Differences in Physicochemical Characters of Fresh-Cut Mango, Mangosteen and Rambutan Due to Calcium Chloride Application

*Corresponding Author(s):

Luh SuriatiFood Science And Technology Department, Agriculture Faculty, Warmadewa University, Denpasar, Bali, Indonesia

Tel:+62 81347411966,

Email:suryatiluh1@gmail.com

Abstract

The effect of the application of calcium chloride on the physicochemical changes of fresh-cut tropical fruits during storage processes was evaluated. Furthermore, calcium chloride was applied on fresh-cut mango, mangosteen and rambutan, and then the physical changes during the storage process for 9 days was observed. The purpose of the study was to find out the influence of calcium chloride concentration and the time of immersion in inhibiting the physicochemical changes of fresh-cut mango, mangosteen and rambutan. The acidity, vitamin C, moisture content, total solids, weight loss, texture, and browning index for coated and uncoated samples are determined during the storage process of 3, 6, and 9 days respectively. Subsequently, the fresh-cut mangoes are prepared with seedless cuts, while mangosteen and rambutan are just fruit skin removal. The results showed that layered formulations have the potential to inhibit the physicochemical changes of fresh-cut mango and rambutan for 6 days and mangosteen for 9 days. The calcium chloride coating with a concentration of 1% and immersion time for 10 minutes is most effective compared to other treatments.

Keywords

Calcium chloride; Fresh-cut; Physicochemical change; Shelf-life; Tropical fruit

Introduction

The consumption of tropical fruits to strengthen the body's immune system has increased significantly during the COVID-19 pandemic. Subsequently, mangosteen, mango and rambutanare types that consumers appreciate, and inaddition to its delicious taste, it also contains functional components that are good for health. Furthermore, they are perishable commodities, rot easily and shrinkin weight with about 20-50%. The physiological damagetonon-edible parts such as the skin often determines the consumer preferences, although thee dible partisviable for consumption. The amount ofnon-edible is generally relatively high compared to the edible part (mangosteen 63-75%, mango 22-29%, rambutan 52-57%) and this contribute to the household waste [1]. This tends to increase sales of edible fruit from minimal processed products (what you see, what you eat) known asfresh-cut [2]. Inaddition, it is motivated by the need to consume equality products, freshness and lack of preparation time [3].

The minimal process is an attempt to prepare and handle products that have gone through processing stages such as stripping, cutting, slicing, pith removal, washing, packaging, etc [3,4]. The advantages of products with minimal or fresh-cut process include: serving consumers with a wide variety of choices, getting the required fresh quantity, making it easier to assess product quality, reducing product volume, and reducing transportation costs [5]. The weakness of fresh-cut fruits is that they are easily damaged and have a shorter shelf life than whole fruits [6].The minimal processing leads to the loss of the protective pericarp, tissue damage in such a way that the fruit undergoes physiological, pathological and physicochemical changes [7]. When fruits are cut or peeled, the tissue increases the respiratory rate, ethylene production, breaks down sensory components, induces ripening and causes unexpected metabolic production [8].

Calcium chloride can be applied directly to the surface of the fresh-cut fruit. According to [9], calcium can reduce the rate of respiration of the product, delay aging, extend shelf life and increase hardness [10]. Furthermore, the immersion in a calcium chloride solution leads to the formation of bonds between calcium and pectin in the tissue of the fruit. The higher the concentration of calcium chloride, the higher the number of bonds between calcium pectin, in such a way that the fruit has a stronger tissue structure. Similarly, applying calcium chloride combined with cold storage can maintain the quality of the fresh-cut fruit. However, the application of calcium chloride solution to fresh-cut tropical fruit, especially during the concentration and immersion time is lacking. Based on this, the research on the concentration and duration of immersion of fresh-cut tropical fruit during storage is needed. The purpose of the study was to find out the influence of calcium chloride concentration and the time of immersion in inhibiting the physicochemical changes of fresh-cut tropical fruits.

Research Methods

The fruit used were mangosteen and mango with a picking age of 105 days and rambutan for 120 days. The selected fruits were free from contamination, defects and fresh. The tropical fruits of mangosteen, mango harumanis and rambutan aceh were obtained from Panji village, Sukasada sub-district, Buleleng district, Bali province, Indonesia. The research design used was completely randomized two factors. Furthermore, factor I is the concentration of calcium chloride solution, which consists of 4 levels (0.5%, 1.0%, 1.5%, and 2%). The second factor is the immersion time in the calcium chloride solution, which consists of 3 levels (10, 20, and 30 minutes). The controls were provided for comparison and the study was repeated three times.

The research started with the characterization of the whole tropical fruit including picking age, maturity stage, skin color and visual texture. The mango used as a raw material for fresh-cut is the Harumanis mango with the criteria of maturity stage, namely dark green and dusty skin color, raised shoulders, curved stalks, rounded apices, sweet scent, yellow-orange flesh, more dirt levels lower than 15%, weight 350-600 g. The mangosteen used is a fruit with maturity stage, namely greenish yellow skin color with 50% pink spots spreading on the fruit skin, round like a pressed ball, fruit flesh consisting of 5-8 segments, fresh green petals and fruit weight 130 -180g. The rambutan fruit, which is used as a fresh-cut raw material is Aceh variety fruit with the criteria of evenly red skin maturity stage, round or oval fruit, long fruit hair, transparent white flesh, fruit weight 20-30g.Before the fruits are processed, they are at least pre-cooled using the hydrocooling method and then drained. The tropical fruits of mango, mangosteen, and rambutan are then minimally processed by peeling and removing the skin and seeds, and a stainless steel knife was used for stripping. Furthermore, the mangoes are cut into cubes 4x4x1.5 cm (without seeds), while the mangosteen fruit remains in the form of unified segments. Similarly, the rambutan fruit was prepared without skin, but the seeds were left alone.

Then, the fresh-cut mango, mangosteen and rambutan were immersed in a calcium chloride solution with different concentrations and immersion time. In addition, the fresh-cut fruit was drained and dried for 20 minutes, then packed in a plastic box equipped with 2 holes with a diameter of 0.5 cm on the lid. The fresh-cut fruits were stored in the chiller at a temperature of 7 ± 1°C and is regularly observed on day 0, 3, 6, and 9. The observed variables are pH, moisture content, total solids dissolved, weight loss, texture, and browning index. The data obtained was tested statistically using analysis of variability. If the diversity shows a significant effect due to the treatment, then the test is continued with Duncan's Multiple Range Test to determine the real difference in the mean data from the treatment.

Results

The degree of acidity or pH is an important parameter that determines the success of the subsequent coating process. The treatment of the calcium chloride concentration and the immersion time of the solution as well as their interaction influenced the pH of fresh-cut mangoes and rambutan during storage day 3, 6, 9, while mangosteen and fresh-cut mango only had an effect on day 3. The fresh-cut mango tends to increase pH during storage, mangosteen is relatively stable, while rambutan tends to decrease. The pH value of the fresh-cut mango ranges from 3.80-5.11, mangosteen 2.95-3.50 and rambutan 2.25-4.41.The moisture content is an essential factor that affects fruit quality, which is associated with toughness [11]. The results showed that the concentration of Calcium chloride, the duration of immersion and its interaction affected the fresh-cut mango moisture content only on the 9th day, while mangosteen and rambutan are affected on the 3rd, 6th, and 9th days respectively. The fresh-cut mango moisture content ranges from 72.14-82.26%, mangosteen 78.85-83.91% and rambutan 76.98-84,16%.

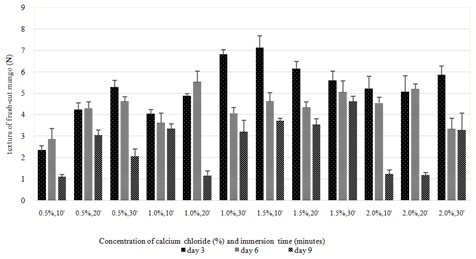

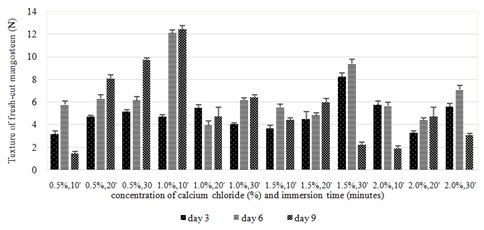

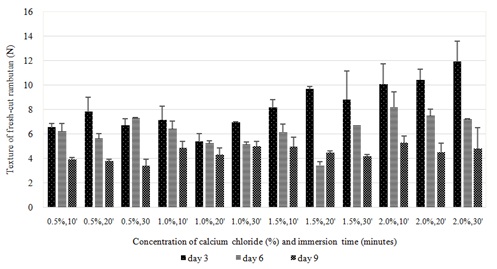

The treatment of calcium chloride concentration and immersion time and its interactions affected the total dissolved solids of fresh-cut mango, mangosteen and rambutan (days 3, 6, 9). The total dissolved solids of fresh-cut mango were between 20.00-25.00°brix, mangosteen 21.00-25.30°brix and rambutan 19.70-25.00°brix. The total dissolved solids in all the three types of fresh-cut fruit increased until the 6th day of storage then decreased, except for mangoes. The treatment of Calcium chloride concentration, immersion time and its interaction affected the weight loss of fresh-cut mango, mangosteen and rambutan during storage processes (days 3, 6, 9). The treatment of chloride leads to an increase in weight loss up to day 6 and decreased on day 9.Texture is an essential characteristic of high quality of fresh-cut products. The results showed that the treatment of calcium chloride concentration and the duration of immersion and its interaction had an effect on the fresh-cut texture of mangoes, mangosteen and rambutan during storage day 3, 6, and 9, and then decreased (Figures 1-3).

Figure 1: Texture of fresh-cut mango.

Figure 1: Texture of fresh-cut mango.

Figure 2: Texture of fresh-cut mangosteen.

Figure 2: Texture of fresh-cut mangosteen.

Figure 3: Texture of fresh-cut rambutan.

Figure 3: Texture of fresh-cut rambutan.

Enzymatic browning is one of the main causes of the deterioration in the quality of fresh-cut products [12]. Browning is mainly based on the oxidation of phenolic compounds by the enzyme Polyphenol Oxidase (PPO), with the quinone compounds polymerizing to brown, reddish or black melanins [13]. The results showed that the treatment of calcium chloride concentration and the duration of immersion and its interaction affected the fresh-cut browning index of mango and rambutan (days 3, 6, 9). The more calcium chloride concentration was added, the lower the browning index of mangosteen and rambutan, but this was not the same in the case with mangos. This is because the mango is sliced in such a way that the surface of the fruit is more hydrophilic.

Discussion

Degree of acidity (pH)

The calcium concentration leads to different pH reactions in fresh-cut tropical fruits. The increase in the concentration of calcium chloride also leads to an increase in the pH of fresh-cut mangoes and rambutan. The Changes in pH indicate a change in the strength of the sugar as the fruit ripens, except that this is due to a decrease in total acidity, which is used as a substrate for the respiratory process [14]. The longer immersion time of fresh-cut tropical fruit in the calcium chloride solution leads to a higher pH. The process of increasing and decreasing pH depends on the level of the total acid content in the fruit, the higher the total acid value, the lower the pH value. The decrease in pH in fresh-cut mangosteen is due to the breakdown of sugar into organic acids [15]. Likewise, according to [2], the acidity of fruits is highest during growth and development and then decreases during storage.

Moisture content

The moisture content was sufficiently high in the 1% calcium chloride treatment with a weekly period of 10 minutes for all three types of fresh-cut fruit. This means that by the treatment of calcium chloride, the fresh moisture content of tropical fruits can be retained during storage. According to [11], calcium can strengthen cell structure. Furthermore, calcium ions can affect the hardness by increasing the integrity of the membrane in such a way that the cell turgor pressure increases. Meanwhile, in line with [16], calcium ions form bonds with the carbonyl of galacturonic acid in such a way that a cross-bonding occur to help dissolve the pectin formed, then the water remains in the network. Applying calcium to fresh-cut fruit helps maintain the integrity of the textured tissue membrane, increasing cell turgor and extending shelf life.

Total dissolved solids

The increase in calcium chloride concentration led to an increase in the total dissolved solids of fresh-cut tropical fruit. This is because more and more calcium ions bind to the pectic acid of the fruit to form Ca-pectate, which inhibits the respiration process and promotes sugars into organic acids. Meanwhile, the increase in immersion time caused a decrease in total dissolved solids, due to the increasing number of sugar components dissolving in the calcium chloride solution [17], reported that total dissolved solids inhibited the decrease in ascorbic acid and had a positive effect on the protection of the oxidation process, which extend the shelf life. Furthermore, immersion fresh-cut fruit in calcium chloride can increase the calcium content in the tissue, which in turn can inhibit the respiration rate of the fruit. The slow rate of respiration causes the slow conversion of starch to glucose [2]. The total dissolved solids content increases during the storage process, this occurs when the fruit ripens process continue to decrease during storage.The increase in glucose levels is due to the hydrolysis of starch to glucose. At the end of storage, there is a decrease in glucose levels, possibly due to reduced starch hydrolysis, while the glucose is used as a respiratory material that continues during the storage process. According to [18], when starch is hydrolyzed and forms glucose, it leads to an increase in glucose levels in the fruit, while a decrease in the fruit glucose levels occurs because glucose is used as the basic material for the respiration process.

Weight loss

The researchers also reported that storage time is closely related to fruit weight and sugar content [18]. The weight loss in fresh fruit and vegetables is caused by water loss [19]. The administration of calcium chloride with high concentrations can reduce weight loss of fresh-cut mangosteen and rambutan fruit, this is due to the interaction of calcium with pectin on the walls, which can limit water loss. The addition of calcium result in rigidity in the cell wall, and the binding of calcium by pectic acid forms Ca-pectate, which can reduce water permeability on cell membranes, thereby reducing the rate of respiration, transpiration and inhibiting fruit weight loss [20]. Applying calcium to fresh-cut mangoes in high concentrations result in greater weight loss. This is because the mango slices have a wider surface area and are very hydrophilic. The increase in weight loss occurs because during the storage and ripening process, the fruit continues to carry out the metabolic processes of respiration and transpiration, which can lead to the loss of water and other organic matter. Furthermore [9], stated that plant tissue is in equilibrium with the atmosphere at the same temperature. Fresh-cut products are more prone to water loss as internal tissue is exposed to skin and cuticle loss. The water in the intercellular space of the intact fruit is not exposed directly to the outside, but is fresh-cut by cutting the exposed inner tissue and greatly increasing the rate of evaporation. This is in line with the statement of [20], that weight loss occurs after the product is harvested and the weight loss rate depends on the surface area of the product and environmental conditions. Increasing the immersion time in calcium chloride solution resulted in increased fruit weight loss. This is because immersion in calcium causes several other components to dissolve, resulting in greater weight loss [18].

Texture

The production of fresh-cut mango by means of a cutting process with a size of 4 x 4 x 1.5 cm causes the surface area to experience a larger wound and is very hydrophilic in such a way that the adhesion of calcium chloride on the fruit surface is weak. The texture of fresh-cut rambutan also increases only until the 3rd day, because the surface of the rambutan fruit is slippery in such a way that the adhesion is low. Meanwhile, the texture of fresh-cut mangosteen increased until the 6th day and after that it decreased, meaning that calcium chloride was more effective in increasing the fresh-cut texture of mangosteen fruit compared to mangoes and rambutan.The longer the immersion, the more likely it is for calcium to penetrate the tissue and greatly increase the fresh-cut texture of tropical fruits. The treatment of calcium chloride at a higher concentration showed that calcium accumulates in the fresh-cut fruit, which greatly increases the hardness of the fruit. The interaction between calcium and pectin on the fresh-cut cell wall of the fruit is characterized by cross-linking between pectates and polysaccharides with divalent calcium ions. This bonding can inhibit softening in such a way that the texture can be maintained. According to the research performed by [21], immersion tomatoes with a concentration of 6% texture is higher than the control. The same was stated by [22], that there was a positive relationship between calcium concentration and fruit texture, which was seen by increasing the texture of apples due to the provision of 4% calcium [10], reported that Ca treatment can maintain the texture of 5.33 N strawberries during 17 days of storage.According to [23], Ca2 + can maintain and improve the integrity and mechanical properties of the cell walls and inhibit fruit softening.

The texture of fresh-cut fruit tends to decrease in all treatments during the storage process. Several previous studies stated that this decrease was caused by cell wall degradation [24]. The softening of the fruit is one of the undesirable changes during storage [25], stated that the decrease in the hardness level of stored fruit was caused by the degradation of hemicellulose and pectin into water-soluble pectic acid. The pectin in fruit is a component of the cell wall and middle lamella, which affects the hardness of the fruit. According to [2], structures such as the cell wall, middle lamella and cell membrane experience biochemical changes during maturation, which lead to loss of cohesion between cells resulting in a softer and weaker structure. One of the main polysaccharide cell walls of pectin plays an important role in maintaining fruit texture [26]. Pectin is a complex heteropolysaccharide, consisting of homogalacturonan, and rhamnogalacturonan [27]. Furthermore, softening is mainly caused by pectinolytic and proteolytic enzymes due to the damage on the fruit tissue cell walls during mechanical operation. This enzyme affects the morphology, structure of the middle lamellae of the cell wall, cell turgor, moisture content and biochemical components. Meanwhile, pectinase enzymes such as pectin methyl esterase hydrolyze pectin methyl ester bonds to produce pectic acid and methanol. Polygalacturonate which hydrolyzes ?1-4 glucoside bonds from anhydro galacturonic acid units causes texture degradation due to pectin polymer hydrolysis. Thus, calcium treatment can inhibit fresh-cut softening [28].

Browning index

The cutting causes mechanical damage that removes the natural protection of the epidermis and destroys the internal compartment that separates the enzymes from the substrate, there by accelerating the browning process [4,29]. The increase in the immersion time of fresh-cut resulted in a decrease in the browning index of mangosteen and rambutan, while that of mango increased. Many fruits contains phenolic compounds, which includes tropical fruits. After cutting the surface of the fruit, it turns brown very quickly. This change has a significant effect on the visual impact, such as reducing consumer acceptance, marketing, and reducing the nutritional value of the product [4].

The fresh-cut browning index of the mango and rambutan increased until the 6th day, then decreased again, while in the mangosteen fresh-cut the decline continued until the 9th day. The browning index reported in mangoes is higher than that of mangosteen and rambutan. The browning index increased due to the degradation of vitamin C, maillard reactions and oxidation of anthraquinone. The fruits have living tissue in such a way that an enzymatic browning process occurs and reduces the shelf life [2]. The injury also induces the synthesis of several enzymes involved in the browning reaction or the synthesis of phenolic compounds by the Phenyl Alanine Amonialiase (PAL) enzyme which can then be oxidized by Polyphenol Oxidase (PPO), producing a brown polymer that contributes to browning of commodity tissue. Subsequently, PPO oxidizes flavonoids and chlorogenic acid into brown compounds [9,30,31].

Conclusion

The results showed that a coating of calcium chloride with a concentration of 1% and immersion time of 10 minutes was the best on the effect of calcium chloride concentration and immersion time on fresh-cut mango, mangosteen and rambutan. Furthermore, it is based on the fact that flesh-cut mango, mangosteen and rambutan have a good appearance during the treatment processes, the vitamin C content, moisture content and texture are quite high, and the weight loss and browning index are low. This formulation has the potential to inhibit the physicochemical changesof fresh-cut mangoes and rambutan for 6 days and mangosteen for 9 days.

Acknowledgement

The authors are grateful to Rector of Warmadewa University, for supporting the project and also to all colleagues that have assisted in this project.

References

- Vargas M, PastorC, Chiralt A, McClements DJ, Inez CG (2008) Recent advances in edible coatings for fresh and minimally processed fruits. Crit Rev Food Sci Nutr 46: 496-551.

- Olivas GI, Barbosa-Cánovas GV (2007) Edible coatings for fresh-cut fruits. Crit Rev Food Sci Nutr 45: 657-670.

- Galgano F, Condelli N, Favati F, DiBianco V, Perretti G, et al. (2015) Biodegradeable packaging and edible coating for fresh-cut fruits and vegetables. Italian Journal of Food Science 27: 1-20.

- Artes F, Allende A (2014) Emerging Technologies for Food Processing. Elsevier Science, Amsterdam, Netherlands.

- SirichoteA, Jongpanyalert B, Srisuwan L, Chanthachum S, Pisuchpen S, et al. (2008) Effects of minimal processing on the respiration rate and quality of rambutan cv. ‘Rong-Rien’. Songklanakarin J Sci Technol 30: 57-63.

- Alikhani M (2014) Enhancing safety and shelf life of fresh-cut mango by application of edible coatings and microencapsulation technique. Food Sci Nutr 2: 210-217.

- Robles-Sánchez RM, Rojas-Graü MA, Odriozola-Serrano I, González-Aguilar G, Martin-Belloso O (2013)Influence of alginate-based edible coating as carrier of antibrowning agents on bioactive compounds and antioxidant activity in fresh-cut Kent mangoes. LWT-Food Science and Technology 50: 240-246.

- Tappi S, Ragni L, Tylewicz U, Romani S, Ramazzina I, et al. (2017)Browning response of fresh-cut apples of different cultivars to cold gas plasma treatment. Journal of Innovative Food Science & Emerging Technologies 53: 56-62.

- Siddiqui W, Chakraborty I, Ayala-Zavala JF, Dhua RS (2011) Advances in minimal processing of fruit and vagetables: A review. Journal of Scientific & Industrial Research 70: 823-834.

- GaniA, Baba WN, Ahmad M, Shah U, Khan AA, et al. (2016) Effect of ultrasound treatment on physico-chemical, nutraceutical and microbial quality of strawberry. LWT-Food Science and Technology 66: 496-502.

- Fundo JF, Galvis-Sanchez A, Madureira AC, Carvalho A, Feio G, et al. (2016) NMR water transverse relaxation time approach to understand storage stability of fresh-cut ‘Rocha’ pear. LWT 74: 280-285.

- Tinello F, Lante A (2018) Recent advances in controlling polyphenol oxidase activity of fruit and vegetable products. Innovative Food Science and Emerging Technologies 50: 73-83.

- KasimR, Kasim MU (2015) Biochemical changes and color properties of fresh-cut green bean (Phaseolus vulgaris L. gina) treated with calcium chloride during storage. Food Sci Technol 35: 266-272.

- Zheng X, Ye L, Jiang T, Jing G, Li J (2012) Limiting the deterioration of mango fruit during storage at room temperature by oxalate treatment. Food Chemistry 130: 279-285.

- Tadesse, Abtew WG (2016) Effect of hot water treatment on reduction of chilling injury and keeping quality in tomato (Solanum lycopersicum) fruits. Journal Stored Products and Postharvest Research 7: 61-68.

- Zhi H, Liu Q, Xu J, Dong Y, Liu M, et al. (2017) Ultrasound enhances calcium absorption of jujube fruit by regulating the cellular calcium distribution and metabolism of cell wall polysaccharides. J Sci Food Agric 97: 5205-5210.

- Sobral MMC, Nunes C, Maia A, Ferreira P, Coimbra MA (2017) Conditions for producing long shelf-life fruit salads processed using mild pasteurization. LWT-Food Science and Technology 85: 316-323.

- GeyaY, Kimura T, Fujisaki H, Terada Y, Kose K, et al. (2013) Longitudinal NMR parameter measurements of Japanese pear fruit during the growing process using a mobile magnetic resonance imaging system. J Magn Reson 226: 45-51.

- Cárcel JA, Benedito J, Rosselló C, Mulet A (2007) Influence of ultrasound intensity on mass transfer in apple immersed in a sucrose solution. Journal Food Engineering 78: 472-479.

- Khaliq G, Mahmud TM, Ali A, Ding P, Ghaali HM (2015) Effect of gum arabic coating combined with calcium chloride on phsyco-chemical and qualitative properties of mango (Mangivera indica L) fruit during low temperature storage. Scientia Horticulturae 190: 187-194.

- Genanew T (2013) Effect of postharvest treatment on storage behavior and quality of tomato of fruit. World Journal of Agricultural Science 9: 29-37.

- Tunckal C, Alibas K (2012) Effect of calcium concentration and vacuum pressure on pulp hardness and Ca quantity of post harvest 'Golden Delicious' apples. Journal Agricultural Machinery Science 8: 441-449.

- Sogvar BS, Saba MK, Emamifar A (2016) Aloe vera and ascorbic acid coatings maintain postharvest quality and reduce microbial load of strawberry fruit. Postharvest Biology and Technology114: 29-35.

- LiuX, Ren J, Zhu Y, Han W, Xuan H, et al. (2016) The preservation effect of ascorbic acid and calcium chloride modified chitosan coating on fresh-cut apples at room temperature.Colloids Surf A: Physicochem Eng Asp 502: 102-106.

- Moggia C, Graell J, Lara I, González G, Lobos GA (2017) Firmness at harvest impacts postharvest fruit softening and internal browning development in mechanically damaged and non-damaged highbush blueberries (Vaccinium Corymbosum L.). Frontiers in Plant Science 8: 1-11.

- Zhang L, Zhao S, Lai S, Chen F, Yang H (2018) Combine effect of ultrasound and calcium on the chelate-soluble pectin and quality of stawberries during storage. Carbohidrate Polymer 200: 427-435.

- Ferreira SS, Passos CP, Madureira P, Vilanova M, Coimbra MA (2015) Structure-function relationships of immunostimulatory polysaccharides: A review. Carbohydrate Polymers 132: 378-396.

- Yang H (2014) Atomic force microscopy (AFM): Principles, modes of operation and limitations. Nova Science Publishers, Incorporated, New York, USA.

- Suriati L, Utama IMS, Harsojuwono BA, Gunam IBW (2020) Ecogel incorporated with nano-additives to increase shelf-life of fresh-cut mango. Journal of Applied Horticulture 22: 189-195.

- Suriati L (2018) Studies the Resistance to Oxidation and the Changes Phases against the Characteristics of Physicochemical Aloe vera Gel. Journal of Biological and Chemical Research 35: 670-679.

- Suriati L, Utama IMS, Harsojuwono BA, Gunam IBW (2020) Incorporating additives for stability of aloe gel potentially as an edible coating, Journal AIMS Agriculture and Food 5: 327-336.

Citation: Suriati L, Utama IS, Harsojuwono BA, Gunam IBW, Adnyana I (2021) Differences in Physicochemical Characters of Fresh-Cut Mango, Mangosteen and Rambutan Due to Calcium Chloride Application. J Food Sci Nutr 7: 107.

Copyright: © 2021 Luh Suriati, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.