Optimization of Process Parameters for Healthy and Nutritious Instant Ready-to-Cook Black Soybean Dal Premix

*Corresponding Author(s):

Sweta RaiDepartment Of Food Science And Technology, G.B.Pant University Of Agriculture And Technology, Pantnagar, Uttarakhand, India

Tel:+91 9258058716,

Email:swetafoodtec@gmail.com

Abstract

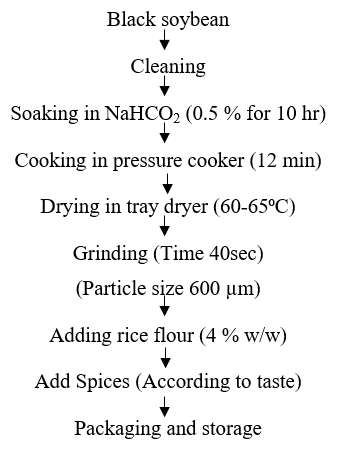

This study focuses on optimizing the process parameters for producing an antioxidant-rich, ready-to-cook black soybean dal, encompassing the stages of soaking, cooking, drying, and grinding. Black soybean seeds were soaked in aqueous solutions containing 0.5%, 1.0%, 1.5%, and 2.0% concentrations of NaCl and NaHCO3 separately, with soaking durations ranging from 2 to 12 hours at 30°C. Optimal soaking was achieved with a 0.5% NaHCO3 solution at 30°C for 10 hours. Subsequently, the soaked seeds underwent various cooking methods, including pressure cooking, microwave cooking, and open pan cooking, with time intervals of 4, 8, 12, 16, 20, 24, 28, and 32 minutes for each method. Pressure cooking was identified as the most effective method, requiring only 12 minutes and resulting in minimal solid loss (9.8%) and desirable texture/hardness (0.21kg). Post-cooking, the seeds were dried and coarsely ground, followed by the addition of 4% (w/w) rice flour to ensure consistency. The reconstituted product, mixed with water at a 1:4 ratio and seasoned with salt, turmeric, red chili, and coriander powder, achieved optimal sensory attributes with a reconstitution time of 7 minutes. Due to the presence of abundant anthocyanins and higher phenolic content in the seed coat, black soybean exhibited superior antioxidant properties compared to the yellow variety. This investigation aims to develop a cost-effective, nutritious ready-to-cook black soybean dal premix that is rich in antioxidants and offers enhanced protein, iron, calcium, essential fatty acids, and overall nutritional value.

Keywords

Antioxidant; Black soybean; Cooking time; Healthy; Ready-to-cook

Introduction

In recent decades, black soybean has gained popularity over the yellow variety due to its rich content of essential nutrients and bioactive compounds. While yellow soybeans are widely cultivated across India, black soybeans are traditionally grown on a smaller scale in regions such as Himachal Pradesh, the Kumaon Hills of Uttarakhand, Eastern Bengal, and the Khasi hills. Black soybeans are abundant in phenolic compounds, including phenolic acids, flavonoids, and lignin. These phytochemicals have significant health benefits, potentially aiding in the treatment of cancer, diabetes, cardiovascular diseases, and neurodegenerative disorders. Despite their ancient use in traditional remedies across China, Korea, Japan, Indonesia, and the Northwestern Himalayan region of India, the potential of black soybeans is often undervalued due to the less accepted black seed coat, limiting their cultivation and consumption to specific regions [1]. In comparison to other pulses, the black soybean has a higher protein level (32-43.6 %) and calcium content (387mg/100g). It also contains a superior level of unsaturated fatty acids, with a fat content of 15.5-24.7 per cent. Because of the presence of higher phenolic content in the seed coat, the antioxidant properties of black soybean are greater than the yellow variety. Anthocyanins are abundant in black soybean. Major anthocyanins, such as cyanidin-3-glucoside, delphinidin-3-glucoside, and pelargonidin-3-glucoside, have been extracted and identified from the seed coat of black soybean. The anthocyanins found in black soybeans have a variety of health benefits, including improving bone stability, lowering blood pressure, reducing cardiovascular problems, preventing cancer, lowering body weight, and having antibacterial properties. The richness of various nutritional and remedial bioactive compounds makes black soybean a wholesome food to be added to daily meals as supplement to cereal based diet. Mainly high amount of anthocyanins, minerals and less amount of fat makes black soybean as important and health promoting food. As it contains high amounts of antioxidants it is used as source of bioactive ingredients to overcome several health problems. Due to its tremendous health benefits it is considered as a treasure house of nutritional and medicinal properties. Though black soybean is nutritional and health promoting food, it is neglected legume at commercial level. The richness of various nutritional and remedial bioactive compounds makes black soybean a wholesome food to be added to daily meals. Underutilized black soybean is not much popular as yellow soybean. In the current market for consumers, very limited value-added products are available from black soybean. Due to higher cooking time and black color seed coat black soybean is not readily accepted by consumers. But this faces many challenges in the new lifestyle due to the longer cooking time and lots of preparation required. This premix is new value-added and ready to cook option for the consumer in cost effective manner.

Its cultivation is less capital intensive in nature and its ability to survive under harsh conditions particularly, in the event of failure of rain makes it a better choice than other competitive crops grown during rainy season in hills. High nutritional value and health promoting effects due to presence of various bioactive compounds make this legume as an excellent functional food crop and its consumption imparts various remedial benefits due to presence of plentiful amounts of natural pigment anthocyanin and flavonoid isoflavones in its seed coat and cotyledons respectively. There are no systematic studies on nutritional quality or health-enhancing qualities of black soybean value added products in the literature. Due to higher cooking time and black color seed coat black soybean is not readily accepted by consumers. But this faces many challenges in the new lifestyle due to the longer cooking time and lots of preparation required.

Hence, this study focuses to fill the gap in the existing knowledge because of the immense potential of black soybean to optimize soaking, cooking time for obtaining desirable texture and then to optimize blending ingredients for consumer acceptance. This premix is new value-added and ready-to-cook option for the consumer in cost effective manner.

Materials And Methods

Black soybean seeds were purchased from the local market and the seeds were cleaned of foreign material and stored in air tight containers at 25°C till further experimentation.

Physical Characteristics

Colour: For colour analysis the images were clicked Magnus Opto 1080x720p and the images were analysed using Image J image analysis tool. We obtained R,B,G values, were then transformed into L*,a*,b* using Colour Mine free library.

Thousand Grain Weight: The thousand grain weight was calculated as per Sumangala and Kulkarni [2].

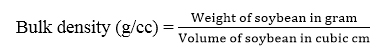

Bulk Density: The bulk density was calculated as per Mangaraj et al. [3], by adding 100g of seeds into 500ml measuring cylinders and the volume covered was recorded.

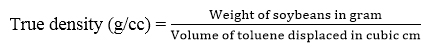

True Density: The true density was calculated as per Mangaraj et al. [3], by adding 100g of seeds into 500ml measuring cylinders containing 50ml toluene, the rise in volume was recorded.

True Density: The true density was calculated as per Mangaraj et al. [3], by adding 100g of seeds into 500ml measuring cylinders containing 50ml toluene, the rise in volume was recorded.

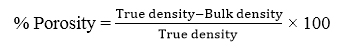

Percent Porosity: Porosity was calculated as:

Percent Porosity: Porosity was calculated as:

Seed Size (Length and Width): Seed length and width were recorded using a digital Vernier calliper (Indosaw, Osaw Industrial Products Pvt. Ltd. Haryana, India) and average values of length and width were expressed in millimeter.

Seed Size (Length and Width): Seed length and width were recorded using a digital Vernier calliper (Indosaw, Osaw Industrial Products Pvt. Ltd. Haryana, India) and average values of length and width were expressed in millimeter.

Proximate Characteristics: The Moisture content was determined as per AOAC [4], using a drying oven, the crude protein content was estimated using macro-Kjeldahlt method as per AOAC [4], using a conversion factor of 6.25, The crude fat content was determined using soxhlet extraction method as per AOAC [5], ash content was determined using muffle furnace as per AOAC [5], crude fiber was estimated as per the procedure described in Ranganna [6], and the carbohydrate content was computed by difference method.

Minerals: Calcium and iron in the samples were estimated using an atomic absorption spectrophotometer using wet-ashing procedure as described by Raghumulu et al. [7].

Total Polyphenols: Total phenols content was determined by Folin-Ciocalteu procedure given in which absorbance was measured at 765nm in a colorimeter against water blank.

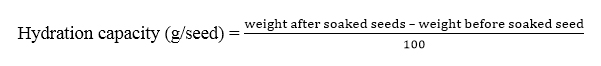

Hydration Capacity: The hydration capacity of the seeds was calculated as per Williams et al. [8]. 100 seeds were carefully weighed and soaked in 400 ml of soaking solution. After soaking, the seeds were drained of excess water and weighed.

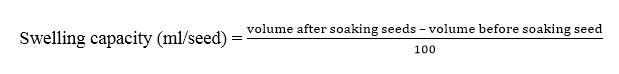

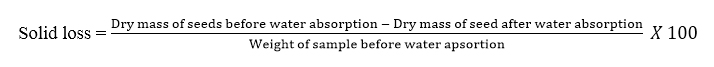

Swelling Capacity: Hundred soybean seeds were placed in a 100ml measuring cylinder containing 40ml soaking solution. The total volume was recorded. After soaking, the seeds were taken out and excess water was drained off. The volume of the seeds was taken by immersing the hydrated seeds in toluene.

Swelling Capacity: Hundred soybean seeds were placed in a 100ml measuring cylinder containing 40ml soaking solution. The total volume was recorded. After soaking, the seeds were taken out and excess water was drained off. The volume of the seeds was taken by immersing the hydrated seeds in toluene.

Instrumental Texture Analysis: The texture of cooked black soybean seed was analyzed using a stable microsystems TA.X T2i Texture analyzer with a 50kg cell load as described. The measurements were taken using a P/2 probe with pre-test, test and post-test speeds of 5.00mm/s, 0.20mm/s and 10.0mm/s respectively at a contact force of 5g and strain of 60 %.

Instrumental Texture Analysis: The texture of cooked black soybean seed was analyzed using a stable microsystems TA.X T2i Texture analyzer with a 50kg cell load as described. The measurements were taken using a P/2 probe with pre-test, test and post-test speeds of 5.00mm/s, 0.20mm/s and 10.0mm/s respectively at a contact force of 5g and strain of 60 %.

Solid Loss: The solid loss was determined by drying whole seeds at 105°C as described by Sayar et al. [9].

Results And Discussion

Physico-Chemical Parameters of Black Soybean Seed

According to table1, the physical characteristics like length, width and thousand grains weight of black soybean seeds were observed as 5.32±0.01mm, 2.33±0.02mm and 85.7±0.15g which were lower than the values stated by Dobhal and Raghuvanshi [10], the observed values were found to be lower denoting a smaller seed with respect to size, which may be due to the differences in variety whereas, Sumangala and Kulkarni [2], reported length, width and thousand grains weight to be 5.93mm, 4.23mm and 111.8g, which were higher than both the observations recorded in black soybean. The bulk density of black soybean was recorded 0.64±0.005g/ml which was similar to the value reported by Dobhal and Raghuvanshi [10]. The true density of black soybean (1.13±0.011g/ml) was also close to those of the yellow variety and was similar to those obtained by Harjai and Singh [11]. The porosity of the black soybean seeds was found 43±0.25 per cent. The results revealed that the physical characteristics of black soybean differed from those reported by the other authors which may be the reason for a smaller kernel size of black soybean resulting in a lower 1000 kernel weight and all other characteristics were similar to a significant level.

|

S. No. |

Parameters |

Black Soybean |

Literature Values |

References |

|

|

1 |

Length (mm) |

5.32±0.01* |

5.93±0.57* |

Sumangala and Kulkarni [2] |

|

|

2 |

Width (mm) |

2.33±0.02* |

4.23±0.57* |

Sumangala and Kulkarni [2] |

|

|

3 |

1000 grain weight (g) |

85.7±0.15* |

111.8±0.60* |

Sumangala and Kulkarni [2]; Dobhal and Raghuvanshi [10] |

|

|

4 |

Bulk density (g/cc) |

0.64±0.005* |

0.63 |

Dobhal and Raghuvanshi [10] |

|

|

5 |

True density (g/cc) |

1.13±0.011* |

1.16±0.01* |

Harjai and Singh [11]; Dobhal and Raghuvanshi [10] |

|

|

6 |

Porosity (%) |

43±0.25* |

44 |

- |

|

|

7 |

Colour |

L* |

24.40 |

- |

- |

|

a* |

0.89 |

- |

- |

||

|

b* |

-1.10 |

- |

- |

||

|

8 |

Moisture (%) |

9.71±0.015* |

7.10-12.00 |

Fetriyuna [12]; Ciabotti et al. [13]; Sumangala and Kulkarni [2] |

|

|

9 |

Crude Protein (%) |

43.77±0.026* |

30.00-48.60 |

Patel and Pandya [14]; Fetriyuna [12]; Ciabotti et al. [13]; Chen et al. [15]; Sumangala and Kulkarni [2] |

|

|

10 |

Crude fat |

17.87±0.05* |

15.50-21.46 |

Patel and Pandya [14]; Fetriyuna [12]; Ciabotti et al. [13]; Sumangala and Kulkarni [2] |

|

|

11 |

Crude fibre |

4.58±0.02* |

7.51-10.70 |

Patel and Pandya [14]; Ciabotti et al. [13] |

|

|

12 |

Ash |

5.91±0.03* |

4.20-6.70 |

Sharma et al. [16]; Zanetta et al. [17]; Fetriyuna [12]; Ciabotti et al. [13]; Sumangala and Kulkarni [2] |

|

|

13 |

Carbohydrate |

17.97 ±0.032* |

19.60-32.21 |

Patel and Pandya [16]; Fetriyuna [12]; Zanetta et al. [17]; Ciabotti et al. [13]; Sumangala and Kulkarni [2] |

|

|

14 |

Total polyphenols (mg/100 g) |

5.94±0.25* |

3.94-6.22 |

Choi et al. [18] |

|

|

15 |

Calcium (mg/100gm) |

256 ±0.25* |

201-307 |

Sumangala and Kulkarni [2] |

|

|

16 |

Iron (mg/100gm) |

13.02 ±0.02* |

10.31 -34 |

Sumangala and Kulkarni [2] |

|

Table 1: Physical and chemical parameters of whole black soybean seeds.

The black soybean seeds were found to have a low moisture content of 9.71%, a crude protein content of 43.77%, crude fat (17.87%), ash (5.91%), the calcium content of 256mg/100gm and iron was 13.02mg/100gm were found within the range reported by Chen et al. [15], and Sumangala and Kulkarni [2], and carbohydrate was 17.97% that is lower than the reported by Sumangala and Kulkarni [2]. Additionally, more radical scavengers/antioxidants in grain was found in black soybean due to the presence of higher amount of total polyphenols (5.94mg/100g) resulting in better quality. From the chemical composition, it was evident that the black soybean variety was higher in various major and minor nutrients making the black soybean nutritionally richer. These higher values make black soybean seeds a valuable asset from a nutritional aspect which can be utilized for the development of nutritionally rich value-added products.

Effect of Different Salts Concentration and Time of Soaking On Hydration Capacity and Swelling Capacity of Black Soybean

The effect of salts (NaCl and NaHCO3) used in different concentrations (0.5,1.0,1.5 and 2.0) for different soaking intervals (2, 4, 6, 8,10 and 12hr) on the swelling capacity and hydration capacity of the seeds was also observed and an initial increase in the salt concentration from 0.5 to 1% caused a significant decrease in the swelling capacity of the seeds irrespective of the type of salt used (Tables 2 & 3). However, any further increase in the salts concentration by 0.5% showed no significant change in the swelling capacity. But, an increase from 0.5 to 1.5 % and that from 1 to 2% showed a significant decrease in the swelling capacity and hydration capacity of the seeds. The type of salt was found to have a significant effect on both the hydration and swelling capacity of the seeds. The soaking solution containing NaHCO3 was found to have a higher hydration and swelling capacity. The highest swelling capacity of (0.119) in the seeds was observed in case of NaHCO3 at 10 hours and salt concentration of 0.5 % whereas, that for NaCl was only 0.108 at 0.5% after 10 hours. Same results were obtained for hydration capacity where the highest hydration capacity of 0.12 was observed in case of NaHCO3 at concentration of 0.5% after 10 hours, whereas that for NaCl was only 0.111 at 0.5% after 10 hours of soaking. The higher values of both hydration and swelling capacity in case of NaHCO3 may be due to the alkaline nature of the salt. As reported by Sievwright and Shipe [19], alkaline conditions changed the properties of native proteins, increasing their absorption, reducing steric hindrance, and exposing more peptide bonds to hydrolysis, at the same time, reducing calcium and magnesium-mediated interactions among phytic acid and protein, as well as minerals and pectin, altering the microstructure of beans, making them more porous and allowing easier heat and water penetration. The observed results were in accordance with Sastry et al. [20], who reported a positive relation of hydration capacity with seed swelling capacity. The soaking time was found to have a significant effect on the hydration and swelling capacity of the black soybean seeds. The hydration kinetics showed a significant increase in both the hydration and swelling capacity of the seeds with increase in the soaking time. The rate of increase in the hydration and swelling capacity of the seeds was found to be highest in the starting of the experiment and decreased gradually with the increase in time until the maximum hydration was achieved in 10 hours, after which the rate of increase in the hydration and swelling capacity went down. Eventually, no significant changes in the swelling and hydration capacity of the seeds were observed indicating the maximum achievable hydration and swelling capacity of the seeds was achieved. Lohani [21]; Ereifej and Shibli [22], also reported similar results indicating an increase in the hydration capacity of the seeds with increase in soaking time. The decrease in hydration rate was also reported by Pan and Tangratanavalee [23], who observed an initial instant rate of water absorption at the start after which the rate of water absorption gradually slowed down as the saturation moisture content was approached at all temperatures. This may be due to the fact that the force driving the water absorption into the seeds decreased as the rate of water absorption neared saturation moisture content [24]. However suggested that the saturation point will also depend on the temperature of the soaking solution and higher temperatures lead to the early reaching of the saturation point.

|

Swelling Capacity |

Hydration Capacity |

|

||||||||||||||

|

Concentration (%) |

Soaking Time (Hours) |

|||||||||||||||

|

2 |

4 |

6 |

8 |

10 |

12 |

Mean |

2 |

4 |

6 |

8 |

10 |

12 |

Mean |

C.D.0.05 For Swelling Capacity Time (T): 0.004 Concentration (C): 0.004 Interaction T × C: NS |

||

|

0.5 |

0.016 |

0.040 |

0.070 |

0.083 |

0.108 |

0.108 |

0.071 |

0.038 |

0.067 |

0.079 |

0.098 |

0.111 |

0.111 |

0.084 |

||

|

1.0 |

0.014 |

0.035 |

0.064 |

0.079 |

0.099 |

0.099 |

0.065 |

0.036 |

0.064 |

0.076 |

0.094 |

0.109 |

0.109 |

0.082 |

||

|

1.5 |

0.014 |

0.033 |

0.060 |

0.076 |

0.095 |

0.095 |

0.062 |

0.035 |

0.06 |

0.073 |

0.090 |

0.102 |

0.102 |

0.077 |

C.D.0.05 For Hydration Capacity Time (T): 0.005 Concentration (C): 0.004 Interaction T × C: NS |

|

|

2.0 |

0.013 |

0.031 |

0.056 |

0.071 |

0.092 |

0.092 |

0.059 |

0.035 |

0.059 |

0.072 |

0.090 |

0.100 |

0.100 |

0.076 |

||

|

Mean |

0.014 |

0.035 |

0.063 |

0.077 |

0.099 |

0.099 |

0.064 |

0.036 |

0.062 |

0.075 |

0.093 |

0.106 |

0.106 |

0.080 |

||

Table 2: Effect of NaCl on swelling capacity (ml/seed) and hydration capacity of black soybean.

|

|

Swelling Capacity |

Hydration Capacity |

|

||||||||||||

|

Concentration (%) |

Soaking Time (Hours) |

||||||||||||||

|

2 |

4 |

6 |

8 |

10 |

12 |

Mean |

2 |

4 |

6 |

8 |

10 |

12 |

Mean |

C.D.0.05 For Swelling Capacity Time (T): 0.004 Concentration (C): 0.004 Interaction T × C: NS |

|

|

0.5 |

0.018 |

0.040 |

0.069 |

0.097 |

0.119 |

0.119 |

0.077 |

0.04 |

0.068 |

0.089 |

0.107 |

0.12 |

0.12 |

0.091 |

|

|

1.0 |

0.015 |

0.038 |

0.066 |

0.094 |

0.112 |

0.112 |

0.073 |

0.038 |

0.068 |

0.088 |

0.103 |

0.111 |

0.113 |

0.087 |

|

|

1.5 |

0.015 |

0.035 |

0.062 |

0.092 |

0.110 |

0.110 |

0.071 |

0.037 |

0.065 |

0.085 |

0.100 |

0.110 |

0.11 |

0.084 |

C.D.0.05 For Hydration Capacity Time (T): 0.005 Concentration (C): 0.004 Interaction T × C: NS |

|

2.0 |

0.012 |

0.032 |

0.061 |

0.090 |

0.106 |

0.106 |

0.068 |

0.034 |

0.064 |

0.08 |

0.097 |

0.110 |

0.11 |

0.083 |

|

|

Mean |

0.015 |

0.036 |

0.065 |

0.093 |

0.112 |

0.112 |

0.072 |

0.037 |

0.066 |

0.085 |

0.102 |

0.113 |

0.113 |

0.086 |

|

Table 3: Effect of NaHCO3 on swelling capacity (ml/seed) and hydration capacity of black soybean.

Optimization of Ideal Cooking Method and Time for Preparation of Ready to Cook Black Soybean Dal

The process of cooking was carried out through three different methods viz, pressure cooking, microwave cooking, open pan cooking at a respective time range of 0-32 minutes. Then the observations were recorded for cooking time, solid loss and hardness.

The process of cooking was carried out through three different methods viz pressure, microwave and open pan cooking at respective time ranges of 0-32 minutes and the observations were recorded for cooking time, solid loss and hardness (Table 4). The results showed that among the various methods of cooking, open pan cooking method (at 1000C) did not cook the sample in the selected range of time and therefore, the microwave cooking (750Watts) of black soybean seeds was done for 28 min and the pressure cooking method (15psi at 1210C) took 12 min for cooking. If the samples of black soybean were beyond this duration, they were overcooked both in pressure cooking as well as microwave cooking. Results revealed that cooking time of seeds was significantly influenced by different types of cooking methods. We can clearly see that the solid loss (%) was minimum (2.7%) after 4 minutes of cooking using the pressure cooking method, but further advancement of cooking increased the losses to 12.10% after 16 minutes of cooking. After 12 minutes of cooking through pressure cooking the solid loss was 9.80%, and the sample was sufficiently cooked. But in case of microwave cooking, solid loss percent was 11.30% with sufficient cooking for 28 minutes, and it ranges from 1.90-13.40%. In the open pan cooking method, black soybean seeds were not cooked up given time range for cooking and solid loss percent varied from 1.80 to 12.26%. The amount of solid loss and its rate increased with increasing temperature as reported by [25,26]. Water was penetrating to the seed during soaking period and cooking solubilizes the proteins, polysaccharides, vitamins and minerals and leads them to be lost [26]. The effect of different cooking methods and cooking time on the hardness of black soybean was estimated with the help of a texture analyzer is presented in table 4. Results revealed that the cooking time of seeds was significantly influenced by different types of cooking methods. The hardness (kg) was maximum (0.66kg) after 4 minutes of cooking using the pressure cooking method, and thereafter, with the advancement of cooking time, it reduced to (0.16kg) after 16 minutes of cooking. After 12 minutes of cooking, the sample was sufficiently cooked and hardness was (0.21kg). But in case of microwave cooking, the hardness was 0.23kg due to sufficient cooking after 28 minutes and it ranged from 1.05-0.19kg. In open pan cooking, black soybean seeds were not fully cooked in the given time range for cooking and hardness of cooked seeds varied from 1.04-0.32kg. The results showed that cooking time was negatively correlated with the hardness. As the cooking time was increased, seeds become softer, also mentioned that seed hardness could be well correlated with the cooking time required. Among them, VRB-PS-453 and VS-157 (varieties/germplasm) of black soya beans were cooked earlier than other varieties as they exhibited the lowest hardness values. The effect of cooking time was found to be significant on both the solid loss and hardness of the black soybean seeds, irrespective of the type of cooking method used.

|

Cooking Methods |

|||||||||

|

Time (min) |

Pressure Cooking |

Microwave Cooking |

Open Pan Cooking |

||||||

|

Cooking Effect |

Solid Loss |

Texture Hardiness |

Cooking Effect |

Solid Loss |

Texture Hardiness |

Cooking Effect |

Solid Loss |

Texture Hardiness |

|

|

4 |

NC |

2.7 |

0.66 |

NC |

1.9 |

1.05 |

NC |

1.8 |

1.04 |

|

8 |

NC |

5.9 |

0.44 |

NC |

4.0 |

0.92 |

NC |

2.8 |

0.84 |

|

12 |

C |

9.8 |

0.21 |

NC |

6.6 |

0.57 |

NC |

4.4 |

0.73 |

|

16 |

OC |

12.1 |

0.16 |

NC |

7.27 |

0.47 |

NC |

6.35 |

0.58 |

|

20 |

- |

- |

- |

NC |

8.9 |

0.32 |

NC |

7.89 |

0.44 |

|

24 |

- |

- |

- |

NC |

9.8 |

0.28 |

NC |

8.7 |

0.36 |

|

28 |

- |

- |

- |

C |

11.3 |

0.23 |

NC |

10.98 |

0.34 |

|

32 |

- |

- |

- |

OC |

13.4 |

0.19 |

NC |

12.26 |

0.32 |

|

C.D. |

0.04 |

0.04 |

0.47 |

0.04 |

0.16 |

0.04 |

|||

|

SE (m) |

0.02 |

0.02 |

0.16 |

0.01 |

0.05 |

0.01 |

|||

|

SE (d) |

0.02 |

0.02 |

0.22 |

0.02 |

0.08 |

0.02 |

|||

Table 4: Effect of different methods of cooking and cooking time on the basis of hardness and solid loss in black soybean.

Optimized the Levels of Rice Flour to Maintain the Final Consistency of Ready to Cook Black Soybean Dal

The rice flour was used for cooking at various concentrations of 0-5% (w/w) i.e, treatments 1-6 and the samples were subjected to sensory evaluation on 9-point hedonic scale. The parameters selected for sensory evaluation were checked for appearance, texture and overall acceptability. The results pertaining to the sensory scores of the product sample after maintaining the viscosity with rice flour at various percentages are summarized in table 5. Four percent rice flour concentration gave the maximum score for appearance (8.61) and texture (8.10), and overall acceptability (8.36). An increase in the organoleptic scores of all the sensory parameters may be due to the mixing of rice flour with an increasing percentage giving thick consistency and increasing scores. However, beyond addition of 4% rice flour, a decrease in overall acceptability was observed.

|

Recipe |

Rice Flour (%) |

Viscosity (mPa.s) |

Appearance |

Texture |

Overall Acceptability |

|

1 |

0 |

344.80 |

5.03 |

5.04 |

5.04 |

|

2 |

1 |

797.90 |

6.50 |

5.67 |

6.09 |

|

3 |

2 |

955.50 |

7.50 |

6.49 |

7.00 |

|

4 |

3 |

1615.00 |

7.81 |

7.20 |

7.51 |

|

5 |

4 |

1812.00 |

8.61 |

8.10 |

8.36 |

|

6 |

5 |

3556.00 |

8.58 |

7.50 |

8.04 |

Table 5: Effect of rice flour on the viscosity and sensory parameters of ready to cook black soybean dal.

Optimization of Cooking Time and Preparation of Ready to Cook Black Soybean Dal

To optimize black soybean Dubke was used for cooking at various cooking time (3, 5, 7, 9, 11, 13 minutes) and the samples were subjected to sensory evaluation on nine-point hedonic scale. The parameter selected for sensory evaluation was checked and

The results pertaining to the sensory score of black soybeans Dal sample are summarized in table 6. The prepared final product reconstituted with water at 1:4 ratios and then cooked for different cooking time (3, 5, 7, 9, 11 and 13 minutes). The best time of cooking is evaluated based on sensory quality. Required amount of salt, turmeric, red chilli powder and coriander powder were added during final preparation of the product. After sensory evaluation, we found that cooking time of 7 minutes was appropriate for sensory scores i.e. 8.71 for appearance, 8.41 for consistency, 8.81 for texture, 8.91 for flavor and 8.71 for overall acceptability.

|

Sr. No. |

Characteristics |

Experimental Values Average±SD |

|

Optimized Product |

||

|

1 |

Moisture (%) |

6.4±0.13* (6.83)** |

|

2 |

Crude protein (%) |

38.6±0.18 (41.23) |

|

3 |

Fat (%) |

15.52±0.09 (16.58) |

|

4 |

Fiber (%) |

5.12±0.04 (5.47) |

|

5 |

Ash (%) |

5.69±0.35 (6.07) |

|

6 |

Carbohydrates (%) |

20.71±0.15 (22.12) |

|

7 |

Total polyphenols (mg/100g) |

3.95± 0.25 |

|

8 |

Calcium (mg/100g) |

278±1.14 |

|

9 |

Iron (mg/100g) |

8.38±0.24 |

Table 6: Chemical characteristics of optimized ready to cook black soybean dal.

Note: *SD stands for Standard Deviation

** Values in parenthesis indicates values on dry weight bas

The viscosity of final product which was cooked for 7 minutes was 1881 mPa.s. Our result is accordance with [27-32].

Flow Chart 1: Optimized process for preparation of ready to cook black soybean dal.

Flow Chart 1: Optimized process for preparation of ready to cook black soybean dal.

Conclusion

At the end of all the processes, the optimized product was found best in terms of soaking time and cooking time, but in terms of viscosity and sensory parameters (appearance, texture, and overall acceptability). Chemical composition of final standardized product (black soybean dal powder) were recorded 6.4±0.13 % moisture, 38.6±0.18 % crude protein, 15.52±0.09 % fat, 5.12±0.04 % fiber, 5.69±0.35 % ash, 20.71±0.15 % carbohydrates, 278±1.14mg/100g calcium and 8.38±0.24mg/100g iron and 3.95±0.25mg/100gm total polyphenols. The result of the present investigation reveals that standardization of the process for ready-to-cook traditional black soybean Dal can be prepared by adding 100g of black soya bean Dal powder, 400ml of boiling water and cooking for 7 minutes. This shows that black soybean can be successfully converted into a wonderful ready-to-cook black soybean Dal. This study conclude that preparation of optimized product is easier as compared to traditional preparation because of increase in urbanization and working women who need to prepare food that takes less time for cooking. The cost computation of the developed ready to cook premix with that of commercial Instant Dal premixes available it can be observed that the difference in costs of this premix is very low. This study emphasised to the suitability of black soybeans for potential value added products. Work needs to be done to popularise ‘black soybean’ to be used as a substitute in making nutritionally rich food as it has the potential to fulfil both food and nutritional security.

Acknowledgement

Authors are sincerely thankful to the Department of Food Science and Technology, G.B.Pant University of Agriculture and Technology, Pantnagar-263145, Uttarakhand, for granting all kind of support to aid this experiment.

Authors Contribution

Arun Prakash: Experimental work execution, product development, data analysis, manuscript writing and editing.

Sweta Rai: Conceptualization, methodology, validation, investigation, manuscript reviewing and editing, supervision.

Sabbu Sangeeta: Reviewing, validation and manuscript reviewing.

Preethi Ramchandran: Reviewing, validation and manuscript reviewing

Satish Kumar Sharma: Methodology, data analysis and manuscript reviewing.

Anil Kumar: Methodology, validation and manuscript reviewing.

Santoshi Rawat: Product development and reviewing.

Poonam Yadav: Product development and reviewing.

Neha Jakhmola: Product development, reviewing and editing.

Referances

- Dukare MP, Rai S, Sangeeta S, Ramachandran P, Yadav P, et al. (2024) Comparative study on Uttarakhand’s indigenous black soybean variety (Bhat) for tofu production. Asian Journal of Dairy and Food Research.

- Sumangala S, Kulkarni UN (2019) Physico-chemical properties of black and yellow soybean (Glycine max L.) Genotpe. J Pharm Innov 8: 33-37.

- Mangaraj S, Agrawal S, Kulkarani SD, Kapur T (2005) Studies on physical properties and effect of pre-milling treatments on cooking quality of pulses. J Food Sci Technol 42: 258-262.

- AOAC (1995) Official methods of analysis of AOAS International. (1995) The University of Wisconsin-Madison, Washington DC, USA.

- AOAC (1986) Official Methods of Analysis of the Association of official Analytical Chemist. Washington DC, USA.

- Ranganna S (2005) Handbook of Analysis and Quality Control for Fruit and Vegetable Products. McGraw-Hill, New Delhi, India.

- Raghumulu N, Nair KM, Kalyansundaram S (2003) A manual of laboratory techniques. Nine, India.

- Williams PC, Nakoul H, Singh KB (1983) Relationship between cooking time and some physical characteristics in chickpeas (Cicer arietinum L.). J Sci Food Agric 34: 492-496.

- Sayar S, Turhan M, Köksel H (2009) Solid loss during water absorption of chickpea (Cicer arietinum). J Food Process Eng 34: 1172-1186.

- Dobhal N, Raghuvanshi RS (2018) Physical characteristics and effect of germination on functional properties of black soybean (Glycine max). Asian J Dairy Food Res 37: 56-60.

- Harjai N, Singh G (2007) Evaluation of different soybean varieties for manufacture of soy milk. Int J Food Sci Technol Nutr 2: 71-77.

- Fetriyuna F (2015) The potential of darmo black soybean varieties as an alternative of a promising food for future. Int J Adv Sci Eng Inf Technol 5: 44-46.

- Ciabotti S, Silva ACBB, Juhasz ACP, Mendonca CD, Tavano OL, et al. (2016) Chemical composition, protein profile and isoflavones content in soybean genotypes with different seed coat colors. Int Food Res J 23: 621-629.

- Patel KD, Pandya AV (2014) Assessment and biochemical analysis of black soybean (with and without seed coat). World J Pharm. Res 3: 4272-4278.

- Chen Z, Wan J, Liu W, Chen H (2017) Physicochemical characterization, antioxidant and anticancer activities of proteins from four legume species. J Food Sci Technol 54: 964-972.

- Sharma S, Kaur M, Goyal R, Gill BS (2014) Physical characteristics and nutritional composition of some new soybean (Glycine max ) genotype. J Food Sci Tech 51: 551-557.

- Zanetta CUB, Waluyo A, Rachmadi M, Kurniawan (2015) Oil content and potential region for cultivation black soybean in java as biofuel Energy Procedia 65: 29-35.

- Choi YM, Yoon H, Lee S, Ko HC, Shin MJ, et al. (2020) Isoflavones, anthocyanins, pheolic content and antioxidant activities of black soybean (Glycine max (L.) Merrill) as affected by seed weight. Sci Rep 10: 19960.

- Sievwright CA, Shipe WF (1986) Effect of storage conditions and chemical treatments on firmness, in vitro protein digestibility, condensed tannins, phytic acid and divalent cations of cooked black beans (Phaseolus vulgaris). J Food Sci 51: 982-987.

- Sastry DVSSR, Upadhyaya HD, Srinivas TR (2019) Variation for seed physical and hydration properties of chickpea (Cicer arietinum) mini core collection and their relevance to conservation and utilization. Plant Genet Res 10: 1-14.

- Lohani K (2000) Evaluation od different lentil varieties for physic-chemical, cooking and product manufacture characteristics. Thesis, Master of Science. G.B. Pant University of Agriculture & technology, Pantnagar, India.

- Ereifej KI, Shibli RA (1995) Physical, chemical and cooking characteristics of a ‘Landrace’ and three newly developed lentil cultivars grown in Jordon. J Food Sci Technol 32: 27-30.

- Pan Z, Tangratanavalee W (2003) Characteristics of soybeans as affected by soaking conditions. LWT-Food Sci Tech 36: 143-151.

- Kashiri M, Kashaninejad M, Aghajani NJLA (2010) Modeling water absorption of sorghum during soaking. Latin American Applied Res 40: 383-388.

- Kon S, Wagner JR, Booth AN (1974) Legume powders: preparation and some nutritional and physicochemical properties. J Food Sci 39: 897-899.

- Kon S (1979) Effect of soaking temperature on cooking and nutritional quality of beans. J Food Sci 44: 1329-1335.

- Sayar S, Gupta A, Mahajan V, Kundu S, Gupta HS (2007) Physicochemical and nutritional attributes in 20 black soybean lines (Glycine Max) Of Himalayan region India. J Food Qual 31: 79-95.

- Agarwal DK, Billore SD, Sharma AN, Dupare BU, Srivastava SK (2013) Soybean: Introduction, improvement and utilization in India-problems and prospects. Agric Res 2: 293-300.

- Hipparagi Y, Singh R, Choudhury D R, Gupta V (2017) Genetic diversity and population structure analysis of Kala Bhatt (Glycine max Merrill) genotypes using SSR markers. Hereditas 154: 1-9.

- Hoffman JR, Falvo MJ (2004) Protein - Which is Best? J Sports Sci Med3: 118-130.

- Rizzo G, Baroni L (2018) Soy, soy foods and their role in vegetarian diets. Nutrients 10: 43.

- SOPA (2021) The soybean processors association of India.v

Citation: Prakash A, Rai S, Sangeeta S, Ramachandran P, Sharma SK, et al. (2024) Optimization of Process Parameters for Healthy and Nutritious Instant Ready-to-Cook Black Soybean Dal Premix. J Food Sci Nutr 10: 186.

Copyright: © 2024 Arun Prakash, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.