Functional Valorization and Shelf-Life Extension of Rice Bran Using Heat-Based Stabilization Methods

*Corresponding Author(s):

Supriya PriyadarsaniICAR-National Rice Research Institute, Cuttack, India

Email:Priyanka222bharti@gmail.com

Abstract

Rice bran deteriorates quickly which restricts its’ full potential use of this very nutritious food that has numerous health benefits due to its bioactive components. The primary barrier to use rice bran as food is hydrolytic rancidity, which can only be avoided via enzyme inactivation. This study was conducted at NRRI, Cuttack on rice bran of rice variety CR Dhan 310. It determined that thermal solution can enhance the stabilization of enzyme inactivation and functional properties of rice bran. Four thermal stability measures microwave, convection, steaming and solar were used to stabilize rice bran. Treatments effect on rice bran physicochemical and functional properties was examined and compared after 9 days. A progressive result in FAA (P<0.05) was found when the rice bran sample was microwave treated (at 500W for 5min) and then by steaming (for 20min). Other values like protein content, remain more intact in thermal treated samples compared to untreated samples whereas γ-oryzanol, was found to slightly decrease due to heat treatments. Physico-chemical and functional properties like fat content, moisture content, bulk density, colour value (L*, a*, b*), WAC, WAI, WSI, OAC, SP, EA, ES, FC, FS were recorded significant (p < 0.05) for thermal treated samples. Among the result studied under various thermal treatments, PCA analysis also confirmed that microwave treatment followed by steaming, reflected a better result for stabilization of the rice bran.

Keywords

FFA; Heat treatment; Microwave; PCA; Rice bran; Stabilization

Introduction

Rice bran is the brown outer layer of the rice grain, which is produced as a by-product during the milling of paddy [1]. Rice bran is rich in many nutrients, including γ-oryzanol, oil-18%, protein-15% and carbohydrates 50% [2]. Research findings by Zakir et al. [3], and Irakli et al. [4], state that γ-oryzanol in rice bran act as a strong antioxidant, which prevent oxidative damage of cellular protein. It also supports cardiovascular health, lower cholesterol, and exhibits anti-inflammatory and antimicrobial effect [5]. Additionally, rice bran is gluten free and rich in dietary fibers, leading to its increasing usage in food production industry for making food products like breads, cakes, and ice cream, without altering its sensory and textural characteristics [6].

Though being healthy, the lipid fraction of rice bran presents a significant challenge to its utilization. The high fat content predisposes rice bran to rapid rancidity, primarily due to due to enzymatic release of Free Fatty Acids (FFA). According to [7,8], rice bran with FFA levels exceeding 10% is considered unfit for human consumption, whereas level below 5% are considered suitable. This instability necessities timely and effective stabilization to preserve rice bran’s nutritional integrity and extent its shelf life.

Stabilization done rightly deactivates enzymes and conserves nutrients at their highest level. It deactivates lipolytic enzyme, particularly lipase, and curb FFA accumulation. Thermal treatments are the most popular technique for stabilization, with temperatures above 120oC causes oxidation of rice bran to be denatured, but they have no effect on nutritional value of rice bran. Majority of methods use either dry air or moist thermal treatment have yield satisfactory result. The right way to stabilize depends on how much moisture the bran has, how long we treat it, and at what temperature [8]. According to Patil et al. [9], lipase activity slows down when rice bran samples was microwaved for three minutes. It also studied that reduction of FFA rice bran can be achieved by microwave treatment, which was run at 4W/g for 5 minutes.

As sustainable valorization interest is growing in agro-industrial by-products, this study investigates the comparative effectiveness of stabilization methods, microwave heating, convection, steaming, and solar drying, of rice bran. It evaluates their impact by elucidating the interplay between treatment paraments and stabilization outcomes, for contributing in development of rice bran valorization in food industries.

Materials and Methods

Stabilization Treatment

The study was conducted at National Rice Research Institute (NRRI), Cuttack on rice bran of rice variety CR Dhan 310 collected from National Rice Research Institute (NRRI) farm. Rice was milled to get its rice bran which was stabilization using different heating methods. One portion of rice bran was kept untreated (control) and the rest treated with four different methods (Microwave, convection, steaming and solar drying) were used for stabilization. Microwave heating was performed at 500W for 5min, convection method was applied at 80oC for 5min, steaming was performed in autoclave for 20min and solar drying for (8h per day) at 42oC for 3 days. The stabilized samples were stored for 9 days at 4oC then stability of the samples were tested.

Proximate Analysis

Moisture content was determined using standard oven method [10]. 5g of rice bran weighed in ceramic cubicles and was dried in oven for 103±2oC for 2h to get the moisture free samples. Fat content was recorded from stabilized rice bran using soxhlet apparatus. 6g of sample was taken in the thimble and extracted for 3h using n-hexane [11]. Protein content was determined using Kjendhel method (N x 5.95, wet basis) [10].

Bulk Density

It was determined by filling a graduated cylinder with stabilized rice bran which was compacted by light tapping. Its volume and mass were recorded to calculate bulk density.

Colour Measurement

Colour value (L*, a*, b*) was recorded using Hunter lab calorimeter as per standard procedure [10].

Free Fatty Acid Content

Free fatty acid was determined by titrating 2g sample in alcoholic medium with 0.05 N NaOH [10]. Titrated value was used to calculate FFA%.

FFA % = (titrated value x Normality of NaoH x 28.2)/wt.of sample

Quantifying γ-Oryzanol Using RP-HPLC

RP-HPLC was used to quantify γ-oryzanol in accordance with the approach described by Castanho et al. [12]. Samples were prepared by using n-hexane and Isopropanol. A reverse phase C18 column was operated in isocratic mode with mobile phase consisting of methanol, acetonitrile, acetic acid and dichloromethane in the ratio of 50:44:3:3. Then, γ-oryzanol compounds identification was done at 325nm wavelength.

Hydration Properties

WAC was carried out in accordance to Rao et al. [13], 5g of stabilized RB was suspended in 30ml of water and stirred for 2-3 times at an interval of 10min. the mixture was then centrifuged at 2300rpm for 25min. The residue left was dried and the weight of sample recorded after centrifuge and after drying was used to calculate WAC per g of sample, WAI and WSI.

Formula used were,

Water absorption capacity = (wt. of the sample after centrifuge - wt. of the sample after drying)

Water absorption index = [(wt.of sample after centrifuged)/(wt.of sample taken) ] x 100

Water solubility index = [(wt.of dissolved solid)/(wt.of sample after drying) ] x 100

where,

wt. of dissolved solid = wt. of the sample taken- wt. of sample after drying

Oil Absorption Capacity (OAC)

In order to perform OAC, 5g of stabilized rice bran was suspended in 30ml of soybean oil and agitated two to three times at 10min intervals. Then the mixture was centrifuged for 25min at 2300rpm. After centrifuging and drying the residue, the difference between the sample wt. after centrifugation to sample wt. after drying was recorded as OAC.

Swelling Power (SP)

The swelling power was evaluated using the procedure reported by Waliszewski et al. [14], with minor changes. 9ml of water and 0.5g of stabilized rice bran sample were combined to create slurry, which was vortexed for 30s (w1). The suspension was cooked for 30min at 70oC in water bath while being constantly stirred. After allowing the mixture to reach room temperature, it was centrifuged for 15min at 2000x g to get precipitation (w2). Then following formula was used to determine the swelling power:

Swelling power = (w1 - w2 ) / wt.of sample

Emulsifying Properties

After adding 10ml of soybean oil to stabilized rice bran sample solutions (1% w/v), the mixture was homogenized for one minute at 10000 rpm. The following formulas were used to determine the emulsifying activity and stability:

Emulsifying activity = [A/B] x 100

Emulsifying stability = [ Aincubate / A x 100 ]

Where,

The emulsion layer`s volume is A, the overall volume represents B, and the emulsion layer`s volume at 10minutes incubated at 80oC is Aincubate,.

Foaming Properties

The foaming capacity of Stabilized rice bran samples were assessed by measuring homogenization of (1% w/v, 20mL) at 1000rpm for one minute. The entire volume was determined at zero and sixty minutes after whipping. The following formulas were used to determine foaming activity and stability:

Foaming capacity = [(A-B)/B] x 100

Foam stability = [(A60min-B)/A0min-B] x 100

Where,

The volume following whipping is A (ml)

The volume prior to whipping is B (ml)

Statistical Analysis

Statistical data were analyzed using (Minitab statistical software vs. 19.1.1). The evaluation used was ANOVA and significance level of (P<0.05). PCA was performed in OriginPro, Version 2024, USA.

Result And Discussion

Effect on Proximate Composition, Bulk Density and Colour Value

Composition of heat-treated rice bran samples was recorded after 9 days following the standard procedure. Moisture content, protein content, fats content, bulk density and colour was calculated and compared between heat treated and control rice bran samples. Moisture content of treated rice bran ranged from 7.34-10.69 %, (wb) and control sample was 10%, where treated samples moisture content was lesser than the control, except in case of steaming. Higher moisture content was observed in steaming due to absorption of water vapour. Among the heat-treated samples solar, microwave and convection treatment showed a significant (P < 0.05) decrease in moisture content. Low moisture content signifies higher stability of product due to low water activity [3,15].

Protein content for heat treated varied from 12.1-12.8%, (wb). Slight increase in microwave was observed due to the denaturation and aggregation of protein due to dielectric heating. The aggregation and made protein more exchangeable and measurable resulted in slight increase in the protein content. Similar finding was observed by Lv et al. [16], and Kusumawaty et al. [17], when rice bran was stabilized by heat treatment which resulted in rise of protein content. Fat content was recorded to vary between 15.7-14.8% for the treated samples, were as, 16.5% was observed in case of untreated sample, as highlighted in the prior studies made by [3,15].

In case of Bulk density heat treated rice bran was more or less similar to control sample from (0.4-0.5g/ml). There was no significant change observed in bulk density when rice bran was thermally treated because the physical structure of the bran particles remained largely unaffected by heating process. Heat treatment primarily impacts the chemical composition and nutritional quality of rice bran without altering its bulk density significantly [4].

Colour (L*, a* and b*) value of the samples was (51.5-57.5, 4.5- 6.2, 22.1-25.3) that showed significant value of P < 0.05. It was observed that heat treated rice bran samples showed little darker in colour with respect to control sample. The change in the colour of heat-treated samples was mainly due to the maillard reaction and browning reaction caused due to oxidation of proteins and sugar when exposed to thermal treatment. All these reactions caused formation of melanoidins, which contributed to forming brown pigments making rice bran darker [3,15].

Effect on Free Fatty Acid

Free fatty acids are one of the major causes of rancidity in the rice bran samples. High FFA content demonstrates poor storage, inadequate processing, high moisture content and more importantly lipase enzyme activity [4,13,18]. Thus, FFA content made a good parameter for determining the stability of the rice. From table 1, microwave stabilized rice bran recorded lowest FFA content of 3.3% which was 65% lower than the untreated sample (9.5%). Rapid heating and short processing time during the microwave treatment inactivated the lipase enzyme and reduced the formation of FFA in rice bran sample. Thereafter, steaming with 3.5%, convection with 5.9%, solar with 8.2% and control at 9.5% FFA was recorded. Irakli et al. [4], recorded similar trend while stabilizing rice bran by heat treatments, microwave heating gave a significant decrease (p < 0.05) in FFA content with mean value of 5.53%. Reis et al. [15], Kim et al. [19], and Amarasinghe et al. [20], analyzed similar effect on rice bran and rice bran oil both resulted that, thermal treated lowered the percentage of FFA.

|

Sample |

WAC(g/g) |

OAC (g/g) |

WAI(g/g) |

WSI (%) |

SP (g/g) |

FFA(%) |

Υ-Oryzanol (mg/g) |

|

Control |

2.18±0.1e |

1.29±0.5a |

5.05±0.7a |

21±1.1e |

4.83±0.6e |

9.5±1.2a |

3.01±0.8a |

|

Microwave |

3.34±0.2a |

1.45±0.8a |

3.75±1.1d |

28±0.2a |

7.01±1.1a |

3.3±1.3d |

2.04±0.6b |

|

Convection |

2.87±1.1c |

1.32±0.3a |

4.46±0.9b |

23.5±0.8c |

5.88±1.7c |

5.9±0.6c |

2.01±0.7b |

|

Steaming |

3.16±1.5b |

1.36±0.7a |

4.05±0.6c |

25±1.6b |

6.06±1.7b |

3.5±1.8d |

1.02±0.8c |

|

Solar |

2.67±0.3d |

1.01±0.7b |

4.51±0.9b |

22.5±1.5d |

5.12±1.9d |

8.2±1.3b |

2.01±1.1b |

Table 1: Functional properties of thermal treated rice bran samples.

Effect on γ-Oryzanol (GO) Content

The γ-Oryzanol (GO) content in rice bran samples was assessed using HPLC technique and was compared to standard γ-Oryzanol. The level of GO varied between 1-2mg/g for all the samples subjected to heat (Table 1). All heat treatment showed same result of 2mg/g except steaming, having the lowest GO retention of 1mg/g. Heating at high temperature for longer time reduces the GO content of rice bran thus, all the heat treated reported reduced GO content. The steaming used both heat as well as steam resulted in further reduction in GO content. Whereas, untreated sample had highest retention of γ-Oryzanol, amounting 3mg/g. Zakir et al. [3], Irakli et al. [4], and Lakkakula et al. [21], found similar reduction in γ-Oryzanol when thermal treatment was given to rice bran and rice bran oil.

Effect on Functional Attributes

Rice bran samples are hygroscopic in nature thus, which enhances its water retention capacity. The WAC of samples varied between 2.18-3.34g/g. There was considerable rise in WAC in all heat-treated samples (Table 1), among them microwave showed the highest water absorption capacity of 3.34g/g. It was due to decrease in moisture content before providing a spatial opening for water retention. Pratama and Parwiyanti [22], also found significant increase in WAC when treated with dry-thermal treatment. Rice bran samples WAC fell considerably under (P < 0.05) following all stabilization treatments.

WAI of all the rice bran samples resulted from 3.75-5.05g/g while being significant under P < 0.05. Microwave stabilized rice bran reflected lowest WAI (3.75g/g), then all untreated and treated samples, as microwave treatment distributed moisture more evenly throughout the sample and reduced the rice brans’ likeness to create highly absorbent region [4].

WSI determined the consistency of rice bran ensuring maintenance of its quality during storage, which ranged from 21-28%. Significant increase in WSI was observed for all heat-treated samples depicting better rice bran storage quality. The microwave heat treated samples with 28% showed better result as treatment resulted in simpler and more soluble fragments due to rapid heating by dielectric movements of charges and disrupting the cellular structure, making rice bran quality better for storage for longer period Irakli et al. [4], shared similar result when rice bran was stabilized by microwave and dry air.

OAC was lowest 1.01g/g in case of solar stabilization of rice bran and highest 1.45g/g for microwave treated rice bran. Solar stabilized rice bran showed lower OAC than all untreated and treated samples because cross linkage of molecules made it harder to absorb oil whereas microwave displayed significant (P<0.05) rise in OAC as a result of improved liquid-protein interactions. Lv et al. [16], and Khan et al. [23], also studied stabilization of rice bran including dry heating and microwave methods which resulted in improved OAC of rice bran protein.

SP determines swelling property determining its ability to swell when comes in contact with water, which was investigated to vary between 4.83-7.01g/g. There was significant (P < 0.05) rise in SP was recorded for all heat-treated samples. Microwave stabilization with 7.01g/g had highest value as microwave heating creates rapid in heating of rice bran by dielectric movement which reduces the chances to form cross linkage of cellular structure. So, microwave stabilized rice bran sample had higher retention ability to swell, similar study was conducted on rice bran by Li et al. [24], and Irakli et al. [4], which stated improved SP and its textural characteristics.

Effect on Emulsifying Properties

Rice bran with good emulsifying characteristics is ideal to be utilized as emulsifiers in food processing. Emulsion formation in rice bran samples is due to its hydrophobic and hydrophilic group [25]. The emulsifying stability of stabilized samples ranged from 12.70-9.21%. Rice bran stabilized with microwave reported highest emulsifying stability and solar exhibited the lowest ES (Figure 1). During microwave heating dielectric interaction of rice bran molecules inactivated the enzymes and improved lipid-protein interaction making it more stable in emulsion form [25].

Figure 1: Effect of stabilization treatment on emulsifying activity and emulsifying stability of rice bran.

Figure 1: Effect of stabilization treatment on emulsifying activity and emulsifying stability of rice bran.

Emulsifying activity in case of microwave was (52.71), convection (50.64), steaming (52.63) and solar (48.23) for heat treated samples. Solar dried sample reported lowest emulsifying activity among all treated sample due to loss of lipophilic groups essential for emulsifying it was due to prolonged exposure of rice bran to sun which led to oxidation and denaturation of lipids and emulsifiers reducing its emulsion activity. On the other hand, other heat-treated samples retained its lipophilic groups giving them high emulsifying stability. In microwave treatment reduction in the treatment time held the rice bran sample from oxidation and reduction of lipophilic groups resulting in better emulsifying activity also studied by Lv et al. [16], when stabilized by microwave treatment.

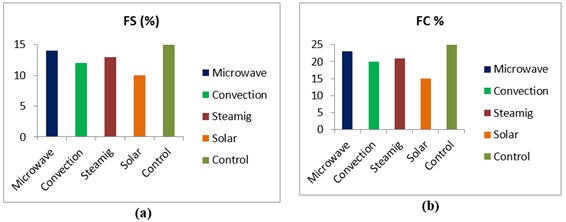

Effect on Foaming Properties

The ability of rice bran to reduce its water and air surface tension is reflected in its foaming properties. It is one of the functional properties exhibited by rice bran making it a prominent use in food processing industry. Foaming capacity for heat treated rice bran samples (Figure 2) ranged between 23-15% where microwave having the highest capacity among heat treated samples. Foaming stability is one of the factors which determine the texture and quality of rice bran where FC value varied from 15-10%.

Figure 2: Effect of stabilization treatment on foaming stability and foaming capacity of rice bran.

Figure 2: Effect of stabilization treatment on foaming stability and foaming capacity of rice bran.

Microwave and steaming reflected highest foaming stability among all thermal treated rice bran samples whereas, lowest was seen in case of solar treated sample. Solar drying generally alters the surface property of sample and also leaves residual moisture in the sample leading to reduction in its foaming stability. Thus, significant decrease in foaming stability was observed in solar drying. Contrary microwave and steaming being faster in nature remove more moisture and preserve natural surface properties creating a better foaming stability Bandyopadhyay et al. [26], also studied thermal treatment on defatted rice bran and found similar result in case of foaming stability.

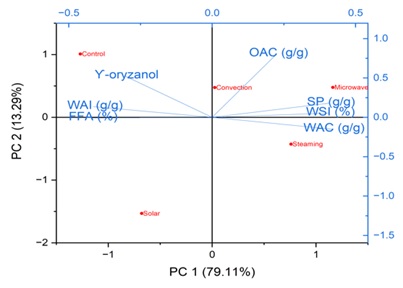

PCA

The stabilization of rice bran through thermal treatments, convection, microwave, steaming, and solar demonstrated distinct impacts on its physicochemical properties, as analyzed by PCA. Principle Component 1 (PC1) accounted for 79.11% of the variance, with PC2 contributed to 13.29% of the dataset (Table 2). From figure 3, microwave treatment exhibited the strongest influence, positioned farthest from the origin, indicating significant enhancement in variables such as γ-oryzanol, WAI, and WSI. Steaming and solar treatment also contributed positively, though to a lesser extent, while convection showed moderate effect to stabilization. The control sample remained near the origin, reflecting minimal alteration. These findings underscore the efficacy of microwave and steaming methods in preserving bioactive compounds and improving functional attributes of stabilized rice bran.

|

PC |

Eigenvalue |

Percentage of Variance |

|

1 |

5.53769 |

79.11% |

|

2 |

0.93001 |

13.29% |

|

3 |

0.51007 |

7.29% |

|

4 |

0.02224 |

0.32% |

Table 2: Principal component analysis of stabilization treatments.

Figure 3: Biplot pattern obtained for stabilization treatments of rice bran.

Figure 3: Biplot pattern obtained for stabilization treatments of rice bran.

Conclusion

The findings indicated that heat-stabilized methods significantly improved rice bran’s shelf-life and functional properties. Microwave heat treatment was more efficient in reducing free fatty acid content by 65%, enhancing water and oil absorption, and preserving protein integrity. All thermal treatments lowered moisture content, contributing to reduce in water activity and improved stability. However, γ-oryzanol retention declined across treatments, with steaming showing the lowest levels due to combined heat and moisture exposure. Microwave treated sample demonstrated high hydration, swelling, emulsifying, and foaming characteristics, making it suitable for diverse food applications. These functional enhancements enable rice bran as a valuable and durable ingredient in bakery, dairy, and health-oriented products. Stabilization by microwave offers an overall sustainable and efficient approach to rice bran valorization and unlock, its nutritional and functional potential while minimizing post-harvest losses and extending shelf-life.

References

- Abdul-Hamid A, Sulaiman RR, Osman A, Saari N (2007) Preliminary study of the chemical composition of rice milling fractions stabilized by microwave heating. Journal of Food Composition Analysis 20: 627-637.

- Nagendra PMN, Sanjay KR, Shravya KM, Vismaya MN, Nanjunda SS (2011) Health benefits of rice bran -a review. Journal of Nutritional and Food Science 3: 1-7.

- Zakir HH, Fahmida N, Alauddin M, Rahman T, Zinnah MA, et al. (2019) Stability-indicating stabilization of rice bran food value by heat treatment. Journal of Nutritional Health and Food Science 7: 1-9.

- Irakli M, Lazaridou A, Biliaderis CG (2021) Comparative evaluation of the nutritional, antinutritional, unctional, and bioactive attributes of rice bran stabilized by different heat treatments. Foods 10: 57.

- Manzoor A, Pandey VK, Dar AH, Fayaz U, Dash KK, et al. (2023) Rice bran: Nutritional, phytochemical, and pharmacological profile and its contribution to human health promotion. Food Chemistry Advances2:

- Lavanya MN, Venkatachalapathy N, Manickavasagan A (2017) Physicochemical characteristics of rice bran. Springer International Publishing Brown Rice 79-90.

- Tao J, Rao R, Liuzzo J (1993) Microwave heating for rice bran stabilization. Journal of Microwave and Power Electromagnetic Energy 28: 156-164.

- Ertürk B, Meral R (2019) The impact of stabilization on functional, molecular and thermal properties of rice bran. Journal of Cereal Science 88: 71-78

- Patil SS, Kar A, Mohapatra D (2016) Stablization of rice bran using microwave: Process optimization and storage studies. Food and Bio Products Processing 99: 204-211.

- AOAC (2000) Official methods of analysis. Association of Official Analytical Chemists. Washington DC, USA.

- Hanmoungjai P, Pyle L, Niranjan K (2000) Extraction of rice bran oil using aqueous media. Journal of Chemical Technology and Biotechnology 75: 348-352.

- Castanho A, Lageiro M, Calhelha RC, Ferreira ICFR, Sokovic M, et al. (2019) Exploiting the bioactive properties of γ-oryzanol from bran of different exotic rice varieties. Food and Function 10: 2382-2389.

- Ramezanzadeh FM, Rao RM, Prinyawiwatkul W, Marshall WE, Windhauser M (2000) Effects of microwave heat, packaging and storage temperature on fatty acid and proximate compositions in rice bran. Journal of Agricultural and Food Chemistry 48: 464-467.

- Waliszewski KN, Aparicio MA, Bello LA, Monroy JA (2003) Changes of banana starch by chemical and physical modification. Carbohydrate Polymers 52: 237-242.

- Reis N, Castanho A, Lageiro M, Pereira C, Brites CM, et al. (2022) Rice bran stabilisation and oil extraction using the microwave-assisted method and its effects on GABA and gamma-oryzanol compounds. Foods 11: 912.

- Lv SW, He LY, Sun LH (2018) Effect of different stabilisation treatments on preparation and functional properties of rice bran proteins. Czech Journal of Food Sciences 36: 57-65.

- Kusumawaty I, Fardiaz D, Andarwulan N, Widowati S, Budijanto S (2014) Isolation and physicochemical properties of rice bran protein from heat stabilized rice bran. Indonesian protein society proceeding of International seminar and workshop on protein. Jember 2014: 29-30.

- Läubli MW, Bruttel PA (1996) Determination of the oxidative stability of fats and oils: Comparison between the active oxygen method and the Rancimat method. Journal of American Oil Chemical Society 63: 792-795.

- Kim S, Chung H, Lim S (2014) Effect of various heat treatments on rancidity and some bioactive compounds of rice bran. Journal of Cereal Science 60: 243-248.

- Amarasinghe BMWPK, Kumarasiri MPM, Gongodavilage NC (2009) Effect of method of stabilization on aqueous extraction of rice bran oil. Food and Bioproducts Processing 87: 108-114.

- Lakkakula NR, Lima M, Walker T (2004) Rice bran stabilization and rice oil extraction using ohmic heating. Bioresource Technology 92: 157-167.

- Pratama F (2018) Impact of dry-and hydro-thermal treatments on swelling power, water solubility on red-rice flours. Agricultural Engineering International: CIGR Journal 20: 227-232.

- Khan HS, Butt MS, Sharif MK, Sameen A, Mumtaz S, et al. (2011) Functional properties of protein isolates extracted from stabilized rice bran by microwave, dry heat, and parboiling. Journal of Agricultural and Food Chemistry 59: 2416-2420.

- Li J, Liu C, Wu N, Tan B (2023) Improvement of gelation properties of indica rice flour with stabilized rice bran from different thermal treatment. Cereal Chemistry 101: 263-273.

- Sogi DS, Chandi GK (2007) Functional properties of rice bran protein concentrates. Journal of Food Engineering 79: 592-597.

- Bandyopadhyay K, Misra G, Ghosh S (2008) Preparation and characterisation of protein hydrolysates from Indian defatted rice bran meal. Journal of Oleo Science 57: 47-52.

Citation: Priyadarsani S, Bharti P, Mohapatra M (2025) Functional Valorization and Shelf-Life Extension of Rice Bran Using Heat-Based Stabilization Methods. HSOA J Food Sci Nutr 11: 224.

Copyright: © 2025 Supriya Priyadarsani, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.