer preferences, new materials such as metals and plastics have been introduced in the industry and traditional packaging has had four basic functions (Figure 1) [13,14]:

- Containment: It is the most basic function, facilitating transportation and handling.

- Protection: Is considered the main function, as it keeps the products in a limited volume, avoiding leaks and breaks; also protects against biological influences (microorganisms, insects, and rodents), physical (mechanical damage, shock and vibration) and chemical (gases, moisture and light) influences.

- Convenience: Meets the demand of consumers with different lifestyles, facilitating the preparation and allowing them to enjoy the food the way they want; is the case of packages with fractionated portions, oven safe trays and bags for boiling.

- Communication: In addition to identifying the food, providing information about its nutritional content and how it is prepared, is also allied to product marketing.

Figure 1: Basic functions of traditional food packaging.

Figure 1: Basic functions of traditional food packaging.

To meet all these functions, the packaging is divided into three levels: primary, secondary and tertiary. Primary packaging or sales packaging (cardboard boxes for pizzas, plastic bags for bread, aluminum cans for soft drinks) are those that are in direct contact with the food. Often, it is just the main package that the consumer buys and, depending on the product, may have one or more layers. Secondary packages or grouped packages (boxes, corrugated boxes) contain several main packages and are designed to distribute and display the product. In this case, they are called ready for the shelf. Finally, tertiary packaging or transit packages (wooden pallets) group the secondary packagings, facilitating loading and unloading [15,16].

Among the four basic food packaging materials (paper, plastic, glass and metal), plastics, such as polyolefins and polyesters, are the most widely used because of their optical properties, low cost, flexibility, high strength and durability [13].

Global plastics production has increased tenfold since the 1960s, arriving at 322 million tonnes in 2015 [17]. Approximately 42% of this production is destined for the packaging sector, and almost half of this amount is used in food packaging [18,19].

Although these materials have certain advantages, they cause serious environmental impacts because they are petroleum-based and are not easily degraded after their entire life cycle (raw material selection, production, analysis of interaction with food, use and disposal) [19,20]. In Europe alone, about 25.8 million tonnes of plastic waste is generated each year, and less than 30% of that waste is collected for recycling [17].

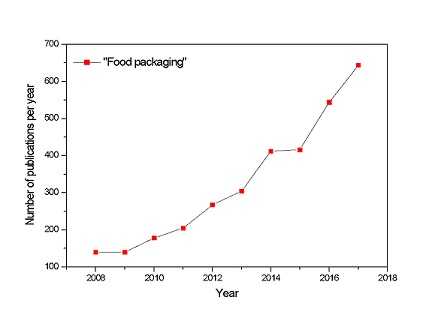

Figure 2 illustrates a bibliographic search from 2008 to 2017 in ISI's Web of Science database, using the term "Food Packaging" in "topics". As can be observed, research involving the area of food packaging has increased significantly in recent years, jumping from 140 publications in the year 2008 to 644 in 2017.

Figure 2: Graphic referring to the number of publications per year involving "Food Packaging" from 2008 to 2017.

Figure 2: Graphic referring to the number of publications per year involving "Food Packaging" from 2008 to 2017.

In view of the above, it is of the utmost importance to develop biodegradable packaging that can be used safely in food products. Biopolymers are being used for this purpose because they come from renewable sources and are recognized as safe by the Food and Drug Administration (FDA) [21-24].

The global market for biodegradable plastics accounts for less than 1% of the global plastics market, but growth is expected to increase gradually over the next few years. The growth of the market is driven by continuous activities in the research, development, daily search of the consumer and the need for greater environmental awareness. In this way biodegradable polymers have found their ultimate use in a variety of commercial applications. Disposable packaging and household appliances are expected to drive the biodegradable market [25].

Different methods are being employed to improve the characteristics and properties of biomaterials, especially by improving the water and gas barrier properties. Some of the improvements are in the addition of nanoparticles, diversification of essential oils, mixing with other components, addition of cellulose, chemical / physical modification, etc., either in packaging or coatings showing its wide area of application in food packaging.

Active packaging is a promising future in the packaging market, either with the ability to slowly release functional additives on the surface of food, with antioxidant, antimicrobial role, extending the shelf life of products, storage of oils, the use of biodegradable packaging in the treatment of food spoilage is also of great importance [26].

Some studies being conducted determine that some active films may act as carriers of a wide range of food additives including vitamins, antioxidants, minerals, dyes, flavors, and antimicrobial compounds. However, it is necessary to develop better research and practical tests to meet the needs of consumers and help in the replacement of conventional packaging [21].

Biopolymers

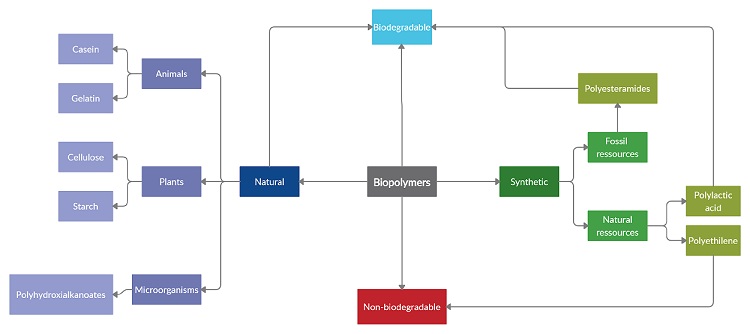

Biopolymers are a class of polymers that are produced by living matter (Figure 3). They are being studied with great interest over the past few years due to the concern of the overuse of plastic and petroleum derived materials and its non-biodegradable characteristics. It is important, however, to notice that biopolymer and biodegradable are not interchangeable concepts. Biodegradable is a material that, when exposed to microorganisms, water, methane and carbon dioxide, suffers complete degradation and deterioration [27], while the definition of biopolymers was described above.

Figure 3: Flowchart of natural and synthetic biopolymers and their characteristics regarding biodegradability

Recently, biopolymers are being studied to be used in food packaging. This necessity comes from the realization that it’s unsustainable to maintain the use of plastics for this purpose, due to the non-biodegradable nature of plastics and other petroleum-based materials.

There are a few things that need to be taken into consideration if we need to replace plastic with biopolymers, to some extent. Its mechanical properties, water vapor barrier and oxygen barrier are all important properties to analyze before producing the food packaging. Most biopolymers have poor mechanical properties and water vapor barrier and in order to achieve the material with the physicochemical characteristics desired, it is necessary the use of composites, for example [28].

Once the physicochemical properties match those of the desired regulations, it’s possible to look further. The characteristics of biopolymers and its use in packaging gives it the ability and versatility of being modified to be given new and desirable attributes like anti-microbial, antioxidant and anti bactericidal effect [29].

Chitosan, Bacterial Cellulose (BC) and starch are a few biopolymers that are being studied and used for food packaging, with all of these having the possibility of being modified for better characteristics. Chitosan, for example, is a polysaccharide, derivative of the deacetylation of chitin, that can be used purely or modified. The addition of plasticizers, like glycerol, can improve the mechanical properties of the film, making it possible to extend shelf life and protect the product from damage like enzymatic browning in fruits, for instance. On the other hand, it is shown in WANG et al. [30], that it’s possible to add beeswax and propolis, for example, to produce active food packaging, with antimicrobial properties.

Bacterial cellulose is a form of cellulose, produced from microorganisms, primarily from the Acetobacter xylinum bacteria. Both bacterial cellulose and plant cellulose have the same chemical composition, but it is important to highlight that the similarities stop there. Bacterial cellulose is purer, has higher Young’s modulus, higher water uptake and it’s nanostructured, while its plant counterpart is microstructured [31]. Given these characteristics and its ability to form composites, BC is being studied for food packaging, among other applications. BC is edible, non-toxic and its mechanical properties makes it a great starting point for food packaging and edible food packaging. The aim in food packaging is the same as mentioned above as used in chitosan films, while edible BC packaging can also enhance the nutritional value of the product [32].

Edible packaging, films and coatings consists of a concept where, besides protection of the product, the packaging can also be ingested. There are many studies surrounding this subject, especially because the modern consumer is demanding a more natural, sustainable food package. Edible films and coatings are often used as interchangeable concepts but are applied differently. While films are solid laminates that are later applied to cover the product, coatings are ofter applied by immersion or spraying, requiring it to be used as a liquid and to be dried when it’s already applied to the product [33].

A few examples of edible food packaging can be cited. For instance, Puscaselu et al. [34], studied the possibility of an edible film enriched with Stevia rebaudiana, a sweetener, capable of being used as a food packaging for instant drinks, like coffee or cappuccino. The intention would be for the packaging to be soluble and to be used as the sweetener once the beverage is made. The results found are promising for the substitution of normal packaging. Other materials utilized in the studies of new edible coatings and films are polysaccharides, fruit-purees, lipids and proteins.

Pectin (P) and Nano Chitosan (NSC) films were studied by NGO et al. [35]. The results showed that the P: NSC mixture in a 50: 50 ratio is promising. The values of oxygen permeability and the oxygen transmission rate were low, since the interaction of these substances formed compact films, thus they are good oxygen barriers in comparison with low density polyethylene and high density polyethylene, since oxygen is a important factor that causes oxidation, initiating several changes in the foods that affect the useful life of the fruits. Chitosan nanoparticles exhibit potent bactericidal activity, inhibited the growth of Colletotrichum gloeosporioides, Saccharomyces cerevisiae, Aspergillus niger and Escherichia coli, however they do not show cytotoxicity in mammalian cells [35].

According to Priyadarshi, Kim and Rhim [36], calcium ion crosslinked alginate films incorporated in sulfur nanoparticles, the concentration of 2 % by weight, increased the hydrophobicity of the film. The color of the film's surface has changed significantly, with a decrease in transparency. Thus, the film showed excellent UV barrier properties with increased concentration of sulfur nanoparticles. As for thermal stability, the results indicated that there is no effect due to the incorporation of nanoparticles. As for the antimicrobial activity against food-borne pathogenic bacteria, the composite film did not completely destroy E. coli, but showed bacteriostatic activity that reduced 60 % of bacterial colonies. However, the activity against L. monocytogenes was considered highly bactericidal in the highest concentration of nanoparticles. Thus, the nanocomposite film can be used for packaging frozen foods with a high moisture content.

Roy and Rhim [37], developed alginate-based films with insertion of copper sulfide nanoparticles. The pure alginate film is flexible and has shown high light transmission for UV and visible lights. The light transmittance of the alginate-based film decreased in all wavelength bands by the addition of copper sulfide nanoparticles. The alginate-based films showed stages of thermal decomposition patterns in two stages, and the addition of nanoparticles did not significantly influence the thermal stability of the alginate film. The nanocomposite showed potent antibacterial activity against Gram-negative bacteria (such as E. coli), but showed a slight drop in the growth rate of Gram-positive bacteria (L. monocytogenes). Nanocomposite films with significantly improved physical and functional properties have a high potential for active food packaging applications.

LI et al. [38], isolated Cellulose Nanocrystals (CNC), by alkaline treatment, bleaching and hydrolysis with sulfuric acid, of pea husk and evaluated their reinforcement capacity for Carboxymethylcellulose (CMC) films. The obtained CNC showed needle-like shapes. The pure CMC film showed the highest light transmittance against visible and UV light, suggesting the greater transparency and lower UV barrier property of the CMC film. The incorporation of CNC increased the stiffness of the composite film, however it limits the movement of the molecular chains of the CMC and, thus, reduces the elongation at break. The nanocrystals decreased the water vapor permeability for composite film by 53.4 % with 5 % by weight of CNC reinforcement. The composite film maintained the highest vitamin C content throughout the storage of the analyzed fruit, demonstrating the greatest gas barrier of the composite film. These results indicated that the nanocomposite may have a promising application potential as a packaging material for edible foods.

Alizadeh-Sani, Mohammadian and Mcclements [39], inserted cellulose nanofibers (for mechanical strength), essential oils (2% rosemary oil) and TiO2 nanoparticles (1%) into a whey protein matrix. Cellulose nanofibers were responsible for mechanical resistance, essential oil and TiO2 for antimicrobial and antioxidant activity. The incorporation of rosemary oil and TiO2 in the composite films significantly improved the color stability of the lamb meat samples compared to the controls. Active packaging significantly reduced microbial growth, lipid oxidation and lipolysis of meat, thus extending the useful life of lamb meat, from about 6 to 15 days, during refrigerated storage. Microbiological and physical-chemical tests correlated strongly with the sensory evaluation of meat quality attributes during storage.

Essential Oils

Systems with mixing, dispersion or suspension of two or more immiscible liquids are known as emulsions in which one of the liquids is dispersed in the other as small droplets (0.1-100 µm). Normally, emulsions are given among oil-in-water (O/W) or water-in-oil (W/O) mixtures. Nanoemulsion contain dispersed droplet sizes in the 6100 nm range, while emulsions typically form droplet sizes in the 0.1-100 µm range.

By inducing mechanical shear to the mixture either using a homogenizer can be formed an emulsion, a valve (high pressure) homogenizer or through sparging, with the purpose to create small droplets of a dispersed liquid one within the other. In the presence of an emulsifier, emulsions can be formed, which comprises both hydrophobic and hydrophilic components that become integrated at the water–oil or oil–water interface to reduce interfacial tension.

Emulsions are thermodynamically unstable (metastable) due the high free positive energy (interfacial tension) between the two phases. On the other hand, the smaller size of the dispersed droplets and the bigger density and viscosity of the continuous phase, will increase the kinetic stability of the emulsion.

There are two main groups of emulsions, single and multiple emulsions. They are differentiated by your different systems phases. Examples of single emulsions formed by O/W are milk, yogurt, creams, salad dressings, mayonnaise, ice cream and soups, to W/O case an example is the butter.

Multiple emulsions are more complex than single emulsions. The most found kind of multiple emulsions are water/oil/water (W/O/W) and oil/water/oil (O/W/O).

Essential oils are aromatic compounds isolated from vegetable materials, by some physical process, dispensation odor and other characteristics of this plant which are extracted, due their high volatility and complex composition. Also, these oils have their own potential antimicrobial and antifungal effects, that turn them broadly used in the pharmaceutical, food, agricultural and cosmetic industry. Recently, the essential oil has been approved by the US Food and Drug Administration department as a food additive [40].

Currently many studies are being developed on the application of these essential oils into polymeric matrices, in order to evaluate their properties into matrices, as well as the potential effects of the phenolic compounds on the inhibition of food borne pathogens. Therefore, follow below some studies that evaluated these questions [7,41].

The basil essential oil is widely used in the cosmetics and food industry as a flavoring agent, it is extract from the sweet basil, and it can crop and grow around the world. This essential oil contains more than 30 compounds, where the major chemical compounds are the monoterpenes and phenylpropanoids, though these compositions can diversify according to origin of the plants, maturity stage, growing season, nutrient availability and colours of flower. Wan et al. [42], found that this oil exhibit antimicrobial effect against different bacteria such as Escherichia coli, Enterobacter Enterobacter aerogenes, Enterobacter agglomerans, Listeria innocua, Listeria monocytogenes and Salmonella typhimurium.

Lately, the potential uses of basil essential oil as antimicrobial and antioxidant agents incorporated in a food packaging have been investigated. Bonilla et al. [43] and Perdones Montero et al. [44], prepared films by incorporation of basil essential oil into chitosan matrices, and Tongnuanchan et al. [45], by incorporation of this same essential oil, however into a fish skin gelatin matrix. All of them conclude a good film formation and high potential for food packaging application.

The bergamot essential oil is extracted from Citrus Bergamia, its major chemical compounds are limonene and linalool, and there are volatile materials. It has been found that the major efficiency of this oil is against Campylobacter jejuni, Escherichia coli O157, Listeria monocytogenes, Bacillus cereus, Staphylococcus aureus, Arcobacter butzleri and Penicillium digitatum.

Sanchez-Gonzalez et al. [46], work with a chitosan matrix incorporated with a Bergamot essential oil, in her study was observed an inhibition against the Penicillium italicum, showing a higher preservation compared to the other matrices. The same author, but in 2011 and works with a coating to fresh fruits, also incorporated bergamot essential oil in chitosan and hydroxypropyl methyl cellulose matrix, likewise performance the improvement of the final appearance of the fruit, as well as higher antimicrobial activity.

The clove essential oil has as a predominantly compound the eugenol, which is the main source of the antimicrobial and antioxidant activity. This oil is extracted from the buds and leaves of the Syzygium aromaticum tree. Some authors reported significant reductions of E. Coli and S. aureus treated with clove essential oil.

Pranoto et al. [47], incorporated garlic oil in edible films of the alginate after observing that oil inhibited growth of the bacteria Escherichia coli, Salmonella typhimurium, Staphylococcus aureus and Bacillus cereus. However, the authors observed that in more garlic oil concentrations (>0.2%), increase antimicrobial effect against Staphylococcus aureus and Bacillus cereus.

Gómez-Estaca et al. [6], produced gelatin based edible films containing or not chitosan and incorporated oregano essential oil and tested the effect when used for pack cold-smoked sardine. The stability of the fish was improved when they were packed with gelatin based edible films, and the films they had EOs were able slow lipid oxidation.

Produced films containing starch-gellan and thyme essential oil have antifungal properties against two microorganisms: Alternaria alternata and Botryotinia fuckeliana. This effect is attributed to the presence of thymol. The thymol is a monoterpene hydrocarbon and is the substance pharmacologically active, shown the cause damage to the cytoplasmic membrane of some microorganisms due to capacity that this compound has to make bonds through its hydroxyls with the amine and hydroxylamine groups of proteins present in the membranes of the microorganisms, altering the permeability of these membranes, which results in release of the content of your cells.

Riquelme et al. [48], studied the lemongrass essential oil antimicrobial activity when added in alginate films. The authors used different droplet size oil and tested the influence of the film's storage conditions in the physical and microbial properties. In the present work, it was possible to conclude the minor microbial growth happened in film storage at 11% RH and 20°C for E.Coli and 75% and 11% RH at 4°C for B. Cinerea microorganism.

Wang et al. [30], verified the potential of ginger as an antimicrobial agent. In this study, the authors added ginger and cinnamon oil in chitosan matrices and found a decrease in the count of microorganisms in pork when compared to pure chitosan films. They also found that in higher concentrations of oil in the matrix, the count of microorganisms was lower. The antimicrobial action of ginger is mainly due to the presence of chemical agents limonene and zingiberene.

López [49], works with addition of the black pepper essential oil into a gelatin polymeric matrix, besides to provide flavor, aroma and color, the use of this oil is appropriate as a natural food additive, with great potential antimicrobial against E. coli and S. aureus. In general, just the use of the black pepper essential oil already mean a gain in the antimicrobial and antioxidant activity [8], however the hydrophobicity of the oil and the elevated rate of volatiles, guide the studies for a way to provide more stability of these materials, therefore improving and preserving their characteristics.

Active Films for Packaging

The role of packaging today goes much further than just offering product protection. They are seen as strategies for consumer goods and ceased to be part, to be the product. Innovative packaging helps to gain space at points of sale, raising the value of the merchandise and consequently its profitability [50]. In general, they are developed to meet a particular product, and stores it and so maintain its quality longer. In this sense, a new category of packaging has been gaining ground in the market, bringing together innovative approaches to the conservation and enhancement of the shelf life of food and active packaging [1,51].

The first citation referring to the terms active packaging and smart packaging was made in Regulation 2004/1935 / EC of the European Parliament and of the Council, which states that: “all substances incorporated into foodstuffs coming from packaging must meet the criteria set out in Directive 89 / 107 / EC on food additives” [49,52].

Additives are classified according to Guideline 89/107 / EC in different categories and according to their effects on foods which are, flavorings (natural extracts as essential oils and their components), colorants, preservatives, and heat stabilizers [53]. Among the additive categories and aromas, especially essential oils and their constituents, has been a subject of great importance to researchers and has attracted the attention of packaging manufacturers because it is considered a safe method by the US Food and Drug Administration to prevent or delay the microbial deterioration of food [49].

The packages containing active films consist of a system based on the controlled release of an active compound in order to prevent or retard the growth of microorganisms on the outside of the food which, that is, responsible for their degradation, thus preserving food sensory properties. The release of these active compounds has two different mechanisms of action [54,55]. The first mechanism it consists immobilize the active compound in the polymer matrix by covalence so that it acts immediately when the food is placed in contact with the film. In a second mechanism the active compound is incorporated into the matrix in the dry state, so that when the film is placed in contact with a moist food, the compound is released, acting directly on the food [54,56].

The final film applied to the active packaging must have characteristics which are considered important for its application as to have good adhesion to the substrate and, valid for direct contact with food (adhesion depends mainly on the compatibility between the substrate and the coating polymers); the antioxidant activity should be efficient, for which the release of the agent should be adjusted so as to provide such characteristic; the final active coated structure must meet the functional packaging requirements of food products [6,57].

Antimicrobial activity

One of the most important causes of deterioration to feed is the growth of microorganisms in food. The reactions caused by the presence of these microorganisms end up accelerating lipid oxidation and other oxidation processes, producing changes in the organoleptic properties of foods [11,58].

An alternative to minimize such deterioration actions, and which has been the subject of studies, is the use of active antimicrobial packaging. By the release of volatile and non-volatile antimicrobial agents that can be incorporated into the polymer matrix, or through antimicrobial adsorption on polymer surfaces, the deterioration actions can be reduced and thus losses can be reduced by increasing the shelf life of food products [8,59].

Several compounds have been proposed to act as antimicrobial agents in food packaging, among them, the essential oils (EOs) that can be extracted from plants and spices and have strong properties that actively act against food-borne pathogens [26,49]. These actions are possible due to high concentrations of phenolic compounds such as flavonoids and terpenoids, which are part of the structure of these substances and which have been recognized by researchers as powerful antimicrobial agents [60-62].

The essential oils act by several distinct mechanisms, affecting the microbial cells in different ways. They can promote the disturbance of enzyme systems, in which it causes the compromising of the genetic material of the bacteria, through the attack of the phospholipid bilayer of the cellular membrane [11,63].

The antimicrobial activity of the additives incorporated in the polymer network depends not only on their effective activity but also on the characteristics of the matrix being used in the edible film. Therefore, these additives end up causing changes on some structural, physical and bioactive properties of the film, which can cause a shift in its properties, such as weakening of the mechanical properties, reduction of water permeability and increase in opacity. Therefore, it is necessary to optimize the efficacy of these bioactive agents incorporated in different matrices so that it can study effectively the potential of these additives [11].

Antioxidant activity

Antioxidant according to the National Agency of Surveillance (ANVISA), is a substance capable of delaying the appearance of oxidative alteration in several products as well as the rancification in foods. They block the oxidation process by neutralizing the harmful effects of free radicals. From the chemical point of view, antioxidants are aromatic compounds that contain at least one hydroxyl and may be synthetic or natural.

For a long time, synthetic antioxidants have been great allies in the food industry by they have powerful characteristics against microbial deterioration and loss of intrinsic quality of the product, resulting in a longer shelf life. However, its use in food has been the subject of questions based on the potential risks that such substances can cause to health [6,64]. In the last 20 years, researchers have focused on the study of natural antioxidants, such as tocopherol, plant extracts and essential oils from herbs and spices, as a way of replacing synthetic antioxidants with the aim of minimizing the harmful effects caused by such products substances [6,65].

In the polymer industry, such additives are usually applied as a way to avoid thermal degradation of the polymers during processing. By this, many studies have been done regarding in incorporation of antioxidants in different biopolymer films and coating, in order to investigate how they affect the functional properties of these compounds and how they act in food protection [6].

In general, the antioxidative action occurs through two different mechanisms, being classified as primary and secondary antioxidants. Are classified as primary, those antioxidants that by inactivation of free radicals through the donation of hydrogen atoms, or electrons, inhibit oxidation by transforming the radicals into stable substances. Secondary antioxidants have a greater diversity of modes of action than the primary ones, they can act with valence change (metallic ion bonding); inactivation of Reactive Oxygen Species (ERO), conversion of hydroperoxides to non-radical species or absorption of UV radiation [66-68].

In the active packaging, antioxidants act in two different ways in the first and simpler the method is called independent devices, which function as a kind of sachet, where the agent is stored separately from the food product and released at a given moment. In the second, the active agent is incorporated directly into the walls of the package, exerting an absorbent action of undesirable compounds of the free space or releasing antioxidant compounds [59,67,68].

The use of antioxidant agents in films indeed reduces the presence of reactive oxygen species that act as initiators of the oxidation process, but the studies on these additives should be optimized, considering that the antioxidants end up interfering in different ways in each product.

The diversification of biopolymers and essential oils are already in the market, and adding more value in determining potential use in the development of research. In addition, it can be stated that the main market for bioplastics today is products with lower shelf life, such as fresh fruits and vegetables and high shelf life products, such as frozen ones [69].

However, an obstacle is identified in the economic viability of bioplastics, and also in contrast to conventional packaging, as there are other disadvantages that limit its use in the present time exposure of these materials to the market and to the worldwide use of biodegradable and edible packaging materials, and therefore real applications are still limited to research and development only for interest groups [19,70].

Conclusion

Packaging is an essential and responsible item to guarantee the product's food safety during marketing, storage and to serve a certain product while maintaining its quality for a longer time. The food industry is labeled as an environmental polluting source and raises social concerns due to the non-biodegradability of plastic packaging of fossil origin and the insufficiency of the waste management system. Therefore, bio-based and biodegradable materials are promising alternatives to conventional plastics due to their availability, non-toxicity and biodegradability. Edible packaging, films and coatings consist of a concept where, in addition to protecting the product, the packaging can also be ingested. Active biodegradable packaging is required to replace petroleum-based plastics. Smart packaging acts as a barrier to harmful external factors and plays an active role in preserving food, maintaining or extending its useful life. Most biopolymers have poor mechanical properties and a water vapor barrier and to obtain the material with the desired physico-chemical characteristics it is necessary to use composites. Nanotechnologies certainly represent a promising complementary tool to further improve the mechanical and barrier properties of films and to add other functionalities, such as antimicrobial and antioxidant action. Many foods are susceptible to microbial attack during storage and therefore require adequate protection. One approach to protection is the development of antibacterial packaging that incorporates antibacterial agents into the packaging system. Consumer demands for safe and natural agents have led to the search for materials with adequate resistance to microbial growth, while maintaining the organoleptic properties of foods. Essential oils extracted from plants are a good choice with good antimicrobial activity. Although the food applications of essential oil have been successful, its loss due to its volatile nature needs to be considered. Studies on the controlled release of active ingredients are of paramount importance. The packages containing active films consist of a system based on the controlled release of an active compound in order to prevent or delay the growth of microorganisms outside the food, that is, responsible for its degradation, thus preserving the sensory properties of the food. Finally, the aspect of biodegradability remains largely missing. Biopolymer and biodegradable are not interchangeable concepts. In fact, compounds that inhibit the microbial deterioration of food can also have negative effects on the composting process.

Acknowledgement

FAPESP (Proc. 2013/07296-2 e Proc. 2019/06170-1), CAPES (001) e CNPq (PQ 312530/2018-8 e PQ 312414/2018-8).

Declaration of Conflicts of Interest

The authors declare no conflict of interest. The founding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- Ribeiro-Santos R, Andrade M, de Melo NR, Sanches-Silva A (2017) Use of essential oils in active food packaging: Recent advances and future trends. Trends in Food Science & Technology 61: 132-140.

- Feng J, Chen Q, Wu X, Jafari SM, McClements DJ (2018) Formulation of oil-in-water emulsions for pesticide applications: Impact of surfactant type and concentration on physical stability. Environmental Science and Pollution Research 25: 21742-21751.

- Mohajer S, Rezaei M, Hosseini SF (2017) Physico-chemical and microstructural properties of fish gelatin/agar bio-based blend films. Carbohydrate Polymers 157: 784-793.

- Sahraee S, Milani JM, Ghanbarzadeh B, Hamishehkar H (2017) Physicochemical and antifungal properties of bio-nanocomposite film based on gelatin-chitin nanoparticles. International Journal of Biological Macromolecules 97: 373-381.

- Kurek M, Galus S, Debeaufort F (2014) Surface, mechanical and barrier properties of bio-based composite films based on chitosan and whey protein. Food Packaging and Shelf Life 1: 56-67.

- Gómez-Estaca J, López-de-Dicastillo C, Hernández-Muñoz P, Catalá R, Gavara R (2014) Advances in antioxidant active food packaging. Trends in Food Science & Technology 35: 42-51.

- Nunes JC, Melo PTS, Lorevice MV, Aouada FA, de Moura MR (2021) Effect of green tea extract on gelatin-based films incorporated with lemon essential oil. Journal of Food Science and Technology 58: 1-8.

- Zhang H, Hortal M, Dobon A, Bermudez JM, Lara-Lledo M (2015) The effect of active packaging on minimizing food losses: Life Cycle Assessment (LCA) of essential oil component-enabled packaging for fresh beef. Packaging Technology and Science 28: 761-774.

- Donsì F, Annunziata M, Vincensi M, Ferrari G (2012) Design of nanoemulsion-based delivery systems of natural antimicrobials: Effect of the emulsifier. Journal of Biotechnology 159: 342-350.

- Alfonzo A, Martorana A, Guarrasi V, Barbera M, Gaglio R (2017) Effect of the lemon essential oils on the safety and sensory quality of salted sardines (Sardina pilchardus Walbaum 1792). Food Control 73: 1265-1274.

- Atarés L, Chiralt A (2016) Essential oils as additives in biodegradable films and coatings for active food packaging. Trends in Food Science & Technology 48: 51-62.

- Trinetta V (2018) OBSOLETE: Definition and function of food packaging. Reference Module in Food Science.

- Marsh K, Bugusu B (2007) Food packaging-roles, materials, and environmental issues. Food Science 72: 39-55.

- Vanderroost M, Ragaert P, Devlieghereac F, De Meulenaer B (2014) Intelligent food packaging: The next generation. Trends in Food Science & Technology 39: 47-62.

- Dixon-Hardy DW, Curran BA (2009) Types of packaging waste from secondary sources (supermarkets)-The situation in the UK. Waste Management 29: 1198-1207.

- European Parliament and Council (2018) European Parliament and Council Directive 94/62/EC of 20 December 1994 on packaging and packaging waste.

- European Commission (2018) Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions - A European Strategy for Plastics in a Circular Economy.

- Geueke B, Groh K, Muncke J (2018) Food packaging in the circular economy: Overview of chemical safety aspects for commonly used materials. Journal of Cleaner Production 193: 491-505.

- Rhim J, Park H, Ha CS (2013) Bio-nanocomposites for food packaging applications. Progress in Polymer Science 38: 1629-1652.

- Silvestre C, Duraccio D, Cimmino S (2011) Food packaging based on polymer nanomaterials. Progress in Polymer Science 36: 1766-1782.

- Azeredo HMC, Rosa MF, Mattoso LHC (2017) Nanocellulose in bio-based food packaging applications. Industrial Crops and Products 97: 664-671.

- Missio AL, Mattos BD, Ferreira DF, Magalhães WLE, Bertuol DA, et al. (2018) Nanocellulose-tannin films: From trees to sustainable active packaging. Journal of Cleaner Production 184: 143-151.

- Peelman N, Ragaert P, De Meulenaer B, Adons D, Peeters R, et al. (2013) Application of bioplastics for food packaging. Trends in Food Science & Technology 32: 128-141.

- Swaroop C, Shukla M (2018) Nano-magnesium oxide reinforced polylactic acid biofilms for food packaging applications. International Journal of Biological Macromolecules 113: 729-736.

- Beverlya RL, Janes ME, Prinyawiwatkula W, No HK (2008) Edible chitosan films on ready-to-eat roast beef for the control of Listeria monocytogenes. Food Microbiol 25: 534-537.

- Espitia PJP, Du WX, Avena-Bustillos RJ, Soares NFF, McHugh TH (2014) Edible films from pectin: Physical-mechanical and antimicrobial properties-A review. Food Hydrocolloids 35: 287-296.

- Babu RP, O'Connor K, Seeram R (2013) Current progress on bio-based polymers and their future trends. Progress in Biomaterial 2: 1-16.

- Tang XZ, Kumar P, Alavi S, Sandeep KP (2012) Recent advances in biopolymers and biopolymer-based nanocomposites for food packaging materials. Critical Reviews in Food Science and Nutrition 52: 426-442.

- Wang S, Marcone MF, Barbut S, Lim LT (2012) Fortification of dietary biopolymers-based packaging material with bioactive plant extracts. Food Research International 49: 80-91.

- Wang H, Qian J, Ding F (2018) Emerging chitosan-based films for food packaging applications. Journal of Agricultural and Food Chemistry 66: 395-413.

- Wang J, Tavakoli J, Tang Y (2019) Bacterial cellulose production, properties and applications with different culture methods-A review. Carbohydrate Polymers 219: 63-76.

- Melo PTS, Otoni CG, Barud HS, Aouada FA, de Moura MR (2020) Upcycling microbial cellulose scraps into nanowhiskers with engineered performance as fillers in all-cellulose composites. ACS Applied Materials & Interface 12: 46661-46666.

- Mohamed SAA, El-Sakhawy M, El-Sakhawy MAM (2020) Polysaccharides, protein and lipid -based natural edible films in food packaging: A review. Carbohydrate Polymers 238: 116178.

- Puscaselu R, Gutt G, Amariei S (2019) Biopolymer-based films enriched with Stevia rebaudiana used for the development of edible and soluble packaging. Coatings 9: 360.

- Ngo TMP, Nguyen TH, Dang TMQ, Tran TX, Rachtanapun P (2020) Characteristics and antimicrobial properties of active edible films based on pectin and nanochitosan. International Journal of Molecular Sciences 21: 2224.

- Priyadarshi R, Kim HJ, Rhim JW (2021) Effect of sulfur nanoparticles on properties of alginate-based films for active food packaging applications. Food Hydrocolloids 110: 106155.

- Roy S, Rhim JW (2020) Effect of CuS reinforcement on the mechanical, water vapor barrier, UV-light barrier, and antibacterial properties of alginate-based composite films. International Journal of Biological Macromolecules 164: 37-44.

- LI H, Shi H, He Y, Fei X, Peng L (2020) Preparation and characterization of carboxymethyl cellulose-based composite films reinforced by cellulose nanocrystals derived from pea hull waste for food packaging applications. International Journal of Biological Macromolecules 164: 4104-4112.

- Alizadeh-sani M, Mohammadian E, McClements DJ (2020) Eco-friendly active packaging consisting of nanostructured biopolymer matrix reinforced with TiO2 and essential oil: Application for preservation of refrigerated meat. Food Chemistry 322: 126782.

- Burt S (2004) Essential oils: Their antibacterial properties and potential applications in foods-a review. International Journal of Food Microbiology 94: 233-253.

- Pires VGA, de Moura MR (2017) Preparação de novos filmes poliméricos contendo nanoemulsões do óleo de melaleuca, copaíba e limão para aplicação como biomaterial. Química Nova 40: 1-5.

- Wan J, Wilcock A, Coventry MJ (1998) The effect of essential oils of basil on the growth of Aeromonas hydrophila and Pseudomonas fluorescens. Journal of Applied Microbiology 84: 152-158.

- Bonilla J, Atarés L, Vargas M, Chiralt A (2012) Effect of essential oils and homogenization conditions on properties of chitosan-based films. Food Hydrocolloids 26: 9-16.

- Perdones A, Escriche I, Chiralt A, Vargas M (2016) Effect of chitosan-lemon essential oil coatings on volatile profile of strawberries during storage. Food Chemistry 197: 979-986.

- Tongnuanchan P, Benjakul S, Prodpran T, Pisuchpen S, Osako K (2016) Mechanical, thermal and heat sealing properties of fish skin gelatin film containing palm oil and basil essential oil with different surfactants. Food Hydrocolloids 56: 93-107.

- Sánchez-González L, Cháfer M, Chiralt A, González-Martínez C (2010) Physical properties of edible chitosan films containing bergamot essential oil and their inhibitory action on Penicillium italicum. Carbohydrate Polymers 82: 386-392.

- Pranoto Y, Salokhe VM, Rakshit SK (2005) Physical and antibacterial properties of alginate-based edible film incorporated with garlic oil. Food Research International 38: 267-272.

- Riquelme N, Herrera ML, Matiacevich S (2017) Active films based on alginate containing lemongrass essential oil encapsulated: Effect of process and storage condition. Food and Bioproducts Processing 104: 94-103.

- López P, Sánchez C, Batlle R, Nerín C (2007) Development of flexible antimicrobial films using essential oils as active agents. Journal of Agricultural and Food Chemistry 55: 8814-8824.

- Carocho M, Morales P, Ferreira ICFR (2015) Natural food additives: Quo vadis? Trends in Food Science & Technology 45: 284-295.

- Thogersen J (1996) Wasteful food consumption: Trends in food and packaging waste. Scandinavian Journal of Management 12: 291-304.

- Regulation (EC) No 1935/2004 of the European Parliament and of the Council of 27 October 2004 on materials and articles intended to come into contact with food and repealing Directives 80/590/EEC and 89/109/EEC.

- 2002/113/EC: Commission Decision of 23 January 2002 amending Commission Decision1999/217/EC as regards the register of flavoring substances used in or on foodstuffs.

- Buonocore GG, Conte A, Corbo MR, Sinigaglia M, Del Nobile MA (2005) Mono- and multilayer active films containing lysozyme as an antimicrobial agent. Innovative Food Science and Emerging Technologies 6: 459-464.

- Rubio AL, Almenar E, Hernandez-Muñoz P, Lagarón JM, Catalá R, et al. (2004) Overview of active polymer-based packaging technologies for food applications. Food Reviews International 20: 357-387.

- Chen MC, Yeh GHC, Chiang BH (1996) Antimicrobial and physicochemical properties of methylcellulose and chitosan films containing a preservative. Journal of Food Processing and Preservation 20: 379-390.

- Debeaufort F, Quezada-Gallo JA, Voilley A (1998) Edible films, and coatings: tomorrow’s packaging: A review. Critical Reviews in Food Science and Nutrition 38: 299-313.

- Viuda-Martos M, Mohamady MA, Fernández-López J, ElRazik KAA, Omer EA, et al. (2011) In vitro antioxidant and antibacterial activities of essential oils obtained from Egyptian aromatic plants. Food Control 22: 1715-1722.

- Vermeiren L, Devlieghere F, van Beest M, de Kruijf N, Debevere J (1999) Developments in the active packing of foods. Trends in Food Science and Technology 10: 77-86

- Ruiz-Navajas Y, Viuda-Martos M, Perez-Alvarez JA, Fernández-López J (2013) In vitro antibacterial and antioxidant properties of chitosan edible films incorporated with Thymus moroderi or Thymus piperella essential oils. Food Control 30: 386-392.

- Seydim AC, Sarikus G (2006) Antimicrobial activity of whey protein based edible films incorporated with oregano, rosemary, and garlic essential oils. Food Research International 39: 639-644.

- Appendini P, Hotchkiss JH (2002) Review of antimicrobial food packaging. Innovative Food Science & Emerging Technologies 3: 113-126.

- Arques JL, Rodríguez E, Nuñez M, Medina M (2008) Inactivation of Gram-negative pathogens in 688 refrigerated milk by reuterin in combination with nisin or the lactoperoxidase system. European Food Research and Technology 227: 77-82.

- Dopico-Garcia MS, Castro-López MM, López-Vilariño JM, González-Rodríguez MV, Valentão P, et al. (2010) Natural extracts as potential source of antioxidants to stabilize polyolefins. Journal of Applied Polymer Science 119: 3553-3559.

- Barbosa-Pereira L, Cruz JM, Sendón R, de Quirós ARB, Ares A, et al. (2013) Development of antioxidant active films containing tocopherols to extend the shelf life of fish. Food Control 31: 236-243.

- Maisuthisakul P, Suttajit M, Pongsawatmanit R (2007) Assessment of phenolic content and free radical scavenging capacity of some Thai indigenous plants. Food Chemistry 100: 1409-1418.

- Silva MLC, Costa RS, Santana AS, Koblitz MGB (2010) Phenolic compounds, carotenoids and antioxidant activity in plant products. Seminar: Ciências Agrárias 31: 669-682.

- Laguerre M, Lecomte J, Villeneuve P (2007) Evaluation of the ability of antioxidants to counteract lipid oxidation: Existing methods, new trends, and challenges. Progress in Lipid Research 46: 244-282.

- Guilbert S, Gontard N (2003) Agro-polymers for edible and biodegradable films: Review of agricultural polymeric materials, physical and mechanical characteristics. In: Innovations in Food Packaging. Han JH (edn). Academic Press. London, UK.

- Buonocore GG, Nobile MAD, Panizza A, Bove S, Battaglia G, et al. (2003) Modeling the lysozyme release kinetics from antimicrobial films intended for food packaging applications. Journal of Food Science 68: 1365-1370.

Citation: Bonfim KS, Pereira ABB, de Lima TA, de Oliveira EFR, dos Santos VS, et al. (2021) Active Polymeric Packaging: Innovation in Food with Potential Use of Sustainable Raw Material. J Food Sci Nutr 7: 112.

Copyright: © 2021 Kely S Bonfim, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.