Milk Vending Machine Retail Innovation in Kenyan Urban Markets: Operational Costs, Consumer Perceptions and Milk Quality

*Corresponding Author(s):

Bockline Omedo BebeDepartment Of Animal Sciences, Egerton University, Box 536-20115 Egerton, Kenya

Email:bbebe@egerton.ac.ke

Abstract

Milk retail innovation that assures quality and safety should be attractive to consumers, traders and regulatory authorities in Kenya to address public health and trade concerns in the dairy industry. This study estimated operational cost and retail margin in milk vending machine (ATM) enterprises then compared milk from ATM with packaged milk and milk from plastic containers for consumer perceived risks and preferences, and observed quality. The data was obtained in a survey in five towns through interviews and milk sampling for laboratory quality tests. Results revealed that retail margin per litre of milk is up to US$ 0.1, with average running cost of US$ 102.67 monthly (1US$=100KES), of which more is spent in servicing (58.4%) and paying license fee (24.0%). To consumers, high risk of adulteration, unhygienic handling, bacterial contamination and antibiotic presence is less with ATM milk and packaged milk than with milk from plastic containers. The risk of chemical contaminants present in milk is considered less for milk from ATM and from plastic containers than packaged milk. Consumers have preference for milk from ATM over packaged milk because of price, consistent availability, hygienic premises, and traceability in addition to being free from chemical and biological hazards. Compared to milk from plastic containers, milk from ATM is less prevalent in unsafe bacterial load (<24.0% vs > 68.0%) but more prevalent in presence of antibiotics and hydrogen peroxides (>7.6% vs <4.5%). Milk from ATM and packaged milk are not distinctly different in prevalence of unsafe contaminants. These results demonstrate that ATM is a competitive business for retailing affordable pasteurized milk with safety advantages to consumers. Though consumer accept milk from ATM on perception of being safer than raw milk and as safe as packaged milk, ATM does not guarantee safety and quality. Consequently, the government must prioritise educating dairy value chain actors starting with farmers on value of milk quality and strengthening surveillance, quality control and setting standards for ATM milk retailing.

Keywords

Consumer preferences; Food standards; Hazards; Milk dispensing machine

INTRODUCTION

The Kenya’s Dairy Master Plan being implemented to 2030 outlines the strategies to shift a larger proportion of domestic marketed milk from informal trading of raw milk to formal supply chains trading pasteurised milk [1,2]. This is to address the large proportion of raw milk marketed in the informal retail outlets predominantly using plastic containers. Retailing raw milk in plastic containers offer consumers affordable milk but at the risk of exposing them to health hazards as milk spoilage can be rapid due to difficulties in keeping plastic containers in good hygiene state. Informal milk retailing using plastic containers has raised public health concerns, yet has remained dominant in the domestic market [3,4]. Therefore retail innovations that improve assurance of quality and safety of marketed milk should be attractive in the dairy industry to consumers, traders and regulatory authorities.

The predominant formal milk retailing in Kenya is packaged milk. This pasteurised milk should offer distinct quality advantages to consumers for a premium price that is charged, but it has not sufficiently guaranteed Kenyan consumers quality and safety. Several studies have pointed to prevalent noncompliance with quality standards in milk retailed in both formal and informal outlets in the country [5-8]. Concerns over quality and safety of traded milk are attracting alarming reporting in the media [9,10].

Packaging hikes the retail price of milk, and consumers expressing strong preference for low cost fluid milk may be unwilling to pay or unable to afford the premium price. Milk vending machine, popularly known in Kenya as milk ATM, is an innovation for retailing milk, with automation design to dispense chilled, pasteurised, and ready to drink milk [11]. Automation offers several comparative safety and business opportunities in milk retailing. Automation minimises milk handling, which should enhance hygiene and assure quality and safety to consumers. Automated milk dispensing is a quicker and easier means to measure any volume of milk that a consumer may want. The consumers bring their own containers for the milk, thus avoiding packaging cost and this should lower the milk retail price. All business transactions can be recorded, which to entrepreneurs eases monitoring of business performance. In Kenya, milk ATM are now widespread and are located in strategic retail outlets, at the farms, retail shops, milk bars and supermarkets. This is an indication that ATM is a growing segment of Kenya’s dairy industry even as safety of marketed fluid milk remains a highly debated issue of public concern [4-10].

Regulations require that ATM is cleaned once every 24 hours to assure high quality of milk and minimised loss from spoilage [2]. However, there are indications of noncompliance with quality standards and safety in milk from ATM enterprises. Kosgey et al., [7] tested 80 milk samples from ATM for presence of antibiotics and 24.0% were positive. That study narrowed only on one safety indicator (presence of antibiotics) for milk samples in one town. Therefore our study complements that study by sampling milk from ATM in more towns (five) to test for more indicators of quality and safety in addition to analysing consumer perception of risk associated with milk from ATM and the cost of operation and retail margins. Because of increased local media coverage of poor quality of traded milk [9,10], consumers of chilled and pasteurised, ready to drink milk could have formed opinions about the quality and safety hazards of milk from ATM. Operating milk ATM requires uninterrupted supply of electricity and quality water and regular machine servicing. Failure in these services can compromise quality and safety of the milk, which should concern the vendors, consumers and regulating authorities. The machines are imported and attract several regulatory charges including import tax, licensing fees and permits. The business operational costs if substantial could be a disincentive to practicing the high hygiene standards required in retailing milk from ATM. In milk ATM operation, power supply is essential to maintain appropriate low temperature needed to avoid growth of pathogenic bacteria. Because consumers take milk from ATM directly as ready to drink product, failure to maintain appropriate low temperature and practice high standards of hygiene can pose health hazards to consumers.

Though milk ATM is part of the growing Kenyan dairy industry even as milk safety remains a highly debated issue of public concern, information about the ATM as a retailing innovation and their value offer for quality, safer milk is scanty. This study fills these knowledge gaps with a consumer survey and milk quality testing to assess whether milk ATM offers positive sales margin to entrepreneurs and affordable milk to consumers able to meet safety and quality standards. It also assesses the risks that consumers associate with the milk from ATM.

MATERIALS AND METHODS

Study design and data collection

A cross sectional market and consumer survey was conducted in five major towns (Nairobi city, Nakuru, Eldoret, Kakamega and Kisumu) representing a high concentration of urban milk demand in the country. Because of insecurity situation related to the 2017 elections in Kenya at the time of the survey, consumers were not interviewed in Kisumu town while milk samples for quality testing were not collected in Kakamega town. A sample of consumers (n=368), milk ATM entrepreneurs (n=39) and milk samples (n=92) retailed in ATM, plastic containers and as packaged milk were randomly obtained at the milk retail outlets (roadsides, milk bars and supermarkets). Sampling was along a transect line from the central business district (CBD) to the peri-urban zones in each of the towns. Premises with milk ATM were identified, and then the operator approached for an interview that was guided by a check list to capture the operational costs, sales and revenues and to purchase milk for quality testing later in the laboratory.

Interviews with consumers and ATM operators were conducted at the milk business premises when consent was granted following an explanation of the research objectives and use of the information volunteered with assurance of confidentiality. Consumers were approached when coming out of the retail outlets for an interview using a structured questionnaire. Consumers were asked to rate the risks they associate with marketed milk from milk bar ATM, supermarket ATM, packaged milk and milk in plastic container. The rating was for risk of adulteration, unhygienic handling, bacterial load, and chemical preservatives and drugs/antibiotics presence in milk on a Likert scale (of 1=no risk, 2=low risk 3=moderate risk, 4= high risk and 5= very high risk).

In addition to rating marketed milk for risks, consumers ranked milk for preference reasons on a scale of first, second and third importance. The preference reasons ranked were price, organoleptic (smell, taste, appearance), creaminess (fat content), safety from chemical and biological hazards (peroxide, antibiotics, bacterial load, aflatoxin), safety from adulterations (water, flour, blue band), packaging, consistence in availability, hygiene (cleanliness, sanitation standards at sale point), traceability assurance, and brand name.

At the retail outlets, small quantities of milk were purchased for laboratory test of the quality and safety indicators. Approximately 120ml of milk was aseptically collected into sterile air tight containers, then maintained at 4°C using coolants in cool boxes. The milk samples were submitted within six hours to an accredited commercial food and industrial laboratory for quality analysis of Total Viable Counts (TVC), Total Coliform Counts (TCC), milk density (g/ml), solids-not-fat, concentration of aflatoxin M1, and presence of hydrogen peroxide and antibiotic residues. In the laboratory, analysis of TVC and TCC followed the standard protocols of ISO 4833 and ISO 4832 respectively. Analysis of milk density was done with a lactometer while percent solids not fat was computed from Richmond formulae. Presence of hydrogen peroxide was detected with peroxide strips and presence of antibiotics was detected with the Beta Combo S Kit. The concentration of aflatoxin AFM1 in the milk samples was determined from use of competitive enzyme-linked immunosorbent assay (cELISA) kit (Helica Biosystems Inc., Fullerton, CA, USA) guided by the manufacturer’s instructions. The aflatoxin levels in the samples were estimated from the optical densities of the test with an equation created from the optical densities of the kit standards. The use of this method in past studies attained recovery rates of between 70 and 156%, with negative samples not exceeding 4 ppt [12,13].

Data analysis

The operational cost, business turnover and retail margins in milk ATM enterprise were computed from data obtained in interviews with operators about their enterprises. The risk that consumers associate with milk retailed in ATM, plastic containers or packaged milk was determined as perceived risk index, accounting for observed frequencies of the scale rank that a consumer assigned:

Perceived risk index = (1 × frequency of consumers choosing no risk + 2 × frequency of consumers choosing low risk + 3 × frequency of consumers choosing moderate risk + 4 × frequency of consumers choosing high risk + 5 × frequency of consumers choosing very high risk) ÷ sum of consumers (1 × total consumers choosing no risk + 2 × total consumers choosing low risk + 3 × total consumers choosing moderate risk + 4 × total consumers choosing high risk + 5 × total consumers choosing very high risk). The greater the magnitude of computed risk index the greater the risk exposure in the perception of the consumers.

The consumer preference for milk retailed in ATM, plastic containers or packaged milk was determined from computation of preference index, accounting for observed frequencies of the rank for a reason of preference:

Preference index = (3 × frequency of consumers selecting 1st rank + 2 × frequency of consumers selecting 2nd rank + 1 × frequency of consumers selecting 3rd rank) ÷ sum of consumers (3 × Total consumers selecting 1st rank + 2 × Total consumers selecting 2nd rank + 1 × Total consumers selecting 3rd rank). The greater the magnitude of computed preference index the greater the preference that consumers associate with the product.

To determine milk quality and safety differences between retailing options (packaged milk, plastic container and ATM), a general linear model was fitted with dependent variables being the microbiological (TVC and TCC) counts transformed to log10cfu/ml, solids not fat and aflatoxin concentration. Chi square test statistics was applied in detecting proportional differences in samples that were non-compliant with the quality standards and for positive samples for hydrogen peroxide and antibiotics.

RESULTS

Operating costs and retail margins in ATM enterprise

Table 1 is a summary of daily business turnover observed among the sample milk ATM enterprises. The milk ATM in the market vary in capacities between 200 and 1500 litres and are imported (from Italy, Chinaor the Netherlands) at a value ranging from KES 150,000 to 700,000 (US$ 1,500-7,000: exchange rate is 1US$ to KEE 100) or locally assembled. Entrepreneurs of milk ATM buy milk from suppliers at market price between KES 55 and 60 a litre (US$ 0.55 and 0.60) then retail at a margin of KES 5 to 10 a litre (US$ 0.05-0.10).On average, daily milk sale volumes are up to 1500 litres in the cooperatives operated milk ATMs, 600 litres in supermarkets operated milk ATMs and 200 litres in milk bars operated milk ATMs. These translate to gained margin of KES 1,000 to 15,000 a day (US$ 10 to 150) for an entrepreneur.

|

Costs and revenue sources |

KES |

US$ |

|

Machine purchase price |

150,000 -700,000 |

1,500 -7,000 |

|

Milk buying price from suppliers per litre |

55 - 60 |

0.55 -0.60 |

|

Milk selling price per litre at the vending machine outlet |

60 - 70 |

0.60 -0.70 |

|

Retail margin per litre |

5 - 10 |

0.05 -0.10 |

|

Business turnover per day |

|

|

|

· Milk bars |

1,000- 2,000 |

10 -20 |

|

· Supermarkets |

3,000- 6,000 |

30-60 |

|

· Cooperatives |

7,500 - 15,000 |

75 - 150 |

Table 1: Ranges in business turnover of milk ATM (milk vending machine).

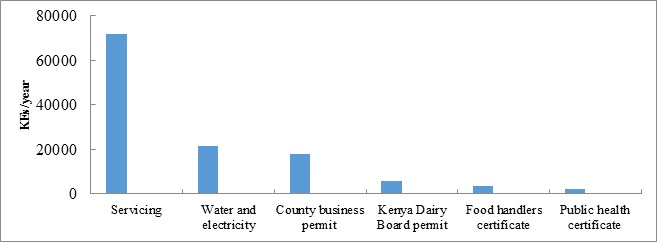

The operational costs obtained from the survey are indicative of what it cost to run milk ATM enterprise (Figure 1). On average, it cost KES 123,200 annually (US$ 1,232) or on a monthly basis, KES 10,266.67 (US$ 102.67) to run milk ATM enterprise. Of this cost, over half (58.4%) is spent on servicing the machine, about a quarter (24.0 %) is spent in licences and permit fees charged by the regulatory authorities (both county and national governments), and about a fifth (17.5%) is spent paying for water and electricity bills. From the information collected, rent of the premise, detergents and wages of the attendants could not be estimated.

Figure 1: Cost categories of operating a milk vending machine (ATM) enterprise in Kenyan town.

Figure 1: Cost categories of operating a milk vending machine (ATM) enterprise in Kenyan town.

Consumer risk perception and preferences for retail milk

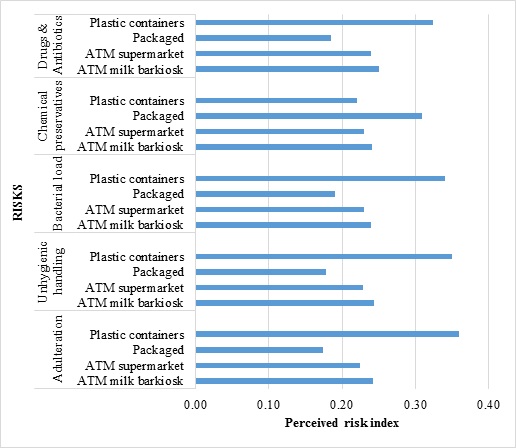

Figure 2 presents the perceived risk index of milk adulteration, unhygienic handling, bacterial contamination, and presence of chemical preservatives and veterinary drug residuals. To consumers, the risks exposures do not differ for milk from ATM in milk bars and in supermarkets. However, milk from the ATM is of relatively greater risk exposure than packaged milk, except for presence of chemical preservatives. The presence of chemical preservatives in milk is of greater risk in packaged milk than in ATM or packaged milk while milk from plastic containers is of greater risks than the milk from ATM.

Figure 2: Perceived risk index of milk adulteration, unhygienic handling, bacterial contamination, and presence of chemical preservatives and drug residuals for retail milk in ATM (milk vending machine), packaged or in plastic containers.

Figure 2: Perceived risk index of milk adulteration, unhygienic handling, bacterial contamination, and presence of chemical preservatives and drug residuals for retail milk in ATM (milk vending machine), packaged or in plastic containers.

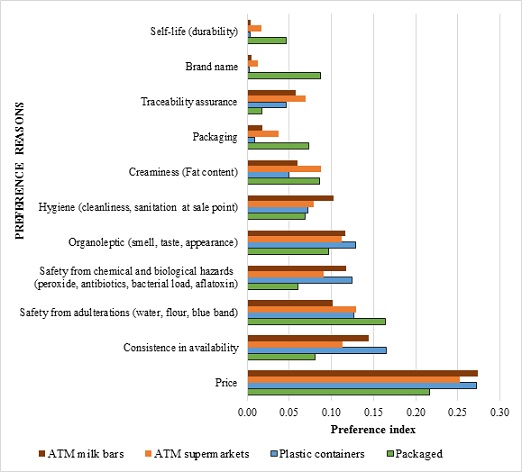

Figure 3 shows the consumer preference index form ilk retailed in ATM, packaged or in plastic containers. Results show that consumers prefer milk from ATM over packaged milk because of several reasons, which are price, consistency in availability, organoleptic attributes, and hygiene in the premises, traceability and safety from chemical and biological hazards but not because of safety from adulteration, shelf-life and branding and packaging. Also, consumers prefer milk from ATM over milk from plastic containers because of several reasons, which are consistency in availability, hygiene in the premises, traceability and creaminess. Figure 4 shows the milk vending machine.

Figure 3: Preference index score of consumer preferring retail milk in ATM (milk vending machine), packaged or plastic containers.

Figure 3: Preference index score of consumer preferring retail milk in ATM (milk vending machine), packaged or plastic containers.

Figure 4: Milk vending machine (ATM).

Figure 4: Milk vending machine (ATM).

Quality and safety of milk in the retail outlets

Table 2 presents the milk quality tests for samples from ATM, plastic containers and packaged milk. Included in the table as well is the prevalence of samples that fail to meet the legal standards prescribed in Kenya and enforced by the Kenya Bureau of Standards (KEBS).The density of traded milk should be between 1.026 and 1.032 g/ml, which all the sample milk met. The KEBS standards prescribes solids not fat of not less than 8.5 %, which packaged milk met but not milk from ATM and from plastic containers. The prevalence of noncompliance in solids not fat in milk from ATM (55.3%) is more than is with packaged milk (43.8%) but is comparable to milk from plastic containers (59.1%).

|

Quality indicator |

Milk retailing |

Sample ( n) |

Mean and SD |

Samples noncompliant (%) |

|

Density (g/ml) |

ATM |

38 |

1.027±0.002a |

0 |

|

|

Packaged |

32 |

1.028±0.001a |

0 |

|

|

Plastic |

22 |

1.027±0.003a |

0 |

|

|

|

|

|

|

|

Solids not fat (%) |

ATM |

38 |

8.45±0.37b |

55.3 |

|

Packaged |

32 |

8.51±0.27a |

43.8 |

|

|

Plastic |

22 |

8.36±0.37b |

59.1 |

|

|

|

|

|

|

|

|

Total Viable Counts (TVC) (log 10 cfu/ml) |

ATM |

38 |

1.60±2.46a |

18.4 |

|

Packaged |

32 |

1.50±1.64a |

0.0 |

|

|

Plastic |

22 |

4.62±2.81b |

68.2 |

|

|

Total Coliform Counts (TCC) (log 10 cfu/ml) |

ATM |

38 |

1.19±2.15a |

23.7 |

|

Packaged |

32 |

1.01±1.37a |

28.1 |

|

|

Plastic |

22 |

3.84±2.47b |

77.3 |

|

|

Aflatoxin AFM1 (ppt)* |

ATM |

14 |

88.79±84.91b |

0 |

|

Packaged |

9 |

101.99±60.41b |

0 |

|

|

Plastic |

7 |

51.59±72.86a |

0 |

|

|

Hydrogen peroxide presence (%) |

ATM |

38 |

|

7.9 |

|

Packaged |

32 |

|

6.3 |

|

|

Plastic |

22 |

|

4.5 |

|

|

Antibiotic presence (%) |

ATM |

38 |

|

7.6 |

|

Packaged |

32 |

|

6.5 |

|

|

Plastic |

22 |

|

4.3 |

Table 2: Quality of milk samples from ATM, packaged and plastic containers. Means for a quality indicator with different letter superscript differ at p<0.05. *Aflatoxin results are reported on a subset sample that could be analysed. *Codex maximum tolerable AFM1 concentration of 500ppt standards apply.

The milk microbial load prescribed in KEBS standards regarding TVC in raw milk is counts less than log10 6cfu/ml and in pasteurized milk is counts less than log10 4.47 cfu/ml. The standards for TCC in raw milk is counts less than log10 4.69 cfu/ml and in pasteurized milk is count less than log10 1.00 cfu/ml. By these standards, milk from ATM and packaged milk retailed as pasteurized milk are compliant with the KEBS standards in the average total viable counts but not in the total coliform counts (Table 2). Milk from plastic containers retailed as raw milk are compliant with the KEBS standards in both average total viable counts and coliform counts. For noncompliance among the milk samples, the milk from ATM show lower prevalence in both total viable counts and coliform counts (<24%) than milk from plastic containers (68%), but are comparable to packaged milk (29% in coliform counts).

The maximum safe limits for aflatoxinAFM1 concentration in milk applicable in Kenya are 500 ppt recommended by Codex standards, which the country subscribes to in the absence of own prescribed standards. By Codex standards, milk samples from ATM, plastic containers and packaged milk are all within the safe limits, with milk from plastic containers being markedly lower in AFM1 concentration. In the KEBS standards, presence of hydrogen peroxide and antibiotics is prohibited in traded milk. In the milk samples, prevalence of both hydrogen peroxide and antibiotics is relatively more in milk from ATM (8%) compared to milk from plastic containers (4.5%) but comparable to contamination in packaged milk (6%).

DISCUSSION

Operational costs and returns in running ATM enterprise

More than half of the operational cost in ATM enterprise is for servicing, which reflects efforts by entrepreneurs to implement scheduled servicing as instructed by the manufacturers. But the high cost of servicing present concern in the running of ATM enterprise because entrepreneurs are likely to skip some servicing schedules in order to reduce operational costs. This would be a failure in complying with the regulations requiring that ATM retails only pasteurized milk.

In this study the operator declared that one sample out of thirty nine samples was raw milk, suggesting that not all milk from ATM are pasteurized. Retailing unpasteurized milk in the ATM pose the risk of compromising the quality and safety of traded milk. This should inform the authorities controlling food safety to direct effective quality inspections towards checking trade malpractices in milk ATM retailing [7,8,14].

Though the ATM are imported, emerging local assembling is evident, which would grow with increased uptake of the ATM for milk retailing. It would be beneficial to the efforts of formalizing milk market in Kenya to support local innovation in fabricating and assembling ATM because it would make the machines affordable and create jobs in the dairy value chain.

Consumers are attracted to milk from ATM because milk is retailed at a price half lower (KES 60 to 70; US$ 0.60 to 0.70) than the retail price of 1 litre of pasteurised, packaged milk (KES 120; US$ 1.2). This means that consumers save KES 50 to 60 (US$ 0.50 to 0.60) per litre of milk. The saving is an economic incentive in markets where consumers prioritize price and consistent availability over milk safety as they may be unwilling or unable to pay a premium price for packaged milk [15]. The retail margins per litre of milk of up to KES 10 (USD 0.1) are a business attraction to SMEs, depending on the volume of milk traded. They can cash on this market opportunity in responding to the growing domestic consumption demand for processed milk and dairy products evident in the economic surveys.

The milk sale volumes between 2013 and 2018 [16] increased by 21.3 % in processor milk intake, by 11.7 % in processed milk and cream, by 46.1 % in cheese and by 1.5 % in butter and ghee. These growth trends in manufacturing high value milk and dairy products present an increasing demand by processors for supply of high quality and safe milk. Some of the high value milk and dairy products are the pasteurised ready to drink milk retailed in ATM, targeting urban consumers. But running ATM enterprise require secured access to stable supply of clean water and electricity to observe the hygiene practices and to avoid compromising quality and safety of milk to consumers. If the growing consumption demand trends continue, pasteurised milk from ATM would be a growing segment of the milk retail market. The government can support growth of ATM in milk retailing with evidence base to inform targeted response to this likely growth scenario by understanding better the likely growth trends, consumer demands and policy responses that may support or discourage further growth of milk ATM in the country.

Consumer perception of risk exposure and purchase preferences for milk from ATM

Consumer perception of risk reflects their awareness of the potential risks exposure in milk consumption and they associate some milk retailing with more risks than the others. For the risks assessed, consumers hold the perception that milk from ATM is as safe as packaged milk while milk from ATM is safer than milk from plastic containers. This observation would suggest consumer acceptance of milk retailing in ATM. Viewed from market-led perspectives, milk ATM retailing represent a new segment of formal milk share and therefore supportive to strategic objective of formalisation of milk market in Kenya as aspired for in the national dairy master plan [1,2]. It is a viable business opportunity that SMEs working closely with the government can build upon with good food safety assurance practices in contributing to the strategic development objective of the dairy industry.

It is clear from results of this study that consumers express low confidence in milk retailed from plastic containers as compared to milk retailed from ATM or packaged milk. Their perception of risk of milk from plastic containers is corroborated with the observed milk quality in this study. Then on compliance in microbial quality was more prevalent in plastic containers than in ATM or in packaged milk. However, use of plastic containers in milk retailing remains widespread in the market outlets [3, 4]. This continues despite the introduction of small sized aluminium containers and improved plastic containers (mazzican containers) as alternatives to replace the plastic containers in efforts to improve milk hygiene and quality standards.

However, uptake of mazzican containers in milk retailing remains very low: only 4% (5/130) observed in milk retailing in this study. Predominant use of plastic containers in milk transport and retailing can be attributed to its low cost, though discouraged for milk handling because of difficulties in cleaning. It is possible to eliminate the prevalent use of plastic containers in milk handling if the government can extend the ban on plastic carrier bags successfully enforced in the country since 2017 to plastic containers (https://www.dw.com/en/visiting-kenya-a-year-into-its-plastic-bag-ban/a-45254144 ).

That consumers perceived presence of chemical preservatives (hydrogen peroxide) a greater risk in packaged milk than in milk from ATM or from plastic containers demonstrate consumer low confidence in both formal and informal milk retailing for quality and safety assurance. It points to consumers perceiving that chemicals are used in milk processing. Milk processors should consider this a consumer concern in milk quality and safety assurance. It is an indication that processed milk has failed to guarantee consumers safety as they express higher preference for milk from ATM over packaged milk on several attributes for which packaged milk would justify charging premium price. This study has established that milk from ATM is more attractive than the packaged milk for several reasons: price, consistent availability, traceability and safety from chemical and biological hazards. The observation corroborates those of Paraffin et al., [15] that consumers prioritise price and convenience over safety in their milk purchasing behaviours.

Quality of milk from ATM

It is worth noting that while the average milk density (1.027 g/ml) meets the national standards (KEBS), the density would fail in case of export trade to other East African countries where the common market applies milk density standards of between 1.028 and 1.036 g/ml. Kenya as a member state of the Community would have its fluid milk products not enter into the regional market on suspicion of milk adulteration. Common adulteration is with water to increase volume of milk, but this lowers milk nutritional value, compromises milk processing qualities and can introduce contaminants in milk. Adulteration of milk may be intentional through addition of water or unintentional through mastitis infection, which lowers the density [17]. Mastitis can be managed with improved hygienic practices. Intentional addition of water can be deterred with a combination of education and penalties whenever is detected. In the present study, prevalence in noncompliance with solids not fat is much higher (49-59%) than the levels (<33%) previously observed in both rural and urban milk samples [5,18]. However, this study used a lactometer to determine milk density. This tool has a limitation if adulteration is by addition of skimmed milk, flour, sugar or removal of fat, which are some of the malpractices in informal milk trade. Complementing a lactometer with a cryoscope to measure the freezing point would address this weakness, where and whenever possible.

In the present study, milk samples noncompliant for the total bacterial counts are prevalent in milk from ATM (18.4%) but all samples of packaged milk were in compliant with the standards. The observations suggest challenges of keeping high standards of hygienic milk handling practices in the milk ATM operations. This could be traced to poor access to quality water, interruptions in the supply of power and water, poor sanitation during milking, or wet bedding in cow housing, especially zero-grazing units where cows are milked and housed overnight [11]. The noncompliance in microbial quality observed in milk from plastic containers (68% to 77%) in the present study compares to previously observed noncompliance (70% to 88%) in traded milk in Nairobi city [18]. Presence of high numbers of bacterial counts increase the risk for post-harvest losses related to milk going off-flavour, reduced quality and/or reduced shelf-life [19,20]. This further emphasises why secured access to stable supply of clean water and electricity is necessary in running ATM enterprise for enabling hygiene practices and avoiding compromising the quality and safety of milk.

In the present study, prevalence of residual antibiotics in milk from ATM (7.6%) is much lower than observed in recent studies in Kenyan towns: 18.4% in milk from vendors in coastal Kenya [6] and 24.0% in milk from ATM in Eldoret town [7], though earlier studies reported very low prevalence (2.2%) around Nairobi city [18,21]. This difference could be a reflection of the level of adherence to antibiotic withdrawal periods after treatment of cows. Farmers belonging to cooperative societies and delivering milk to processors can better observe antibiotic withdrawal periods following treatment to avoid milk rejection by the milk cooperative and processors when antibiotic presence is detected. Farmers need be further educated that observing ethics and the antibiotic treatment withdrawal period as instructed by the manufacturers minimizes the risks of progressive development of antimicrobial resistance in humans and animals and is a good practice to implement on their farms.

Kenya as other countries that are yet to set their own maximum safe limits for AFM1 in milk rely on the Codex standards. The standards provide the global benchmark on food and feed safety to protect consumer health and facilitate trade. They serve as advisory and not mandatory and so are less stringent (500 ppt) than the European Union (EU) standards (50 ppt) for maximum safe limits of AFM1 concentration allowable in milk. In this study, all the milk samples are safe for human consumption per the Codex maximum safe limits. Benchmarked to the EU standards, the unsafe levels of AFM1 in milk from ATM (50 %) is more prevalent than in milk from plastic containers (29%) but is less prevalent than in packaged milk (78 %).Though obtained from smaller milk samples (14 ATM, 9 packaged and 11 plastic containers) in a cross sectional survey, the AFM1 concentration compares well with those obtained in a larger milk sample (291) from a one-year longitudinal survey study by Lindahl et al. [12]. These authors detected 74.2% raw milk and 72.2% pasteurized milk samples with AFM1 concentration above the EU set 50 ppt maximum safe limit. For applying AFM1 standards in decision making, some workers advocate for review of the standards to align with the local socio-economic conditions including food security and consumption patterns [4,12,22,23]. Aflatoxin contamination in milk is traced to farmers feeding aflatoxin contaminated feeds in the face of persistent feed scarcity. This concurs with several previous studies [13,22,24,25] that detected in feeds up to 56 %prevalence of aflatoxin levels exceeding 50ppt safe maximum limit. The authors attributed their observation to poor handling and storage of on-farm feeds and pressure of persistent feed scarcity on smallholder dairy farms.

CONCLUSION

The milk ATM retailing is a growing milk retail innovation that can offer competitive price and safety advantages to consumers and business opportunities to SMEs. Though consumers express acceptance to milk retailed in ATM on general perception that the milk is safer than raw milk and is as safe as packaged milk, milk from ATM is not free of hazards and does not guarantee them safety and quality. Therefore education on value of milk quality should be inclusive of all actors along the dairy value chain. Education of farmers on milk hygiene is a priority intervention. ATM milk retailing being a short value chain, traceability of milk quality to the farms presents no logistical challenges to strengthen. Supporting growth of milk ATM as part of formal milk trade needs government intervention in surveillance, quality control and setting standards for local milk dispenser models.

AUTHOR’S CONTRIBUTION

Conceptualization, B.O.B. and J.v.L.; Methodology, B.O.B., J.v. L. and C.W.K.; Software, B.O.B.; Validation, B.O.B., J.v. L. and C.W.K.; Formal Analysis, B.O.B.; Writing-Original Draft Preparation, B.O.B.; Writing- Review & Editing, B.O.B., J.v. L. and C.W.K.; Visualization, B.O.B.; Supervision, B.O.B.; Project Administration, C.W.K.

FUNDING

The publication charges for this article have been funded by 3R Kenya project

ACKNOWLEDGEMENTS

This research was implemented under the 3R Kenya project, funded by the Embassy of the Kingdom of the Netherlands in Nairobi, Kenya, within the framework of the Agriculture and Food & Nutrition Security program.

CONFLICTS OF INTEREST

The authors declare no conflict of interest.

REFERENCES

- http://vetvac.org/galvmed/law/docs/194_dairy_master_plan_strategies_and_action_plans[1]_21-07-2010[1].pdf

- http://kdb.co.ke/press/publications/reports/21-kdb-2014-annual-report/file.

- Bebe BO, Rademaker CJ, van der Lee J, Kilelu CW, Tonui C (2017) Sustainable growth of the Kenyan dairy sector: a quick scan of robustness, reliability and resilience.

- Blackmore E, Alonso S, Grace D (2015) Legitimising informal markets: A case study of the dairy sector in Kenya. In: Shaping sustainable markets, The International Institute for Environmental Development (IIED).

- Ndungu TW, Muliro PS, Omwamba M, Oosterwijk G, Jansen A (2016) Quality control of raw milk in the smallholder collection and bulking enterprises in Nakuru and Nyandarua Counties, Kenya. African Journal of Food Science 10: 70-78.

- Ondieki GK, Ombui JN, ObonyoM, Gura Z, Githuku J, et al. (2017) Antimicrobial residues and compositional quality of informally marketed raw cow milk, Lamu West Sub-County, Kenya. Pan Afr Med J 28: 5.

- Kosgey A, Shitandi A, Marion JW (2018) Antibiotic residues in milk from three popular Kenyan milk vending machines. Am J Trop Med Hyg 98: 1520-1522.

- Orwa JD, Matofari JW, MuliroPS, Lamuka P (2017) Assessment of sulphonamides and tetracyclines antibiotic residue contaminants in rural and peri-urban dairy value chains in Kenya. International Journal of Food Contamination 4: 5.

- Alarm on milk with high levels of bacteria. Sunday Nationon 18th December 2019.

- Mutegi CK, Cotty PJ, Bandyopadhyay R (2018) Prevalence and mitigation of aflatoxins in Kenya (1960-to date). World Mycotoxin Journal 11: 341-357.

- Pereira A, Villanueva-Rey P, Xavier V, Moreira MT, Feijóo G (2018) Fresh milk supply through vending machines: consumption patterns and associated environmental impacts. Sustainable production and consumption 15: 119- 130.

- Lindahl JF, Kagera IN, Grace D (2018) Aflatoxin M1 levels in different marketed milk products in Nairobi, Kenya. Mycotoxin Research 34: 289-295.

- Kirino Y, Makita K, Grace D, Lindahl JF (2016) Survey of informal milk retailers in Nairobi, Kenya and prevalence of aflatoxin M1 in marketed milk. African Jr of food, Agriculture, Nutrition and Development 16: 11022-11038.

- Mailu S, Will M, Mwanza R, Nkanata K, Mbugua D (2014) Milk supply contracts and default incidence in Kenya. Pg no: 57381.

- Paraffin AS, Zindove TJ, Chimonyo M (2017) Household consumption preferences of dairy products and their perceptions of milk safety. Journal of Food Safety 38: 12428.

- Economic Survey 2018, Kenya National Bureau of Statistics, Nairobi. Pg no: 124.

- Sharma N, Singh NK, Bhadwal MS (2011) Relationship of somatic cell count counts and mastitis: An overview. Asian-Australian Journal of Animal Sciences 24: 429-438.

- Orregârd M (2013) Quality analysis of raw milk along the value chain of the informal milk market in Kiambu County, Kenya. Swedish University of Agricultural Sciences 2013: 4.

- Barbano DM, Ma Y, Santos MV (2006) Influence of Raw Milk Quality on Fluid Milk Shelf Life. J Dairy Sci 89: 15-19.

- Giacometti F, Serraino A, Finazzi G, Daminelli P, Losio MN, Tamba M, Garigliani A, Mattioli R, Riu R, Zanoni RG (2012) Field handling conditions of raw milk sold in vending machines: experimental evaluation of the behaviour of Listeria monocytogenes, Escherichia coli O157:H7, Salmonella Typhimurium and Campylobacter jejuni. Italian Journal of Animal Science 9: e24.

- Omore A, Lore T, Staal S, Kutwa J, Ouma R, et al. (2005) Addressing the public health and quality concerns towards marketed milk in Kenya. SDP Research and Development Report No. 3. Nairobi (Kenya): Smallholder Dairy (R&D) Project.

- Senerwa DM, Sirma AJ, Mtimet N, Kang’ethe EK, Grace D, et al. (2016) Prevalence of aflatoxin in feeds and cow milk from five counties in Kenya. Afr J Food Agric Nutr Dev 16: 11004-11021.

- Sirmaa AJ, Lindahl JF, Makita K, Senerwa D, Mtimet N, et al. (2018) The impacts of aflatoxin standards on health and nutrition in sub-Saharan Africa: The case of Kenya. Global Food Security 18: 57-61.

- Makau CM, Matofari JW, Muliro PS, Bebe BO (2016) Aflatoxin B1 and Deoxynivalenol contamination of dairy feeds and presence of Aflatoxin M1 contamination in milk from smallholder dairy systems in Nakuru, Kenya. International Journal of Food Contamination 3: 6.

- Kang’ethe E, Grace D, Roesel K, Mutua F (2020) Food safety landscape analysis: The dairy value chain in Kenya. Nairobi, Kenya: ILRI.

Citation: Bebe BO, van der Lee J, Kilelu C (2020) Milk Vending Machine Retail Innovation in Kenyan Urban Markets: Operational Costs, Consumer Perceptions and Milk Quality. J Dairy Res Tech 3: 019.

Copyright: © 2020 Bockline Omedo Bebe, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.