Chemical Composition, Anti-Nutrients and Functional Properties of Composite Flours Formulated from Wheat and Three Cultivars of Cocoyam Corms (Xanthosoma sagittifolium) Commonly Found in Nigeria

*Corresponding Author(s):

Olusegun Ayodele OlaoyeDepartment Of Food Science And Technology, Michael Okpara University Of Agriculture, Umudike, Nigeria

Tel:+234 7058495436,

Email:olaayosegun@yahoo.com

Abstract

Three cultivars of cocoyam (Xanthosoma sagittifolium) were processed into flour and used to formulate composite flours with wheat at percentage substitutions of 5 and 10%. The chemical composition, anti-nutrients and functional properties of composite flours were determined. Results indicate that Ede Ofecultivar (EOF131) had the highest water absorption capacity of 1.70 mg/mL While Wheat Flour (WHF101) recorded the lowest. WHF101 had the highest contents of absorption and swelling capacities, 2.20 g/mL and 8.50 g/g, respectively. The Ede Ocha cultivar contained significantly higher content (P < 0.05) of phytate (0.19%) than others. The three whole cocoyam flours were generally higher in the anti-nutrient properties of tannin, alkaloid and saponin than WHF101. The WHF101 flour sample had higher contents of Ca, Mg, Na, K and P than others. The composite flours containing 5% each of cocoyam flour cultivars were generally comparable with those of wheat flour and did not differ significantly (P > 0.05). The study concluded that the composite flours may find relevance in food applications, especially in the production of baked food products especially in developing countries.

Keywords

INTRODUCTION

Composite flours are mixtures of different vegetable flours-rich in starch, protein, and/or other nutrients, with or without wheat flour. Several institutions, including the Food and Agriculture Organization, have been involved in research designed to find ways of partially substituting wheat flour with those from other sources or replacing wheat all together [1].

Composite flours could also be regarded as blends of wheat and other flours, or wholly non-wheat blends of flours for the production of various food products including baked products, pastas, porridges, and snack foods [2]. According to the latter authors, the purpose of composite flour for making staple foods such as baking items is usually for economic and nutritional advantages. The use of composite flours of wheat and other vegetable flours for making baked food products such as biscuit and bread in tropical countries may be associated with scarcity of wheat, due to climatic reasons for its propagation. Composite flours are quite different from the ready-mixed flours familiar to millers and bakers, as the latter contain all the non-perishable constituents of the recipe for certain baked products.

Cocoyams (Xanthosoma sagittifolium) are used as subsistence staples in many parts of the tropics and sub-tropics, especially Nigeria. They are grown primarily for their edible starch contained in their corms, and secondarily the leaves are used as vegetable in most developing countries [3]. The proximate composition of cocoyam corm showed moisture (80.99%), ash (1.03%), crude protein (5.47%), crude fat (0.20%), crude fibre (1.28%) and total carbohydrate of 11.03% [4]. Nigeria is the largest producer of cocoyam in the world with an annual production of above 3.450 million metric tonnes; this represents 72.2%, 57.7% and 45.9% of total production in West Africa, Africa and the World respectively [5].

Cocoyam corms generally have been noted to contain anti nutrients and high moisture content; the latter has been associated with high rate of deterioration of the crop after harvest, resulting in its limited shelf life and unavailability. Processing of cocoyam into semi-finished forms such as flours could help prevent associated losses and promote its availability and utilization in various food applications.With the constant increase in the consumption of bread and other baked products in many developing countries, coupled with the high foreign exchange involved in wheat importation and ever-growing urban populations, the composite flour technology involving incorporation of cocoyam flour could be very useful. The present study therefore aimed at assessing certain quality indices of flours produced from three cultivars of cocoyam commonly found in Nigeria, along with their composites with wheat. Results may help proffer suggestions on their possible suitability in food applications such as baked products for likely commercialization.

MATERIALS AND METHODS

Source of raw material

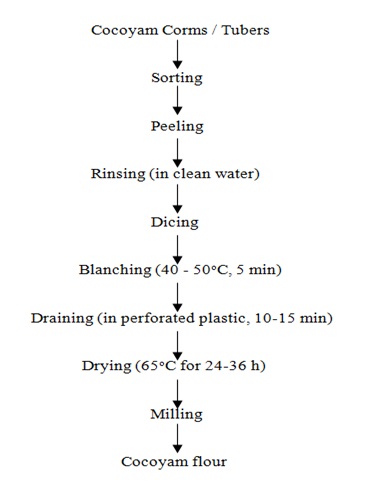

Processing of cultivars of cocoyam corms into flour: The unit operations involved in the processing of the cultivars of cocoyam corms into flour is represented in figure 1. The cocoyam corms were sorted to remove defective ones and then peeled. They were thoroughly rinsed in clean water to remove any adhering dirt’s that may result from the peeling process. They were then diced into small sizes (0.5×3.5×5 mm) and blanched at 45±5oC for 5 min to eliminate possible occurrence of enzymatic reactions. The blanched cocoyam dices were drained of water using clean plastic containers and dried in air drying oven (Gallenkamp, USA) at 65oC for 24-36 h. They were then milled using hammer mill machine (tiger-extruda 6.5 hp, UK) and sieved (using 0.02 µm mess size sieves) to obtain cocoyam flour.

Figure 1: Flow chart of the production of cocoyam flour.

Figure 1: Flow chart of the production of cocoyam flour.Formulations used for preparation of the wheat-cocoyam composite flours:

|

Flours Type |

Wheat Flour |

Ede Ocha Cocoyam Flour |

Ede Uhie Cocoyam Flour |

Ede Ofe Cocoyam Flour |

|

WHF101 |

100 |

- |

- |

- |

|

EOC111 |

- |

100 |

- |

- |

|

EUH121 |

- |

- |

100 |

- |

|

EOF131 |

- |

- |

- |

100 |

|

EOC112 |

95 |

5 |

- |

- |

|

EOC113 |

90 |

10 |

- |

- |

|

EUH122 |

95 |

- |

5 |

- |

|

EUH123 |

90 |

- |

10 |

- |

|

EOF132 |

95 |

- |

- |

5 |

|

EOF133 |

90 |

- |

- |

10 |

Evaluation of functional properties of the flours:

Evaluation of anti-nutrient in the flours: Oxalate in the wheat-cocoyam flour mixtures was determined using the method of Leyva et al. [11], while tannins, phytates, alkaloid and saponins were analyzed using the methods of AOAC [12].

Proximate composition of the flours: The proximate compositions of the different flour mixtures, including moisture, ash, fat, and protein were determined using the methods of Association of Official Analytical Chemists [12]. Carbohydrate was determined by difference.

Mineral composition of the flours: The methods described by Saura-Calixto et al. [13], and Bonire et al. [14], were used for determinations of mineral contents in the flour mixtures. Potassium and sodium were determined by digesting the ash of the samples with perchloric acid and nitric acid, and then taking the readings on Jenway digital flame photometer (spectronic 20). Phosphorus was determined by vanado-molybdate colorimetric method. Calcium and magnesium were determined spectrophotometrically by using Buck 200 atomic absorption spectrophotometer (Buck Scientific, Norwalk) and compared with absorption of standards of the minerals.

Determination of amylose and amylopectin in flours: Amylose content was determined using the modified method of Hoover and Ratnayake [15]. One hundred milligrams (100 mg) of the flour samples were weighed into volumetric flask (100mL capacity) and 1mL of 99.7% (v/v) ethanol was added followed by addition of 9mL of 1N-sodium hydroxide (NaOH). The flask was then was covered with parafilm or foil and the content was mixed well by swirling gently. The content of the flask was heated for 10 min in boiling water inside water bath, after which it was removed and allowed to cool. The flask was filled up to the mark with distilled water and shaken well. About 5mL of the mixture was pipette into another 100mL volumetric flask, acetic acid (1N, 1.0mL) and 2mL of iodine solution were added, and then filled to mark with distilled water. Absorbance (A) was taken using spectrophotometer at 620nm wavelength. The blank containing 1mL of ethanol and 9mL of sodium hydroxide was similarly treated. The amylose content was calculated as:

Amylose content (%) = 3.06×A×20

= 61.20×A

Where A = Absorbance value.

Amylopectin was calculated by subtracting the amylose content from 100.

STATISTICAL ANALYSIS

Data which depended on different percentages of substitutions of different flour samples were analyzed according to a completely randomized design with three replicates. Data were subjected to variance analyses and differences between means were evaluated by Duncan’s multiple range tests using SPSS statistic programmed, version 10.01. Significant differences were expressed at P < 0.05.

RESULTS AND DISCUSSION

In this study, composite flours were formulated from wheat and five varieties of cocoyam (Table 1). The functional properties of the different flour formulations from the wheat-cocoyam flours are shown in table 2. The highest water absorption capacity (1.79 g/mL) was recorded for sample EOC113 while lowest values of 1.30 each were obtained for WHF101 and EUH122 samples. Significant difference (P < 0.05) was observed among some of the samples, which may have been impacted by the different cocoyam cultivars used in their formulations. The WHF101 sample recorded the highest oil absorption capacity (2.18 g/mL), and were closely followed by those obtained for EOF132, EOF133, EOC112 and EUH122 respectively, all of which did not differ significantly from each other (P > 0.05). The similarities in their oil absorption capacities may indicate their suitability for use in processing of same category of foods, especially baked products; although other useful functional properties should be taken into consideration.

|

Flours Type |

Water Absorption Capacity (g/mL) |

Oil Absorption Capacity (g/mL) |

Swelling Capacity(g/g) |

Bulk Density(g/mL) |

Gelling Capacity (%) |

|

WHF101 |

1.30c±0.14 |

2.20a±0.00 |

8.50a±0.00 |

0.71a±0.01 |

6.00d±0.00 |

|

EOC111 |

1.60ab±0.00 |

1.32e±0.03 |

7.40d±0.14 |

0.63e±0.00 |

8.00a±0.00 |

|

EUH121 |

1.50abc±0.00 |

1.40d±0.00 |

7.60c±0.00 |

0.61e±0.00 |

8.00a±0.00 |

|

EOF131 |

1.70a±0.00 |

1.95c±0.07 |

7.60c±0.00 |

0.63e±0.00 |

8.00a±0.00 |

|

EOC112 |

1.31bc±0.14 |

2.17ab±0.03 |

8.35ab±0.14 |

0.70ab±0.01 |

6.10c±0.00 |

|

EOC113 |

1.32bc±0.14 |

2.13ab±0.03 |

8.30b±0.14 |

0.67bc±0.01 |

6.20b±0.00 |

|

EUH122 |

1.30c±0.14 |

2.16ab±0.00 |

8.46ab±0.00 |

0.69abc±0.01 |

6.10c±0.00 |

|

EUH123 |

1.32bc±0.14 |

2.12b±0.00 |

8.41ab±0.00 |

0.66c±0.01 |

6.20b±0.00 |

|

EOF132 |

1.31bc±0.14 |

2.18ab±0.00 |

8.46ab±0.00 |

0.70ab±0.01 |

6.10c±0.00 |

|

EOF133 |

1.33bc±0.14 |

2.17ab±0.00 |

8.41ab±0.00 |

0.67bc±0.00 |

6.20b±0.00 |

WHF101, 100% wheat; EOC111, 100% Ede Ocha; EUH121, 100% Ede Uhie; EOF131, 100% Ede Ofe; EOC112, 95% wheat + 5% Ede Ocha; EOC113, 90% wheat + 10% Ede Ocha; EUH122, 95% wheat + 5% Ede Uhie; EUH123, 90% wheat + 10% Ede Uhie; EOF132, 95% wheat + 5% Ede Ofe; EOF133, 90% wheat + 10% Ede Ofe.

The swelling capacity ranged from 7.40 to 8.50 g/g with varying degrees of significant difference being noted among samples; WHF101 similarly had the highest value (0.71 g/mL) of bulk density, and this was observed to differ significantly from those recorded for some of the other samples. In contrast, WHF101 had the lowest gelling capacity (6.0%) compared with those observed for others. The highest gelling capacity (8.0) was recorded for each of EOC111, EOF131 and EUH121. The results of the functional properties of the flour samples in this study were similar to those contained in research investigations of other researchers; Pasha et al. [16], reported the rheological and functional properties of pumpkin-wheat composite flour in Pakistan. Chandra et al. [2], also carried out evaluation of functional properties of rice/sweet potato and wheat composite flours; the investigators used the composite flours to produce biscuits and concluded favorable comparison with those produced from whole wheat flour. More recently, Okoye and Obi [17] determined the chemical composition and sensory properties of wheat-African yam bean composite flour cookies. It thus becomes apparent that the composite flours of the wheat-cocoyam in the present study may be of significance in the production of baked food items; this may possible be scaled up to commercial level in reducing cost of importation of wheat which does not normally thrive in Nigeria for climatic reasons [18]. However, their successful trials in pilot experiments will be necessary before probable commercialisation.

All the functional properties recorded in this study, with the exception of bulk density, were slightly lower than those reported in a previous investigation by Olaoye et al. [19]. The difference may be attributed to varietal difference in the cocoyam cultivars used in the respective studies. Functional properties are intrinsic physico-chemical characteristics which affect the behaviour of properties in food systems during processing, manufacturing, storage and preparation [20]. Oil absorption capacity is one of the functional properties of flours which is influenced by the lipophilic characteristics; the low level of this functional property in the flour samples being reported is therefore justified by the low fat nature of cocoyam, being a carbohydrate crop. Furthermore, Tharise et al. [10], noted that protein may also have effect on the oil absorption capacity, which further justifies the low level of this property recorded in the cocoyam flour samples because cocoyam is low in protein. Judging from the results of their functional properties, the wheat-cocoyam flour samples in this study may be suitable in food applications involving baking, especially in the making of bread and biscuits/cookies [10,17].

The antinutrient compositions (%) of the flours are presented in table 3. Results indicate that EOC111 had the highest phytate content of 0.190 compared with the lowest (0.021) recorded for EOC113; hence the Ede Ocha cocoyam cultivar was lower in phytate content than other cultivars. The highest value of 1.60 was obtained for antinutrient content of oxalate, and this was noted for the EUH121 flour, while the lowest value (0.66) was recorded for WHF101 (whole wheat flour). Among the flours prepared from the various cocoyam cultivars, EOF132 had the lowest oxalate, 0.68. The oxalate content of the whole wheat flour was significantly different (P < 0.05) from most of the other composite flours of wheat and cocoyam. Tannin contents ranged from 0.773 to 0.929, with the lower and upper values being obtained for WHF101 and EOF131 samples respectively; this indicates that the latter had the highest tannin among other cocoyam flours. However, no significant difference (P > 0.05) was observed among most of the composite flours and their whole cocoyam counterparts, with the exception of EOC111, EOF131 and EUH121. Alkaloid assumed similar trend to that of tannin, with the WHF101 flour sample having the lowest content (0.19) while EUH121 had the highest, 0.49. Significant difference (P < 0.05) was recorded in the alkaloid contents of the whole wheat flour and other whole flours of the different cocoyam cultivars. The whole wheat flour also had the lowest saponin among the flour samples; the whole cocoyam flours were higher than their wheat-cocoyam composites. Therefore composites of cocoyam and wheat flours may help lower the risk of antinutrients in food processing and applications.

|

Flours Type |

Phytate |

Oxalate |

Tannin |

Alkaloid |

Saponins |

|

WHF101 |

0.040b±0.006 |

0.66g±0.00 |

0.773e±0.022 |

0.19d±0.01 |

0.50c±0.00 |

|

EOC111 |

0.190e±0.000 |

1.54b±0.00 |

0.821c±0.006 |

0.40b±0.00 |

1.02b±0.03 |

|

EUH121 |

0.022cd±0.000 |

1.60a±0.00 |

0.861b±0.003 |

0.49a±0.01 |

1.00b±0.00 |

|

EOF131 |

0.026a±0.000 |

1.32c±0.00 |

0.929a±0.003 |

0.38b±0.02 |

1.42a±0.10 |

|

EOC112 |

0.022cd±0.001 |

0.69fg±0.02 |

0.790de±0.000 |

0.21cd±0.02 |

0.53c±0.05 |

|

EOC113 |

0.021d±0.000 |

0.74de±0.01 |

0.792de±0.001 |

0.22cd±0.00 |

0.53c±0.00 |

|

EUH122 |

0.023bc±0.000 |

0.70efg±0.01 |

0.792de±0.002 |

0.22cd±0.00 |

0.53c±0.04 |

|

EUH123 |

0.022cd±0.000 |

0.75d±0.04 |

0.796d±0.002 |

0.23c±0.00 |

0.55c±0.04 |

|

EOF132 |

0.023bc±0.000 |

0.68fg±0.00 |

0.795d±0.005 |

0.21cd±0.00 |

0.55c±0.01 |

|

EOF133 |

0.022cd±0.000 |

0.72def±0.02 |

0.803d±0.004 |

0.22cd±0.01 |

0.60c±0.02 |

WHF101, 100% wheat; EOC111, 100% Ede Ocha; EUH121, 100% Ede Uhie; EOF131, 100% Ede Ofe; EOC112, 95% wheat + 5% Ede Ocha; EOC113, 90% wheat + 10% Ede Ocha; EUH122, 95% wheat + 5% Ede Uhie; EUH123, 90% wheat + 10% Ede Uhie; EOF132, 95% wheat + 5% Ede Ofe; EOF133, 90% wheat + 10% Ede Ofe.

Presence of antinutrients, especially at high levels in vegetable flours may have adverse effect during food processing. This is due to their ability to react with certain components of food thereby forming complexes, which make such food components unavailable for use by the body [21]. Reed et al. [22], have reported the ability of tannin to react with protein, thereby making it nutritionally unavailable. Furthermore, phytates and oxalates have been noted to form insoluble salts with mineral elements such as zinc, calcium and iron and thereby such minerals for utilization in the body [23]. The antinutrients of the cocoyam flours in the current study were observed to be lower than those reported in previous studies [18,24], probably due to differences in the processing techniques adopted during production. This observation could be of benefit during eventual food applications of the cocoyam flours in reducing possibilities of unavailability of nutrients normally caused by presence of antinutrients.

The results of proximate compositions of the different flours show that moisture ranged from 9.24 to 13.30 among samples, some of which show varying degrees of significance difference (Table 4). The WHF101 sample had lower ash content (2.50%) than others, indicating that ash contents were higher in all whole cocoyam flours and wheat-cocoyam composites, and these were noted to be significantly different (P < 0.05). The observation was consistent with various reports in the literature that vegetable flours normally contain relatively high mineral contents, and this constitutes one of reasons why composite flour technology has been advocated and encouraged in the production of composite breads and other baked products [1,2]. Fiber, fat and protein contents ranged from 2.07-3.15, 1.10-2.40, and 8.71-15.84 respectively among the flour samples; WHF101 recorded highest values in the three proximate parameters. However, no significant difference was recorded between the WHF101 sample and some of the composite flours in the attributes of fibre and fat, while protein differs significantly between WHF101 and other samples. In a research study by Olaoye et al. [19], which investigated the effects of sprouting on quality attributes of cocoyam flour and its performance as composite of wheat in bread production, protein content was reported to be higher in wheat than cocoyam. Malomo et al. [25], also demonstrated higher protein content in wheat flour than vegetable flours obtained from breadfruit and breadnut. It thus appears that except in cowpea vegetable flours and other few cases, protein contents of wheat flour are higher than their vegetable crop counterparts [26].

|

Flours Type |

Moisture |

Ash |

Fiber |

Fat |

Protein |

Carbohydrate |

|

WHF101 |

9.24e±0.05 |

2.50d±0.00 |

3.15a±0.21 |

2.40a±0.14 |

15.84a±0.16 |

66.87d±0.15 |

|

EOC111 |

13.30a±0.14 |

3.00b±0.00 |

2.07b±0.09 |

2.02b±0.03 |

8.75f±0.00 |

70.85b±0.27 |

|

EUH121 |

12.10b±0.14 |

3.05b±0.07 |

2.00b±0.00 |

1.60c±0.14 |

8.90ef±0.00 |

72.35a±0.21 |

|

EOF131 |

11.22c±0.31 |

3.45a±0.07 |

3.00a±0.00 |

1.10d±0.14 |

9.12e±0.02 |

72.10a±0.13 |

|

EOC112 |

9.43de±0.05 |

2.52d±0.00 |

3.10a±0.21 |

2.37a±0.14 |

15.47bc±0.16 |

67.11cd±0.15 |

|

EOC113 |

9.63d±0.05 |

2.55cd±0.00 |

3.05a±0.21 |

2.35ab±0.14 |

15.11d±0.16 |

67.31cd±0.15 |

|

EUH122 |

9.37de±0.05 |

2.53cd±0.00 |

3.10a±0.21 |

2.34ab±0.14 |

15.48bc±0.16 |

67.18cd±0.15 |

|

EUH123 |

9.51de±0.05 |

2.56cd±0.00 |

3.05a±0.21 |

2.30ab±0.14 |

15.13d±0.16 |

67.45c±0.15 |

|

EOF132 |

9.32de±0.05 |

2.53cd±0.00 |

3.00a±0.00 |

2.33ab±0.14 |

15.50b±0.16 |

67.30cd±0.36 |

|

EOF133 |

9.41de±0.05 |

2.60c±0.00 |

2.99a±0.01 |

2.27ab±0.14 |

15.15cd±0.16 |

67.57c±0.36 |

WHF101, 100% wheat; EOC111, 100% Ede Ocha; EUH121, 100% Ede Uhie; EOF131, 100% Ede Ofe; EOC112, 95% wheat + 5% Ede Ocha; EOC113, 90% wheat + 10% Ede Ocha; EUH122, 95% wheat + 5% Ede Uhie; EUH123, 90% wheat + 10% Ede Uhie; EOF132, 95% wheat + 5% Ede Ofe; EOF133, 90% wheat + 10% Ede Ofe.

The mineral compositions (mg/100g) of the wheat-cocoyam flours are shown in table 5. Results indicate that the highest calcium content was recorded for sample EOC112 while EUH121 had the lowest. A value of 40.10 was recorded for whole wheat flour. Magnesium ranged from 22.30 to 26.01, obtained for samples EUH121 and EUH122 respectively. Sodium content was observed to be highest (124.44) for WHF101 and lowest (32.45) for EUH121 samples. A range of 104.53 to 146.43 was recorded for potassium, with WHF101 having the highest value. Phosphorus was also highest (38.18) for WHF101 while the lowest (36.30) was obtained EOC111; no significance difference (P < 0.05) was observed among most of the flour samples in terms of phosphorus contents. It is interesting to note that calcium, magnesium and phosphorous contents of whole cocoyam and wheat-cocoyam composite flour samples compare favourably with those of the Whole Wheat Flour (WHF101), indicating that useful mineral elements are contained in cocoyam which may be beneficial to consumers. The results of the calcium in the cocoyam flour samples in the present study are very similar to those reported in a research investigation by Alcantara et al. [24], in two cocoyam varieties (NSIC G-9 and VG-2) in the Philippines. The magnesium and calcium contents recorded in a cocoyam variety by Agoreyo et al. [27], also compared favourable with those obtained in the present study.

|

Flours Type |

Calcium |

Magnesium |

Sodium |

Potassium |

Phosphorous |

|

WHF101 |

40.10a±0.14 |

25.20ab±0.00 |

124.44a±0.03 |

146.43a±0.14 |

38.18a±0.08 |

|

EOC111 |

37.20b±0.28 |

22.80c±0.00 |

37.20g±0.04 |

108.50h±0.09 |

36.30d±0.14 |

|

EUH121 |

34.10d±0.14 |

22.30c±0.14 |

32.45i±0.04 |

112.31g±0.05 |

36.69c±0.00 |

|

EOF131 |

36.15c±0.07 |

22.70c±0.14 |

35.32h±0.00 |

104.53i±0.08 |

37.10b±0.06 |

|

EOC112 |

40.24a±0.28 |

25.05ab±0.04 |

120.12b±0.09 |

144.69b±0.09 |

38.09a±0.08 |

|

EOC113 |

40.08a±0.28 |

24.93b±0.04 |

115.76d±0.09 |

142.78e±0.07 |

37.98a±0.06 |

|

EUH122 |

40.10a±0.29 |

26.01a±1.36 |

119.81c±0.00 |

144.87b±0.07 |

38.11a±0.09 |

|

EUH123 |

39.77a±0.26 |

24.86b±0.04 |

115.21f±0.00 |

143.15d±0.06 |

38.02a±0.08 |

|

EOF132 |

40.17a±0.26 |

25.08ab±0.00 |

119.99b±0.06 |

144.49c±0.08 |

38.14a±0.11 |

|

EOF133 |

39.97a±0.27 |

24.95b±0.01 |

115.56e±0.08 |

142.39f±0.09 |

38.04a±0.07 |

WHF101, 100% wheat; EOC111, 100% Ede Ocha; EUH121, 100% Ede Uhie; EOF131, 100% Ede Ofe; EOC112, 95% wheat + 5% Ede Ocha; EOC113, 90% wheat + 10% Ede Ocha; EUH122, 95% wheat + 5% Ede Uhie; EUH123, 90% wheat + 10% Ede Uhie; EOF132, 95% wheat + 5% Ede Ofe; EOF133, 90% wheat + 10% Ede Ofe.

There was no significant difference (P > 0.05) between the amylose and amylopectin contents of the various flour samples (Table 6). This indicates that the flour samples may assume similar viscosity patterns in recipe formulations and food products, where they form part of ingredients for production [28].

|

Sample |

Amylose |

Amylopectin |

|

WHF101 |

15.75a±0.07 |

84.25a±0.07 |

|

EOC111 |

15.81a±0.02 |

84.19a±0.02 |

|

EUH121 |

15.85a±0.05 |

84.15a±0.05 |

|

EOF131 |

15.80a±0.28 |

84.20a±0.28 |

|

EOC112 |

15.76a±0.05 |

84.24a±0.05 |

|

EOC113 |

15.77a±0.04 |

84.23a±0.04 |

|

EUH122 |

15.76a±0.01 |

84.24a±0.01 |

|

EUH123 |

15.77a±0.07 |

84.23a±0.07 |

|

EOF132 |

15.75a±0.00 |

84.25a±0.00 |

|

EOF133 |

15.76a±0.08 |

84.24a±0.08 |

WHF101, 100% wheat; EOC111, 100% Ede Ocha; EUH121, 100% Ede Uhie; EOF131, 100% Ede Ofe; EOC112, 95% wheat + 5% Ede Ocha; EOC113, 90% wheat + 10% Ede Ocha; EUH122, 95% wheat + 5% Ede Uhie; EUH123, 90% wheat + 10% Ede Uhie; EOF132, 95% wheat + 5% Ede Ofe; EOF133, 90% wheat + 10% Ede Ofe.

This study concluded that cocoyam flours possessed functional properties which may make them useful in composite flour technology for use in production of baked food products, especially in Nigeria where the cocoyam cultivars are common and have been underutilised. The minerals and minimal contents of antinutrients recorded in the cocoyam flours could also promote their potential for use in other food applications, and may help enhance nutritional intake among consumers. Further studies are however required to practically explore food application potentials of the cocoyam flours, the results of which may be scaled up to commercial level if successful in preliminary pilot trials.

REFERENCES

- Olaoye OA, Ade-Omowaye BIO (2011) Composite flours and breads: Potential of local crops in developing countries. In: Preedy VR, Watson RR, Patel VB (eds.). Flour and breads and their fortification in health and disease prevention. Academic Press, London, UK. Pg No: 183-192.

- Chandra S, Singh S, Kumari D (2015) Evaluation of functional properties of composite flours and sensorial attributes of composite flour biscuits. J Food Sci Technol 52: 3681-3688.

- Aregheore E, Perera D (2003) Dry matter, nutrient composition and palatability/acridity of eight exotic cultivars of cocoyams-taro (Colocasia esculenta) in Samoa. Plant Food Hum Nutr 58: 1-8.

- Chinnasarn S, Manyasi R (2010) Chemical and physical properties of taro flour and the application of restructured taro strip product. World Appl Sci J 9: 600-604.

- Falade KO, Okafor CA (2015) Physical, functional, and pasting properties of flours from corms of two Cocoyam (Colocasia esculenta and Xanthosoma sagittifolium) cultivars. J Food Sci Technol 52: 3440-3448.

- Mbofung CMF, Abuobakar YN, Njintang A, Abduoboubak BF (2006) Physicochemical and functional properties of six varieties of taro (Colocasia esculenta Schott) flour. J Food Technol 4: 135-142.

- Wang YC, Kinsella JE (1976) Functional properties of novel proteins: Alfalfa leaf protein. J Food Sci 41: 286-292.

- Abulud EFO (2001) Functional properties of cowpea (Vigna unguiculata Walp) seed sprayed with neem (Azadirachta indica) leaf extracts. Adv Food Sci 23: 68-71.

- Sathe SK, Ponte IG, Rangnekar PD, Salunkhe DK (1981) Effects of addition of great northern bean flour and protein concentrates on the rheological properties of dough and baking quality of bread. Cereal Chem 58: 97-100.

- Tharise N, Julianti E, Nurminah M (2014) Evaluation of physico-chemical and functional properties of composite flour from cassava, rice, potato, soybean and xanthan gum as alternative of wheat flour. Int Food Res J 21: 1641-1649.

- Leyva JAM, Artiga MPH, Mendez MMA, Perez JJQ (1990) Atomic absorption and UV-VIS absorption spectrophotometric determination of oxalate in urine by ligand exchange extraction. Clinica Chimica Acta 195: 47-56.

- AOAC, AOAC International (2005) Official methods of analysis of the AOAC International, (18th edn). AOAC International, Gaithersburg, USA.

- Saura-Calixto F, Cañellas J, Soler L (1983) Dietary fibre and components of the nitrogen-free extract of almond kernels. J Sci Food Agric 34: 1419-1422.

- Bonire JJ, Jalil NSN, Lori JA (1990) Sodium and potassium content of two cultivars of white yam (Dioscorea rotundata) and their source soils. J Sci Food Agric 53: 271-274.

- Hoover R, Ratnayake WS (2002) Starch characteristics of black bean, chick pea, lentil, navy bean and pinto bean cultivars grown in Canada. Food Chem 78: 489-498.

- Pasha I, Khan QAB, Butt MS, Saeed M (2013) Rheological and functional properties of pumpkin wheat composite flour. Pak J Food Sci 23: 100-104.

- Okoye JI, Obi CD (2017) Chemical composition and sensory properties of wheat-African yam bean composite flour cookies. Discourse J Agric Food Sci 5: 21-27.

- Olaoye OA, Onilude AA, Idowu OA (2006) Quality characteristics of bread produced from composite flours of wheat, plantain and soybeans. Afri J Biotechnol 5: 1102-1106.

- Olaoye OA, Agiriga AN, Ogada DC (2016) Investigating the effects of sprouting on quality attributes of cocoyam flour and its performance as composite of wheat in bread production. Annals Food Sci Technol 17: 93-101.

- Eltayeb ASM, Ali AO, Abou-Arab AA, Abu-Salem FM (2011) Chemical composition and functional properties of flour and protein isolate extracted from Bambara groundnut (Vigna subterranean). Afri J Food Sci 5: 82-90.

- Olaoye OA, Lawrence IG, Cornelius GN, Ihenetu ME (2015) Evaluation of quality attributes of cassava product (gari) produced at varying length of fermentation. American J Agric Sci 2: 1-7.

- Reed JD, Horvath PJ, Allen MS, Van Soest PJ (1985) Gravimetric determination of soluble phenolics including tannins from leaves by precipitation with trivalent ytterbium. J Sci Food Agric 36: 255-261.

- Sarkiyayi S, Agar TM (2010) Comparative analysis on the nutritional and anti-nutritional contents of the sweet and bitter cassava varieties. Adv J Food Sci Technol 2: 328-334.

- Alcantara RM, Wilma AH, Dizon E (2013) The nutritional value and phytochemical components of taro [Colocasia esculenta (L.) Schott] powder and its selected processed foods. Nutrition Food Sci. 3: 2-7.

- Malomo SA, Eleyinm AF, Fashakin JB (2011) Chemical composition, rheological properties and bread making potentials of composite flours from breadfruit, breadnut and wheat. Afr J Food Sci 5: 400-410.

- Ndife J, Abdulraheem LO, Zakari UM (2011) Evaluation of the nutritional and sensory quality of functional breads produced from whole wheat and soya bean flour blends. Afr. J Food Sci 5: 466-472.

- Agoreyo BO, Akpiroro HO, Orukpe OA, Osaweren OR, Owabor CN (2011) The effects of various drying methods on the nutritional composition of Musa paradisiaca, Dioscorea rotundata and colocasia esculenta. Asian J Biochem 6: 458-464.

- Oke MO, Bolarinwa IF (2012) Effect of fermentation on physicochemical properties and oxalate content of cocoyam (Colocasia esculenta) flour. Int Scholarly Res Net 2012: 1-4.

Citation: Olaoye OA, Obidegwe F (2018) Chemical Composition, Anti-Nutrients and Functional Properties of Composite Flours Formulated from Wheat and Three Cultivars of Cocoyam Corms (Xanthosoma sagittifolium) Commonly Found in Nigeria. J Food Sci Nut 4: 029.

Copyright: © 2018 Olusegun Ayodele Olaoye, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.