Nutrient Composition, Physical and Sensory Properties of Cookies Produced from Millet, African Walnut and Unripe Plantain Composite Flours

*Corresponding Author(s):

Ani ECDepartment Of Food Science And Technology, Enugu State University Of Science And Technology, Enugu, Nigeria

Email:emilyani4christ@gmail.com

Abstract

The proximate, mineral and sensory properties of millet, African walnut and unripe plantain composite flour cookies were investigated. The millet, African walnut and unripe plantain flours were blended in the ratios of 90: 5: 5, 80: 10: 10, 70: 15: 15, 60: 20: 20, 50: 25: 25 with the cookies produced from 100% wheat flour as control. The cookies produced were evaluated for proximate, mineral and sensory properties using standard methods. The moisture, protein, fat, ash and crude fibre contents of the cookie samples increased significantly (p≤0.05) from 7.66±0.11 - 10.34±0.17%, 10.66 - 15.11±0.4%, 2.28±0.01 - 2.50±0.03%, 3.25 ± 0.16 - 3.71± 1.36% and 1.31± 0.01 - 2.37± 0.04% with increased substitution of African walnut and unripe plantain flours, while the carbohydrate and energy contents decreased from 74.84± 0.06 - 65.97 ± 0.08% and 362.52± 0.16 - 346.82 ± 3.22 KJ/100g, respectively. The mineral content of the samples showed that the calcium, phosphorus, iron and zinc contents increased with increase in substitution of African walnut and unripe plantain flours from 48.57± 7.03 - 63.76± 0.03mg/100g, 157.87 ± 0.04 - 170.71± 0.66mg/100g, 1.25±0.04 - 1.85±0.01mg/100g and 1.49±0.06 - 1.83±0.04mg/100g, respectively, while the potassium and magnesium contents decreased. The control sample (100% wheat cookies) had the highest potassium (120.97±0.44mg/100g) and magnesium (106.89±0.47mg/100g) contents, respectively. The force - deformation characteristics of the samples decreased significantly (p≤0.05) with increased substitution of African walnut and unripe plantain flours. The control (100% wheat cookies) had better force-deformation characteristics compared to composite flour cookies. The sensory scores showed that the texture, crispiness, taste, aroma and overall acceptability of the control sample were the most acceptable to the panelists compared to the samples substituted with African walnut and unripe plantain flours at different graded levels. Although the control sample had better consumers’ sensory attributes, it was the lowest in nutrient contents compared to the composite flour cookies with exception of carbohydrate, potassium and magnesium. The study, therefore, showed that cookies of acceptable nutrient contents and sensory properties could be produced from millet, African walnut and unripe plantain composite flours.

Keywords

Cookies production, composite flour, proximate, mineral, force-deformation characteristics, sensory attributes.

Introduction

Cookies are a form of confectionery products usually dried to low moisture content [1]. When compared to biscuits, they tend to be larger with a softer, acceptable texture and usually contain flour, sugar and some type of oil or fat. They may be mass- produced in factories or made in small bakeries or homes. They are consumed all over the world as snacks and on a large scale in the developing countries where protein-energy malnutrition is prevalent especially among children and adolescents [2]. The snack industry is growing globally with the rapid introduction of new products formulated with the intent of meeting specific health or organoleptic needs of consumers.

Cookies which are cereal- based products are poor sources of protein because they are produced from wheat flour which has low protein content. The complementary role of legume protein and the increased cost of animal protein for human food have made legumes important as alternative sources of dietary protein [3,4]. The legumes that are commonly consumed in Nigeria and other sub - Sahara African countries include pigeon pea, cowpea, African bread fruit, Bambara groundnut, soybean and African yam bean etc. The use of indigenous flour substitutes for wheat to produce composite flour for the preparation of baked products is therefore necessary. Composite flour can be defined as a mixture of several flours obtained from roots and tubers, cereals and legumes etc, with or without the addition of wheat flour. It can also be defined as a mixture of different flours from cereals, legumes or root crops that is created to satisfy specific functional characteristics and nutrient composition [5]. These grains can be processed traditionally to improve their nutritional quality. However, due to their low protein content, they are susceptible to modification. Modification of protein is usually realized by physical, chemical and biological methods such as fermentation or an enzymatic treatment, which changes its structure and consequently its physicochemical and functional properties [6].

The protein of the millet is quite similar to that of wheat. The only glaring exception is that millet is a non- gluten grain. Despite their excellent nutritional quality, millet grains have received less attention compared to some major cereals like rice, wheat and corn. The production of gluten-free food products with low glycemic index makes millet to be important in recent times. Millets are high in carbohydrate and energy contents. It has been reported that millet proteins are good sources of essential amino acids with the exception of lysine and threonine but are relatively high in methionine [7]. African walnut (Tetracarpidium conophorum) is a good protein source but it is underutilized. It is often found growing wild as a climber in the forest regions of Africa and India [8]. It has a long history as food plant and is grown by peasant farmers. It is widely distributed in southern part of Nigeria [9]. Plantain is an important staple food as well as the raw material for industries producing value added products in many parts of Nigeria. Due to its high demand in the country, the economic status of this crop as a foreign exchange earner has been hampered in recent times. It plays a strategic role in rapid food production because it is a perennial crop with short gestation period [10]. It is cheap and good sources of energy, vitamin C, vitamin A and mineral elements like magnesium, folate, iron and potassium [11]. The utilization of these food materials as composites in the preparation of cookies would help to improve their nutrient contents and sensory properties. Therefore, the study was designed to produce and evaluate the nutrient composition, physical and sensory properties of cookies from composite flours of millet, African walnut and unripe plantain.

Materials and Methods

The pearl millet, African walnut and unripe plantain used for the study were purchased from Ogbete Main Market, Enugu, Enugu State, Nigeria, while the other baking ingredients such as wheat flour, butter, baking powder, sugar, salt, and egg were purchased from the same market.

Preparation of malted millet flour

The malted millet flour was prepared according to the method of Jideani [12]. One kilogramme (1kg) of the pearl millet grains were sorted to remove dirt and other extraneous materials. The sorted grains were winnowed, cleaned and soaked in 3 litres of potable water in a plastic bowl at room temperature (30±2°C) for 18 h with a change of water at every 6 h to prevent fermentation. The soaked grains were drained, rinsed and immersed in 2% sodium hypochlorite solution for 10 min to sterilize the grains. Thereafter, the grains were rinsed with excess water for five consecutive times and cast on a moistened jute bag, covered with a polyethylene bag and left for 24 h to fasten sprouting. After that, the grains were quietly spread on a jute bag and allowed to germinate in the germinating chamber at room temperature (30±2°C) and relative humidity of 95% for 96 h. During this period, the grains were sprinkled with water at every 14 h to facilitate germination. Non- germinated grains were handpicked and discarded. The germinated grains were collected, spread on the trays and dried in a hot air oven (Model Gollenkamp 300 Plus, England) at 60°C for 20 h with occasional stirring of the grains at intervals of 30 min to ensure uniform drying. The dried millet malts were cleaned and rubbed in- between palms to remove the roots and shoots. The millet malts were milled in an attrition mill (Model Globe P44, China) and sieved through a 400 micron mesh sieve. The flour produced was packaged in an airtight plastic container, labelled and stored in a freezer until needed for further use.

Preparation of African walnut flour

The African walnut flour was prepared according to the method of Barber and Obinna-Echem [13]. One kilogramme (1kg) of freshly harvested African walnuts were thoroughly cleaned to remove dirt and other contaminants. The cleaned nuts were manually de-shelled by cracking them with a kitchen knife to obtain the seeds. The de-shelled seeds were cut into smaller slices with a knife. The African walnut slices were rinsed, put in a stainless pot and boiled with 3 litres of potable water at 1000C for 40 min on a hot plate. The boiled slices were drained, rinsed and spread on the trays and dried in a hot air oven (Model Gallenkamp 300 Plus, England) at 600C for 24 h with occasional stirring of the slices at intervals of 30 min to ensure uniform drying. The dried slices were milled in an attrition mill (Model Globe P44, China) and sieved through a 400 micron mesh sieve. The flour produced was packaged in an airtight plastic container, labelled and kept in a freezer until needed for further use.

Preparation of unripe plantain flour

The unripe plantain flour was prepared according to the method of Chinma and Gernah [2], with slight modifications. One kilogramme (1kg) of mature unripe plantain fruits were thoroughly cleaned and peeled manually with a kitchen knife. The peeled plantain fruits were cut into smaller sizes with a knife. The slices were rinsed, placed into a stainless pot and blanched with 3 litres of potable water at 85°C for 20 min on a hot plate. The blanched slices were drained, rinsed and spread on the trays and dried in a hot air oven (Model Gallenkamp 300 Plus England) at 60°C for 18 h with occasional stirring of the slices at intervals of 30 min to ensure uniform drying. The dried slices were milled in an attrition mill (Model Globe P44, China) and sieved through a 400 mesh sieve. The flour produced was packaged in an airtight plastic container, labelled and stored in a freezer until needed for further use.

Formulation of flour blends

Millet Flour (MF), African Walnut Flour (AWF) and Unripe Plantain Flour (UPF) were thoroughly mixed together in the ratios of 90: 5: 5, 80: 10: 10, 70: 15: 15, 60: 20: 20, and 50: 25: 25 in a Kenwood mixer (Model NX 908 G, Kenwood, Britain, UK) to produce composite flours. The composite flours produced were packaged separately in plastic containers, labelled and kept in a freezer until needed for cookie production.

Preparation of cookies

The cookies were prepared according to the method of Okpala et al. [14]. The recipe used for the preparation of cookies contained 100% flour, 40% sugar, 80% fat, 2% baking powder, 2% salt, 5% beaten eggs and 5% vanilla flavour. During preparation, sugar, flour, baking powder and salt were hand mixed in a plastic bowl. Then, fat was added and the mixture was mixed further by hand until a bread crumb- like mixture was obtained. The mixture was transferred into a food processor (Home luck). The beaten egg and flavour were added and the mixture was mixed thoroughly at medium speed for 5 min to obtain the dough. The dough was manually rolled out on a flat and smooth floured board into sheets of uniform thickness of 4cm and cut with a circular cookie cutter. The cut doughs were transferred into baking trays lined with greased proofed paper and baked at 180°C for 20 min in a domestic oven (Camara, Italy). Thereafter, the cookies were cooled at room temperature (30± 2°C), packaged separately in air tight plastic containers, labelled and kept in a freezer until needed for analyses.

Proximate analysis

The moisture, crude protein, fat, ash and crude fibre contents of the cookie samples were determined in triplicate according to the standard analytical methods of AOAC [15]. Moisture was determined by drying 2g of the milled cookie samples in an air oven at 105°C for 3 h. Protein content (%N × 6.25) was determined by the Kjeldahl method. Fat was determined by Soxhlet extraction method with petroleum ether at 50°C. The ash content was determined gravimetrically after incineration in a muffle furnace at 500°C for 24 h. Crude fibre was determined by difference after the incineration of the ash-less filter paper containing the insoluble materials from the hydrolysis and washing of moisture- free defatted sample (1g). Carbohydrate content was calculated by difference on dry sample weight by subtracting the summation of the percentage moisture, protein, fat, ash and crude fibre contents from 100%. The energy content of each sample was calculated by multiplying the percentage of crude protein, fat and carbohydrate of the samples in each case using the Atwater factors of 4, 9 and 4, respectively.

Mineral analysis

The minerals were extracted by dry-ashing of the samples at 500°C to constant weight followed by the dissolution of the ash in volumetric flask by the addition of 50mL of de-ionised water and a few drops of concentrated hydrochloric acid. The calcium, phosphorus, iron and zinc contents of the samples were determined by the use of atomic absorption spectrophotometer (Model 320N) according to the standard methods of AOAC [15]. The potassium content was estimated by the flame photometer (Model FP 640), while the magnesium content was determined by the method of Onwuka [16].

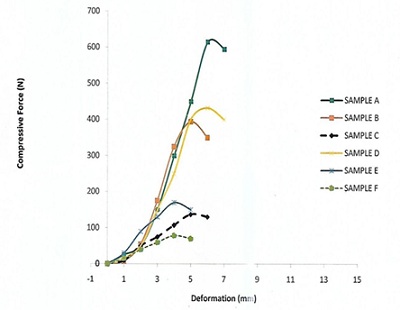

Force-deformation characteristics

The compression strength test was conducted on the cookie samples using computer aided INSTRON Universal Testing Machine (IUTM) as described by Chauhan et al. [17]. The cookie samples were loaded and compressed at the cross-head load of 5KN at high speed for 5 min. As the compression began and progressed, a load-deformation curve was plotted automatically in relation to the response of each sample under compression. The IUTM compressed the sample until the first crack which showed that the compressive or breaking strength of the cookies was noticed. Thereafter, other parameters such as energy at maximum load and slope of the curve were recorded.

Sensory evaluation

The wheat and composite flour cookies produced were cooled for 2 h at room temperature (30±2°C) after baking and were assessed sensorily by twenty (20) semi-trained consumer panelists consisting of staff and students of the Department of Food Science and Technology, Enugu State University of Science and Technology (ESUT), Enugu. During the sensory test, the cookies were individually coded and served to the panelists in white ceramic plates of uniform sizes. The panelists were asked to taste, evaluate and rate the samples using a nine (9) point Hedonic scale for the attributes of colour, taste, texture, aroma, crispness and overall acceptability. A cup of drinking water was also provided to each panelist to rinse his or her mouth after tasting each sample to avoid residual effect. The panelists were instructed to evaluate and score the cookie samples based on their degree of preference and acceptance of each product.

Statistical analysis

The data generated were subjected to one-way Analysis of Variance (ANOVA) using Statistical Package for Social Sciences (SPSS, version 20) software. Significant means were separated using Duncan’s New Multiple Range Test (DNMRT) at p<0.05 and the results were expressed as mean ± standard deviation of triplicate determinations.

Results And Discussion

Proximate composition of millet-African walnut-unripe plantain composite cookie samples

The proximate composition of the cookie samples are presented in table 1. The moisture content of the cookie samples varied significantly (p<0.05) from each other. The moisture content ranged from 7.66 to 10.34% with the control sample having the least moisture content (7.66%), while the sample substituted with 25% African walnut and 25% unripe plantain flours had the highest moisture content (10.34%). The result is in agreement with the report of Echendu et al. [18], for biscuits made with maize/pigeon pea flour blends. High moisture is not desirable in foods because it affects the shelf life of food products. Cookie products with moisture content less than 13% are more stable from moisture dependent deterioration [19]. The protein content of the samples showed that the protein content of the cookies increased significantly (p<0.05) with increase in substitution with African walnut flour and this is in agreement with the report that African walnut has high protein content [20,21]. Hassan and Umar [22], reported that any plant food that supplies or provides more than12% of its energy from protein is considered a good source of protein. Protein is important in the building and maintenance of cells in the body. The fat content of the samples increased significantly (p<0.05) with increase in substitution with African walnut flour and this is in consonance with the fact that African walnut is a rich source of fat [8,20,21,23]. The oil extracted from African walnut has been reported to be an excellent source of Omega-3 essential fatty acids; a special type of protective fat the body cannot manufacture [24]. Cookies are regarded as a rich source of fat; hence they are energy giving food [25]. The ash content of the cookies increased from 3.25% (100%wheat cookies) to 3.71% (Composite cookies substituted with 25% African walnut and 25%unripe plantain flours). The ash content obtained in this study was higher than the ash content reported by Eneche [26], for biscuits produced from millet/pigeon pea flour blends. The ash content of a food material could be used as index of the mineral constituents of the food [27]. The crude fibre content of the cookie samples ranged from 1.31 % in the control sample to 2.37% for the sample containing millet flour substituted with 25% African walnut and 25% unripe plantain flours, respectively. This showed that African walnut and unripe plantain flours are good sources of fibre and hence, they can be used in preparation of functional food products. The consumption of high fibre food products has been reported to reduce the onset of hermorrhoids, diabetes, high blood pressure and obesity in humans [28,29]. The fibre content of the cookies is within the FAO/WHO [30], level of not more than 5%. The carbohydrate content of the cookie samples ranged from 65.97 to 74.84%. The carbohydrate contents of all the composite cookie samples were significantly (p<0.05) lower than the control. The decrease in carbohydrate content of the samples could be attributed to the fact that millet is mostly a carbohydrate rich food, hence the reduction in millet content resulted in decrease in carbohydrate content of the samples. Ihediohanma et al. [31], also reported a decrease in carbohydrate content of cakes with increasing substitution of African bread fruit flour. The energy content of the cookie samples ranged from 346.82 to 362.52KJ/100g. The control sample without any substitution had the highest energy value (362.52KJ/100g), while the cookies substituted with 25% African walnut and 25% unripe plantain flours had the least energy content (346.82KJ/100g). The observed differences in the energy levels of the cookies could be attributed to variation in protein, fat and carbohydrate contents of the samples. The result obtained in this study are similar to the findings of Nzeagwu and Nwaejike [32], who reported a decrease in the energy content of supplementary foods with increasing substitution of groundnut and crayfish flours. Okaka [33], reported that cookies are energy giving foods which are consumed by both young and old, especially in between meals. The consumption of 15-20 pieces of cookies can provide adequate energy per day based on recommended dietary allowances of 7.6Megajoules for children and 10.8Megajoules for adults. The substitution of millet-based cookies with African walnut and unripe plantain flours greatly improved the protein, fat, ash and crude fibre contents of the samples.

|

Sample ID |

% Substitution WF:MMF:AWF:NPF |

Moisture |

Protein |

Fat |

Ash |

Fibre |

Carbohydrate |

Energy (KJ/100g |

|

A |

100 : 0 : 0 : 0 |

7.66f±0.11 |

10.66f±0.11 |

2.28f±0.01 |

3.25e±0.16 |

1.31f±0.01 |

74.84a±0.06 |

362.52 a±0.16 |

|

B |

0 : 90 : 5 : 5 |

9.25 e±0.04 |

11.62e ±0.08 |

2.30d±0.0 |

3.40d±0.13 |

1.44 e±0.03 |

71.99b±0.01 |

355.14 b±0.41 |

|

C |

0 : 80 : 10 : 10 |

9.62 d±0.08 |

12.12d ±0.62 |

2.32d±0.06 |

3.43d ±0.07 |

1.49 d±0.01 |

71.02 c±0.62 |

353.44c±0.19 |

|

D |

0 : 70 : 15 : 15 |

9.67 b±0.13 |

13.50c ±0.37 |

2.38 c±0.08 |

3.51c ±0.11 |

1.68 c±0.06 |

69.26 d±0.37 |

352.46 d±0.76 |

|

E |

0 : 60 : 20 : 20 |

9.71 b±0.16 |

13.99b ±0.33 |

2.44b ±0.01 |

3.65b ±0.72 |

1.85 b±0.01 |

68.36 e±1.22 |

351.36 e±2.93 |

|

F |

0 : 50 : 25 : 25 |

10.34a±0.17 |

15.11a ±0.41 |

2.50a ±0.03 |

3.71a ±1.36 |

2.37 a±0.04 |

65.97 f±0.80 |

346.82 f±3.22 |

Table 1: Proximate composition (%) of cookies produced from malted millet, African walnut and unripe plantain composite flours.

Note: Values are mean ± SD of triplicate determinations, Means with different superscripts in the same column are significantly different (p<0.05). A=Cookies made from 100% wheat flour, B=Cookies made from 90% malted millet, 5% African walnut and 5% unripe plantain flours, C=Cookies made from 80% malted millet, 10% African walnut and 10% unripe plantain flours, D=Cookies made from 70% malted millet, 15% African walnut and 15% unripe plantain flour, E=Cookies made from 60% malted millet, 20% African walnut and 20% unripe plantain flours, F=Cookies made from 50% malted millet, 25% African walnut and 25% unripe plantain flours.

Mineral composition of millet-African walnut-unripe plantain composite cookie samples

The mineral composition of the cookie samples are presented in table 2. The levels of minerals: calcium, iron, zinc and phosphorus in the samples increased with increase in substitution with African walnut and unripe plantain flours except for magnesium and potassium which act as the major mineral elements present in millet grains. The calcium content of the samples ranged from 48.57 to 63. 76mg/100g. The control sample (100% wheat flour cookies) had the least value (48.57mg/100%), while the cookies substituted with 25% African walnut and 25% unripe plantain flours had the highest calcium content (63.76mg/100g). This is as an indication that African walnut has high calcium content [10]. Calcium is important in proper bone development in infants and young children. The iron content of the cookie samples varied significantly from each other. The cookies substituted with 25% African walnut and 25% unripe plantain flours the highest iron content (1.85mg/100g), while the control (100% wheat cookies) had the least iron content (1.25mg/100g). The increase is due to the fact that African walnut contains high amount of iron [10,34]. Regular consumption of food that is rich in iron has the potential to prevent anaemia in infants and young children. The phosphorus content of the cookie samples ranged from 157.87 to 170.71mg/100g. The control sample had the least phosphorus content (157.87mg/100g) while the cookies substituted with 25% African walnut and 25% unripe plantain flours had the highest value (170.71mg/100g). Phosphorus is an important nutrient that plays a significant role in the formation of Adenosine Triphosphate (ATP) in the body [35-37]. The potassium content of the cookie samples which ranged from 119.83 to 120.97mg/100g decreased slightly with increase in substitution with African walnut and unripe plantain flours in the samples. The decrease could be due to the reduction in the proportion of millet flour in the product. Potassium is essential in blood clotting and contraction of the muscles. The zinc content of the cookie samples varied from 1.49 to 1.83mg/100g with the control sample having the least value (1.49mg/100g). The increase in zinc content could be attributed to the substitution effect and this is in agreement with the report that unripe plantain is a good source of zinc [34]. Zinc supports normal growth and development during pregnancy, childhood and adolescence. It also stimulates the activities of vitamins in the formation of red and white blood cells [38], as well as in the proper functioning of the heart. The magnesium content of the samples decreased as the levels of substitution with African walnut and unripe plantain flours increased. There were significant (p<0.05) differences between the control sample and the composite flour cookies in magnesium content. The difference could be due to substitution effect [39]. Magnesium has the ability to reduce the incidence of migraine and heart attacks in humans. Minerals are essential for the maintenance of the overall mental and physical wellbeing and are also important constituents for the development and maintenance of bones, teeth, tissues, muscles, blood and nerve cells [40,41]. They also aid in blood clotting and maintenance of acid-base balance of the body [42]. The substitution of millet-based cookies with African walnut and unripe plantain flours greatly increase the calcium, iron, zinc and phosphorus contents of the products.

|

Sample ID |

% Substitution WF:MMF:AWF:UNPF |

Calcium

|

Iron |

Phosphorus |

Potassium |

Zinc |

Magnesium |

|

A |

100 : 0 : 0 : 0 |

48.57f±7.03 |

1.25 f±0.04 |

157.87 f±1.35 |

120.97 a±0.44 |

1.49 f±0.06 |

106.89 a±0.47 |

|

B |

0 : 90 : 5 : 5 |

53.26 e±14.16 |

1.31 e±0.09 |

167.86 e±0.13 |

120.46b ±0.11 |

1.56 e±0.17 |

106.87 a±0.47 |

|

C |

0 : 80 : 10 : 10 |

53.40 d±14.25 |

1.58 d±0.08 |

168.51 d±0.16 |

120.16 c±0.43 |

1.61 d±0.43 |

106.40 b±0.06 |

|

D |

0 : 70 : 15 : 15 |

58.45 c±7.06 |

1.65 c±0.04 |

168.73 c±0.12 |

120.15c ±0.43 |

1.71 c±0.16 |

106.31 c±0.09 |

|

E |

0 : 60 : 20 : 20 |

63.22 b±0.06 |

1.80 b±0.08 |

169.00 b±0.21 |

120.15 c±0.43 |

1.76 b±0.02 |

106.09 d±0.44 |

|

F |

0 : 50 : 25 : 25 |

63.76 a±0.03 |

1.85 a±0.01 |

170.71 a±0.66 |

119.83 d±1.26 |

1.83 a±0.04 |

105.38 e±0.76 |

Tables 2: Mineral composition (mg/100g) of cookies produced from malted millet, African walnut and unripe plantain composite flours.

Note: Values are mean ± SD of triplicate determinations, Means with different superscripts in the same column are significantly different (p<0.05). A=Cookies made from 100% wheat flour, B=Cookies made from 90% malted millet, 5% African walnut and 5% unripe plantain flours, C=Cookies made from 80% malted millet, 10% African walnut and 10% unripe plantain flours, D=Cookies made from 70% malted millet, 15% African walnut and 15% unripe plantain flour, E=Cookies made from 60% malted millet, 20% African walnut and 20% unripe plantain flours, F=Cookies made from 50% malted millet, 25% African walnut and 25% unripe plantain flours.

Force-deformation characteristics of millet-African walnut-unripe plantain composite cookie samples

The force- deformation characteristics of the cookie samples are presented in figure 1. The force- deformation characteristics of the composite cookies decreased significantly (p<0.05) with increase in substitution with African walnut and unripe plantain flours. The control (100% wheat cookies) exhibited better force- deformation characteristics compared to the composite cookies. The reduction could be due to the number of spaces created which tend to collapse on deformation. The observation is in close agreement with the report of Atuonwu and Akobundu [43], for wheat flour cookies supplemented with defatted pumpkin seed flour. It was also observed from the result that the force- deformation characteristics of the millet- African walnut- unripe plantain composite cookies decreased with increased substitution of African walnut flour. The decrease could be due to the increase in the percentage of fat ( 2.20-2.50%) with increase in percentage of African walnut flour added which in turn tend to dilute the levels of protein and carbohydrate in the samples which are principal compounds responsible for hardness in biscuits [1]. Millet flour cookies substituted with 25% African walnut and 25% unripe plantain flours had the least force- deformation characteristics. The force- deformation characteristics is principally determined in cookie technology to ascertain both their break strength and textural characteristics. In addition, the result also showed that the level of deformation of composite cookies increased gradually with increase in the application of compressive force compared to the wheat flour cookies. The observed increase in the level of deformation could be due to the presence of little amount of gluten in the composite flour components used for the production of cookies [1]. The force- deformation characteristics of cookies is important in that it helps to determine the type of packaging materials that can be used for packaging such products and as well predicts their shelf stability.

Figure 1: Force-deformation characteristics of cookies produced from malted millet, African walnut and unripe plantain composite flours.

Figure 1: Force-deformation characteristics of cookies produced from malted millet, African walnut and unripe plantain composite flours.

Note:

A=Cookies made from 100% wheat flour.

B=Cookies produced from 90% malted millet, 5% African walnut and 5% unripe plantain flours.

C=Cookies produced from 80% malted millet, 10% African walnut and 5% unripe plantain flours.

D=Cookies produced from 70% malted millet, 15% African walnut and 15% unripe plantain flours.

E=Cookies produced from 60% malted millet, 20% African walnut and 20% unripe plantain flours.

F=Cookies produced from 25% malted millet, 25% African walnut and 25% unripe plantain flours.

Sensory properties of millet-African walnut-unripe plantain composite cookie samples

The sensory scores of the cookies made from wheat flour and millet- African walnut- unripe plantain composite flours are shown in table 3. The result showed that all the samples had very high sensory ratings in all the attributes evaluated. The control sample (100% wheat cookies) was significantly (p<0.05) rated higher than all the test cookie samples for the attributes of colour, texture, crispness, taste, aroma and overall acceptability. The colour of the cookies darkened with increased substitution of African walnut and unripe plantain flours and the result is in agreement with the report of Sakyi-Dawson et al. [44], who observed that the colour of biscuits from a composite flour of cowpea and cassava darkened as the level of non-wheat flour supplementation increased from 30-55%. The colour change observed could be due to increased substitution and Maillard browning which is a reaction between amino acids of proteins and added sugar in the samples. The cookies made with 5-25% African walnut and 5-25% unripe plantain flours were generally acceptable. The increase in substitution with African walnut and unripe plantain flours resulted in decrease in acceptability as indicated by the lower scores of composite flour cookies compared to the wheat flour cookies. The cookies substituted with 25% African walnut and 25% unripe plantain flours were reported to have crumbly texture due to increased substitution of the composite flours. Panelists described the cookie made with 5% African walnut and 5%unripe plantain flours as having the best texture and crispness compared to the other test samples.

|

Sample ID |

% Substitution WF:MMF:AWF:UNPF |

Colour |

Texture |

Crispness |

Taste |

Aroma |

Overall Acceptability |

|

A |

100 : 0 : 0 : 0 |

7.35a±1.35 |

7.05 a±1.93 |

7.00 a±1.69 |

7.15 a±1.46 |

7.40a ±1.39 |

7.30 a±1.92 |

|

B |

0 : 90 : 5 : 5 |

7.15b±2.30 |

6.75 b±1.68 |

6.60 d±2.52 |

7.00b±1.86 |

6.70b±1.63 |

6.65b±1.90 |

|

C |

0 : 80 : 10 : 10 |

7.05c±1.99 |

5.85 c±1.69 |

5.50 c±1.95 |

6.60 c±2.27 |

6.35c±1.45 |

6.65b±1.50 |

|

D |

0 : 70 : 15 : 15 |

6.70d±1.22 |

5.50 d±2.06 |

5.30 d±2.00 |

6.50 d±1.88 |

6.25d ±1.45 |

6.45c ±1.50 |

|

E |

0 : 60 : 20 : 20 |

6.70d±1.22 |

5.00 e±2.06 |

5.10 e±1.99 |

6.20e±1.94 |

6.15e±1.79 |

6.35d±2.08 |

|

F |

0 : 50 : 25 : 25 |

6.20e±2.07 |

4.35 f±2.40 |

4.85 f±2.17 |

6.15 f±2.08 |

6.10 f±2.15 |

6.05e±1.96 |

Tables 3: Sensory properties of cookies produced from malted millet, African walnut and unripe plantain composite flours.

Note: Values are mean ± SD of triplicate determinations, Means with different superscripts in the same column are significantly different (p<0.05). A=Cookies made from 100% wheat flour, B=Cookies made from 90% malted millet, 5% African walnut and 5% unripe plantain flours, C=Cookies made from 80% malted millet, 10% African walnut and 10% unripe plantain flours, D=Cookies made from 70% malted millet, 15% African walnut and 15% unripe plantain flour, E=Cookies made from 60% malted millet, 20% African walnut and 20% unripe plantain flours, F=Cookies made from 50% malted millet, 25% African walnut and 25% unripe plantain flours.

Based on this result, the millet-African walnut-unripe plantain composite flours could be used to produce organoleptically acceptable cookies.

Conclusion

The study has shown that cookies of acceptable nutrient contents and sensory properties can be produced from composite flours of millet, African walnut and unripe plantain. It was also observed from the results that cookies produced from 100% wheat flour (control) were more acceptable organoleptically but the composite flour cookies were nutritionally superior to the control. The protein, fat, ash and crude fibre contents of the composite flour cookies were relatively higher than that of the control which is an indication that the addition of African walnut and unripe plantain flours greatly enhanced the levels of these nutrients in the samples. In addition, the substitution of wheat flour with African walnut and unripe plantain flours in the production of cookies greatly increased the calcium, iron, phosphorus and calcium contents of the products. The force-deformation characteristics of the cookies also showed that the degree of deformation of composite cookies increased gradually with increase in the application of compressive force compared to the control (100% wheat cookies). The increase in the level of deformation of composite cookies could be due to the presence of little quantity of gluten in the composite flour components (African walnut and unripe plantain flours) used for their production. The sensory properties of the samples equally revealed that the 100% wheat flour cookies used as control were the most acceptable to the panelists and also differed significantly (p<0.05) from the composite cookies in colour, texture, crispness, taste and aroma. This variation could be due to the unique quality of wheat flour in cookie production.

References

- Okaka JC, Isieh MI (1990) Development and quality evaluation of cowpea-wheat biscuits. Nigeria Food Journal 8: 56-62.

- Chinma CE, Gernah DI (2007) Physico-chemical and sensory properties of cookies produced from blends of Cassava, soybean and mango composite flour. Journal of Food Technology 5: 256-260.

- Akpapunam AM, Darbe JW (1994) Chemical composition and functional properties of blends of maize and bambara groundnut flour for cookie production. Plant Foods Hum Nutr 46: 147-155.

- Okoye JI, Obi CD (2017) Nutrient composition and sensory properties of wheat-African bread fruit composite flour cookies. Sky Journal of Food Science 6: 27-32.

- Ubbor SC, Akobundu ENT (2009) Quality characteristics of cookies from composite flours of watermelon seed, cassava and wheat. Pakistan Journal of Nutrition 8: 1097-1102.

- Ahmadou I, Gounga ME, Le GW (2013) Millets: Nutritional composition, some health benefits and processing-a review. Emirate Journal of Food and Agriculture 25: 501-508.

- Ahmed SM, Qing ZJC, Qum S (2013) Millet grains: Nutritional quality, processing and potential health benefits. Comprehensive Review in Food Safety 12: 281-295.

- Edem CA, Dosunmu I, Mirinda I, Bassey F (2009) Determination of proximate composition, ascorbic acid and heavy metal content of African walnut (Tetracarpidium Conophorum). Pakistan Journal of Nutrition 8: 225-226.

- Aviara NA, Ajikashile JO (2011) Effeect of moisture content and loading orientation on some strength properties of Conophor (Tetracarpidium Conophorum) nut. Journal of Agricultural Engineering Research 4: 4-11.

- Ayoola PB, Onawume OO, Faboya OO (2011) Chemical evaluation and nutritive values of Tetracarpidium conophorum (Nigerian walnut) seeds. Journal of Pharmaceutical and Biomdical Sciences 11: 1-3.

- Ogazi PO (1982) Plantain Utilization and Nutrition. In: Food Crops Production, Utilization, Nutrition. Nigeria Dotan Publication Ltd, Nigeria.

- Jideani VA (2005) Characteristics of local pearl millet (Pennistetum glaucum) grains. Nigerian Food Journal 23: 193-204.

- Barber LI, Obinna-Echem PC (2016) Nutrient composition, physical and sensory properties of wheat-African walnut cookies. Sky Journal of Food Science 5: 24-30.

- Okpala L, Okoli, EC, Udensi EA (2013) Physico-chemical and sensory properties of cookies made from blends of germinated pigeon pea, fermented sorghum and cocoyam flours. Journal of Food Science and Nutrition 1: 8-14.

- AOAC (2006) Official Methods of Analysis. Association of Official Analytical Chemists. (18th edn). Washington D.C, USA.

- Onwuka GI (2005) Food Analysis and Instrumentation: Theory and Practise. Naphtali Publishers Ltd, Lagos, Nigeria.

- Chauhan A, Saxena DC, Singh S (2015) Total dietary fiber and anti-oxidant activity of gluten free cookies made from raw and germinated amaranth (Amarantus Spp.) flour. LWT-Food Science and Technology 63: 939- 945.

- Echendu CA, Onimawo IA, Adieze S (2004) Production and evaluation of doughnuts and biscuits from maize-pigeon pea flour blends. Nigerian Food Journal 22: 147-153.

- Shahzadi N, Butt MS, Rehman SU, Sharif K (2005) Chemical characteristics of various composite flours. International Journal of Agriculture and Biology 7: 105- 108.

- Ndie EC, Nnamani CV, Oselebe HO (2010) Some physicochemical characteristics of defatted flours derived from African walnut (Tetracarpidium conophorum): An underutilized legume. Parkistan Journal of Nutrition 9: 909-911.

- Ekwe CC, Ihemeje A (2013) Evaluation of phytochemical properties and preservation of African walnut (Tetracarpidium conophorum). Academic Research International 4: 501-512.

- Hassan LG, Umar KJ (2006) Nutritional values of Balsam Apple (Monordica balsamine L.) leaves. Journal of Nutrition 5: 522-529.

- Enujiugha VN (2003) Chemical and functional characteristics of conophor nut. Pakistan Journal of Nutrition 2: 335-336.

- Romoke W (2009) Nutritional value of walnut. Daily Trust Newspaper, Nigeria.

- Kure OA, Bahago EJ, Daniel EA (1998) Studies on the proximate composition and effect of flour particle size on acceptability of biscuits produced from blends of soy beans and plantain flour. Namida Technology Scope Journal 3: 17-21.

- Eneche EH (1999) Biscuits making potential of millet-pigeon pea flour blends. Plant Foods Hum Nutr 51: 27-35.

- Ishiwu CN, Onyeji AC (2004) Properties of an instant gruel based on maize (Zea mays L) starch, African yam bean (sphenostylis stenocarper) flour and soybean (Glycine max) flour. Nigeria Journal of Nutitional Sciences 25: 16-19.

- Chukwu BN, Ezebuiro VO, Samuel ES, Nwachukwu KC (2013) Gender differential in the incidence of diabetes mellitus among the patients in Udi local government area of Enugu State, Nigeria. Mediterrenean Journal of Social Sciences 4: 131-138.

- Jaja T, Yarhere IE (2015) Risk factors for type 2 diabetes mellitus in adolescents secondary school students in Port Harcourt, Nigeria. Nigerian Journal of Paediatrics 42: 137-141.

- FAO/WHO (1994) Codex Alimentarius foods for special dietary uses including foods for infants and children. FAO, Rome, Italy.

- Ihediohanma NC, Durunma AI, Onuegbu NC (2009) Functional properties and performance of alum treated African bread fruit (Treculia africana) as a composite flour in cake production. Nigerian Food Journal 27: 159-167.

- Nzeagwu OC, Nwaejike NJ (2008) Nutrient composition, functional and organoleptic properties of complementary food formulated from sorghum, groundnut and crayfish. Nigerian Food Journal 26: 13-20.

- Okaka JC (2009) Handling, Storage and Processing of Plant Foods. Ocjanco Academic Publishers, Enugu, Nigeria.

- Adamu AS, Ojo IO, Oyetunde JC (2017) Evaluation of nutritional values of ripe, unripe, boiled and roasted plantain (Musa paradisical) pulp and peel. European Journal of Basic and Applied Sciences 4: 2059-3058.

- Badau MH, Nkama I, Jideani IA (2005) Phytic acid content and hydrochloric acid extractability of minerals in pearl millet as affected by germination time and cultivar. Food Chemistry 92: 425-435.

- Liang S, Yang G, Ma Y (2010) Chemical characteristics and fatty acid profile of foxtail millet bran oil. Journal of American oil Chemical Society 87: 63-67.

- Devi PB, Vijaybharathi R, Sathyabama S, Malleshi NG, Priyadarisini VB (2011) Health benefits of finger millet (Eleusine Coracana). polyphenol and dietary fibre: A review. J Food Sci Technol 51: 1021-1040.

- Claude B, Paule S (1979) The Manual of Natural Living. Biddles Limited Guildford, Surrey.

- Joseph A, Justice WA, Sssac A (2018) Anti-nutritional factors and mineral composition of pumpkin pulp and functional properties of pumpkin-wheat composite flour for bread preparation. Innovation Food Science and Technology 7: 1-9.

- Roth AR, Townsend CE (2003) Nutrition and Diet Therapy. Delmer Learning, Thompson learning Inc. Canada.

- Rolfes SR, Pinna, K, Whitney E (2009) Understanding Normal and Clinical Nutrition. Wardsworth Cengage learning, Canada.

- Wardkaw GM, Kessel M (2002) Perspectives in Nutrition. New Mcgraw Hill High Education, New York, USA.

- Atuonwu AC, Akobundu ENT (2010) Nutritional and sensory quality of cookies supplemented with defatted pumpkin (cuburbita pepo) seed flour. Pakistan Journal of Nutrition 9: 672-677.

- Sakyi-Dawson E, Lamptey JA, Johnson PNT, Annor GA, Budu A (2006) Effect of cowpea addition on quality and sensory characteristics of cassava-cowpea composite flour biscuits. African Journal of Food Science 1075-1076.

Citation: Ani EC, Okoye JI (2021) Nutrient Composition, Physical and Sensory Properties of Cookies Produced from Millet, African Walnut and Unripe Plantain Composite Flours. J Food Sci Nutr 7: 108.

Copyright: © 2021 Ani EC, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.