Physiochemical Properties of Composite Cookies Made from Un-Rip Plantain, Groundnut Flour and Sesame Seeds Influenced by Blend Variation

*Corresponding Author(s):

Ogori AFDepartment Of Food Science And Technology, Federal University Of Agriculture Makurdi, Nigeria

Email:Ogorifaraday@gmail.com

Abstract

Cookies are easy and convenience food and is becoming increasingly popular. Composite cookies made from unripe plantain, ground nut flours and sesame seeds influenced by blend variations are scarce. The results revealed that functional properties significantly differ (p<0.05) across samples. The mineral potassium, Magnesium, vitamin C and β-carotene with sesame seeds increased as unripe plantain flour ratio decreased and when ground nut flour ration remain constant, and this blending influenced the protein content, moisture, ash, fat, fiber, and carbohydrate content of the cookies. Decreasing unripe-plantain flour and increasing sesame amounts decreases bulk density, swelling index water absorption and foaming capacities. Across the blends, the weight, diameter and spread ration increased as the supplementation level increased but cookies thickness decreases. The 10% groundnut flour and 30% of sesame seed incorporations seems utilizable for making cookies based on the functional result. Decreasing unripe plantain flour and increasing sesame seeds amounts confers this made cookie acceptance in appearance, aroma, texture, taste, and general scores.

Keywords

Attributes; Flour; Functional properties; Groundnut; Quality; Sensory; Sesame seed; Unripe Plantain

Introduction

The increase in consuming functional foods because of health-related issues is on the rise, such as Celiac disease, diabetes, and hypertension. Recently, WHO recommendation is to reduce the consumption of carbohydrate foods [1]. Newer information on nutrition is the recommendation to consume low-carbohydrate diets, including slowly digested food products, as well as an increased intake of functional foods [2]. Cookies are ready to eat food, convenient and inexpensive to prepare usually from unpalatable dough. Though, cookies are confectionery product made to a very low moisture content [3] when favorably compared to biscuits, they are large with softer chewing texture (IFIS, 2005) and are consumed extensively as a snack food and on a large-scale developing country like Africa [4]. They can serve as vehicle for delivery of bio nutrients or functional meals when readily available. This partly stimulated the research into the production of cookies using these ingredients containing functional nutrients. Considering the health attributes derivable from unripe plantain, sesame seed and groundnut flour, their addition as composite blends in the preparation of cookies may result in co-functional cookies and this may enhance the nutritional and health status of the consumers, reduce total dependence on wheat flour and prevent incidence of celiac diseases surging into our society. Work on composite flour in cookies production has been opined [5-11].However, no composite cookies has been reported from un-rip plantain, groundnut flour and sesame seed flours. This work seeks to establish functional cookies from un-rip plantain flour, groundnut and sesame flour to alleviate hidden hunger and salient nutritional diseases flooding Africa countries today.

Materials And Methods

Ingredients includes the five bunch of unripe plantain, two cups of sesame seeds, three cups groundnut, and other baking ingredients includes; (butter, salt, sugar, baking powder and egg) were obtained from modern market Benue state, Nigeria.

Preparation of unripe plantain flour

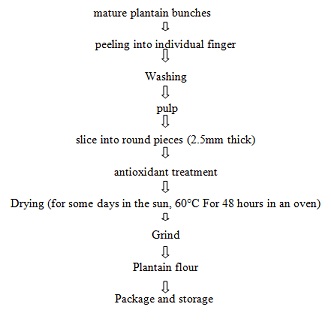

In preparation of unripe plantain flour [12] method was adopted. Briefly, matured unripe plantain was washed and hand peeled, and the edible portion (pulp) was sliced into sizes (6.0 x 4.0 cm). The slices were immersed in 0.25 g L sodium metabisulphite at 30°C for 10 min. The slices were then dried at 60°C in an air-draft oven (Gallenkamp 300 plus series, England) and then ground into flour using attrition mill (Globe P 44, China). The flour samples were passed through a 0.45 mm mesh size sieve to obtain the flour and stored in plastic containers with lids at 4°C in a refrigerator from where samples were drawn for analysis (Figure 1).

Figure 1: Flow chart for Plantain Flour Production.

Figure 1: Flow chart for Plantain Flour Production.

Groundnut flour preparation

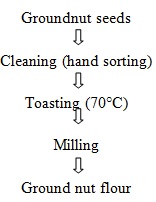

The groundnuts were sorted and cleaned to remove dirt and roasted at 70°C. The roasted groundnut was then milled using a hammer mill as shown in figure 2 and stored in plastic container at 4°C in a refrigerator.

Figure 2: Flow chart for the Preparation of Groundnut Flour.

Figure 2: Flow chart for the Preparation of Groundnut Flour.

Preparation of sesame seed

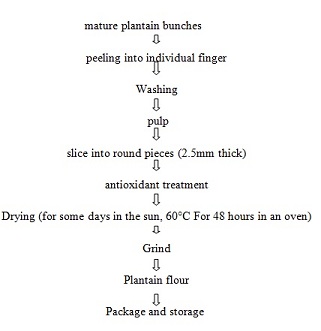

Dehulled sesame seed was sorted to remove foreign materials and there after soaked for five minutes to enable dehulling. The dehulled seed was washed in cold tap water and dried at 60°C in an air- oven (Gallenkamp 300 plus series, England (Figure 3). They were later tied in airtight polyethylene high density and stored at ambient temperature (Table 1).

Figure 3: Flow chart for the Preparation of Groundnut Flour.

Figure 3: Flow chart for the Preparation of Groundnut Flour.

|

Sample/ blend recipe ratio |

PF |

SS |

GNF |

Veg fat |

sugar |

egg |

Baking powder |

Salt |

water |

|

A100:0:0 |

300 |

0 |

0 |

100 |

100 |

1 |

10 |

1.5 |

15 |

|

B90:10:0 |

270 |

0 |

30 |

100 |

100 |

1 |

10 |

1.5 |

15 |

|

C80:10:10 |

240 |

30 |

30 |

100 |

100 |

1 |

10 |

1.5 |

15 |

|

D70:10:20 |

210 |

60 |

30 |

100 |

100 |

1 |

10 |

1.5 |

15 |

|

E60:10:30 |

180 |

90 |

30 |

100 |

100 |

1 |

10 |

1.5 |

15 |

Table 1: Sample and blend recipe ratio for composite cookies production.

Key: Plantain flour, SS= sesame seed, GNF=groundnut flour; Source; [13]

Cookies preparation

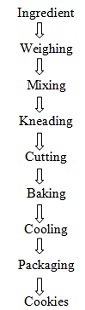

Fat and sugar, flour, baking powder, eggs and salt were manually mixed in a bowl to form dough. The dough was rolled and cut to a uniform diameter of %-mm using a cookie cutter and baked in an oven at 165°C for 20 min. The cookies were then removed and allowed to cool on a rack and packaged in low density polyethylene bags and kept in a plastic container at ambient temperature 30+ 1°c for 2hrs for further analysis. The flow chart for cookie production is shown in figure 4.

Figure 4: Flow Chart to produce Cookies Source: [14].

Figure 4: Flow Chart to produce Cookies Source: [14].

Blend functional property

Water and Oil absorption capacity (WAC/FAC)

The water and oil capacity of the flour blends were determined as described. About 1g of the cookies sample was weighed into conical graduated centrifuge tube. Using a warring mixer, the sample was thoroughly mix with 10ml of distilled water or and oil for OAC, all in a centrifuge tube for 30mins. The sample was allowed to stand for 30minutes at room temperature and then centrifuged at 1600rpm for 30mins. The volume of free water or oil was read directly from the graduated centrifuge tube

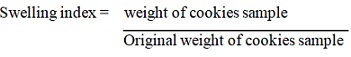

Swelling index

The swelling index was determined using the method. A 5g of the cookies sample was weighed into a 100ml graduated cylinder with the dry bulk volume noted. 100ml of hot water at 70°c was mixed. The volume after 10-15mins was recorded and calculated as

Bulk density

The tulk density was determined using the method described by Onwuka, (2005). 2g of sample was filled in a 10ml graduated cylinder its bottom tapped on laboratory bench until there is no further decrease in volume of cookies sample. The volume was taken, and density calculated as.

Determination of foam capacity

Determination of foam capacity

The foam capacity was determined by the method described by [13] with slight modification. The lg flour sample was added to 50ml water at 30+2°C in a graduated cylinder. The suspension was mixed and shaken for 5 minutes to foam. The volume of foam at 30s after whipping was expressed as foam capacity using the formula

Proximate analysis of cookies

Proximate analysis of cookies

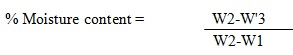

Moisture content determination

An evaporating crucible was washed and dried in oven for 30 minutes at 105°C.It was cooled in a desiccator for 30 minutes and weighed as (W). Each of 4.00 g (W2) samples was weighed in three crucibles separately. The weighted crucibles were then placed in the oven for one hour at 105°C, then cooled, weighed, and transferred back to the oven and cooled and weighed again until a constant weight (W3) is achieved. The result was expressed as percentage of the weight of the moisture lost over original weight of samples.

WI=Weight of crucible,

WI=Weight of crucible,

W2=Weight of crucible plus sample,

W3= Weight of crucible plus sample after drying

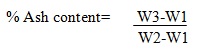

Ash content determination

The crucible was weighed using analytical balance as (Wi). 3g of sample was weighed separately into three crucibles and labelled (W2). It was then transferred to a furnace maintained at a temperature of 550°C for three hours for complete decarbonization to obtain white ash. The crucible and ash were cooled in a desiccator and weight as (W3). The result was expressed as percentage of the weight of ash over the original weight of the starch sample. That is:

W1 = Weigh of crucible,

W1 = Weigh of crucible,

W2- weigh of crucible and sample,

W3-weight of crucible and ash

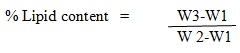

Fat content determination

A 250.0 ml round bottom flask was washed, dried, and weighed as (W1). The thimbles were weighed as (W2). The sample was wrapped in moisture-free filter paper and placed in a thimble which was then plugged with cotton wool. 400ml of petroleum spirit (40-60°C) was added to the sample in the thimble and allowed to reflux into the round bottom flask The Soxhlet apparatus was set up and allowed the extraction to continue for six hours. After the extraction, the solvent was distilled off on a water bath and the weight as (W3) of the flask was noted and the result was expressed as:

W1-weight of flask,

W1-weight of flask,

W2=weight of sample,

W3=weight of the flask plus oil

Protein content determination

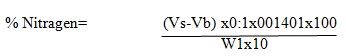

Two grams (2.g) sample and 8.0g of catalyst mixture were transferred into a Kjeldahl digestion tube and .20 ml of concentrated sulphuric acid was added and the mixtures was heated in an inclined position. Heating with continuous until a clear mixture was seen. The mixture was allowed to cool and diluted with distilled-deionized and made up 100ml standard volumetric flask using distilled water. The digested samples were distilled and then 10 ml of 10 M NaOH and 5 ml of 4% boric acid with two drops of mixed indicator (Indirect Titration method) with the aid of kjeldah apparatus into 25ml conical flask. The distillate was titrated with 0.IM HCL solution to pink end point. Percentage nitrogen and crude protein was calculated as:

Where Vs and Vb are titre value of sample and titre value of blank respectively

Where Vs and Vb are titre value of sample and titre value of blank respectively

Crude Protein = 6.25x% Nitrogen

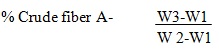

Crude fiber content determination

Three (3g) weight of the defatted cookies sample was placed in a bottom flask containing having 200 ml of 0.13 M sulphuric acid and the mixture refluxed for 30 minutes. The solution was filtered washed with boiling water. The residue was transferred to a beaker and boiled for 30 minutes with 200 ml 0.313 M NaOH. The residue was washed with 50 ml acetone to remove traces of oil and placed in a crucible and weighed as (W2). This was then dried in the oven at 105°C for one hour and then incinerated in the furnace at 550°C for three hours. The result is expressed as percentage of crude fiber as given below:

W1-weight of crucible,

W1-weight of crucible,

W2-weight of sample plus crucible,

W3-weight of ash plus crucible

Carbohydrate content determination

The carbohydrate content was expressed as the total carbohydrate by difference. Thus % Carbohydrate = 100 - (Moisture +Protein +Ash +Fibre +Protein)

Physical Properties of Cookies

The physical quality of the cookies was carried out according to the method of [14].

Determination of cookies Weight

The cookies were selected randomly, and the weight of the cookies was measured using an analytical balance.

The thickness

The thickness was determined in mm using screw gauge.

The Diameter

The diameter was determined in mm using vernier caliper.

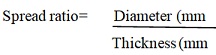

The Spread ratio

The spread ratio was calculated as a ratio of diameter to thickness  Sensory evaluation of cookies

Sensory evaluation of cookies

The cookie samples were evaluated by a panel of fifteen judges from the University of Agriculture Makurdi, for attributes of the color, texture, aroma, taste and general acceptability on a 9-point scale for strongly dislike and 9 for strongly like.

Statistical Analysis

All determinations were conducted in duplicate. Data generated was subjected to analysis of variance (ANOVA). The means were tested using LSD and Means separated by 5% probability level.

Results and Discussion

Functional properties of cookies

The functional properties of the composite flour are given in Table 2. High bulk density was observed in the flour blends of 90:10:0 while the least recorded in 60:10:30 blend ration with value of 0.833g/ml. The present study revealed that bulk density of cookies flour could be an advantage in the formulation of supplementary food [15]. While the relative high bulk density of the flour blends indicates that packaging could be economical as reported. However, the swelling capacity of flour cookies depends on the processing approach adopted; the bulk density ranged from (0.833-0.910g/ml). Water absorption capacity ranged from (1.37% - 1.87%) but blend ration of 80:10:10 have no significant different and had the highest mean score of (1.87%) while the least was recorded in 60:10:30 blend ration of (1.37%). Water absorption capacity represents the ability of a product to imbibe or associate with water molecules. Similarly, the value of oil absorption capacity was observed in 80:10:10 blend with a mean score of 1.28% while the least value was recorded in 60:10:30 (0.827%). The water and oil binding capacity of these cookies samples blends suggests a good blend mix. Foam capacity ranged from 0.203% -1.960%) with 90:10:0 blend ration having mean score of (1.960%) while the least was recorded in 60:10:30 at 0.203%. The higher foaming capacity in cookies blends of 90:10:0 could be due to high protein present in groundnut flour. The foam stability decreased with increase in the addition of groundnut and sesame seeds. This suggests that cookies with much plantain flour blends is more stable, hence foams are used to improve texture, consistency and appearance of the foods.

|

Sample PF:GF:SS |

Bulk Density |

Swelling Index |

Water Absorption capacity |

Oil absorption capacity |

Foaming capacity |

|

A100:0:0 |

0.91a+_0.01 |

3.33b+_0.06 |

1.87a+_0.15 |

1.00b+_0.01 |

1.13b+_0.21 |

|

B90:10:0 |

0.90a_0.03 |

3.43d+_0.06 |

1.87a+_0.06 |

1.01b+_0.01 |

1.96a+_0.00 |

|

C80:10:10 |

0.87ab+_0.01 |

2.83c+_0.06 |

1.80a+_0.00 |

1.28a+_0.01 |

0.31d+_0.01 |

|

D70:10:20 |

0.87b+_0.00 |

2.23b+_0.06 |

1.37a+_0.06 |

0.83c+_0.01 |

0.59c+_0.01 |

|

E60:10:30 |

0.83b+_0.06 |

2.20a+_0.00 |

1.47a+_0.06 |

0.83d+_0.01 |

0.203d+_0.01 |

|

LSD |

0.06 |

0.09 |

0.15 |

0.01 |

0.17 |

Table 2: Functional properties of Composite cookies.

Values are mean+_ standard deviation of three readings. Values with same superscript within the same column are not significantly different at P- value (0.05)

PF= Plantain flour, SS= sesame seed, GNF=groundnut flour

Proximate compositions of cookie samples

The result of the proximate analysis is presented in Table 3. Protein content of the cookies was significantly different (14.16%) and the blend 60:10:30 had the highest mean percentage protein content while the least was recorded for 100:0:0 blend, with percentage mean value of 11.20%. The result implies that cookies from blended samples were high in protein content and could be used as alternative protein source in protein deficiency wheat-based cookies. Population consuming these snacks will therefore benefit. Sample blend 100.0.0 was significantly higher (P<0.05) in terms of moisture content. It has the highest percentage moisture content of 7.64% while the least value was recorded for blend 90:10:0 with 3.63%. The moisture content hence, ranged between (3.63% -7.64%). These values were minimal and may not have adverse effect on the quality attributes of the product as the values were below the 10% moisture level recommended for safe shelf keep of product (SON 2007). The low moisture content values observed in this study will also increase the shelf life of the product [16]. Reported that the moisture content of different cookies vary according to the type of cookies produced. Cream crackers cookies have about 4.3% moisture while digestive cookies have about 4.5%. There was significant difference (p<0.05) in the fat content of the cookie E60:10:30 with higher value of 14.73% while the least value was recorded for sample A with 7.67%. The fat and oil content of groundnut and sesame seed which are 46% and 50.1- 51.7% respectively may have contributed substantially to its high fat content [17]. Have reported 20.50% fat content in digestive biscuit. Fat plays an important role in determining the shelf life of food products but at a relatively high fat content could be undesirable in baked food products. This is because fats can promote rancidity in food, leading to development of unpleasant and odorous compounds [18]. Also, diet high in fats predisposes consumers to different illness such as obesity, coronary heart diseases [19]. There was also a significant difference (p<0.05) in the fiber content of 80:10:10 with mean score of 0.46% while the least score was recorded in 60:10:30 at 0.021%. Fibre in food facilitates easy digestion in the colon and reduces constipation [20]. There was significant difference (p<0.05) in the ash content of the cookie samples. 60:10:30 had the highest mean score of 6.01% while the least mean value was recorded in 70:10:20. the presence of ash is an indication of minerals present in the sample [20]. Ash is a non-organic compound contains mineral, content of food and nutritional, its aids in the metabolism of other organic compounds such as fats and carbohydrate [21]. 100:0:0 was significantly higher (p<0.05) with 69.61% in the carbohydrate content while the least value was recorded in 60:10:30 with 60.24% which implies that the cookies are rich in carbohydrates source according to [22], the higher the protein, fat, ash content, the less the carbohydrate. Cookie is an energy food which is taken mostly in between meals by both young and old [23].

|

Sample PF:GF:SS |

Moisture |

protein |

Fat |

Crude Fibre |

Ash |

Carbohydrate |

|

A100:0:0 |

7.64a+_0.59 |

11.20c+_0.14 |

7.67d+_0.10 |

0.31b+_0.01 |

3.57d+_0.14 |

69.61a+_0.69 |

|

B90:10:0 |

3.63c+_0.03 |

12.42d+_0.11 |

11.61b+_0.30 |

0.42a+_0.01 |

4.83c+_0.05 |

67.09b+_0.48 |

|

C80:10:10 |

3.74c+_0.04 |

12.85c+_0.23 |

12.58b+_0.05 |

0.046ac+_0.01 |

4.89c+_0.14 |

65.89c+_0.36

|

|

D70:10:20 |

4.83b+_0.03 |

13.48b+_0.04 |

14.39a+_0.07 |

0.036cd+_0.01 |

5.23b+_0.01 |

62.05d+_0.02 |

|

E60:10:30 |

4.84b+_0.02 |

14.16a+_0.08 |

14.73a+_0.04 |

0.02d+_0.001 |

6.01a+_0.003 |

60.24c+_0.04 |

|

LSD |

0.69 |

0.34 |

0.40 |

0.02 |

0.22 |

1.05 |

Table 3: Proximate Composition of Composite cookies.

Values are mean+_ standard deviation of two replications. Values with same superscript within the same column are not significantly different at P- value (0.05 PF =Plantain flour, SS= sesame seed, GNF=groundnut flour

Micronutrients contents of cookies

The result of the micronutrient contents of cookies samples are presented in Table 4. Ascorbic acids ranged from (2.50 to 4.25 mg/100g), B-carotene ranged from (2.25 to 2.33mg/100g) , Magnesium (0.112 to 0.554 mg/g) and potassium (0.033 to 0.093 mg/100 g) respectively. The potassium and magnesium contents of composite cookies were significantly (p<0.05) higher than the control cookies while B- carotene and Ascorbic acids content of composite cookies were not significantly (p<0.05) different from the control. Addition of sesame seed and groundnut flour to plantain flour increased the micronutrients content of the cookies. The higher contents of potassium and magnesium in composite cookies than 100% plantain flour inclusion cookies may be attributed to high contents of potassium and magnesium in plantain and sesame seeds. The high potassium and magnesium content of the cookies make them suitable as a nutrition therapy for hypertensive and diabetic patients from the functional roles these minerals flour could play.

|

Sample PF:GF:SS |

Vitamin C (mg/100g) |

B-carotene (mg/100g) |

Mg (mg/kg) |

P(mg/kg) |

|

A100:0:0 |

2.50a+_0.001 |

2.25a+_0.57 |

0.112e+_0.01 |

0.033c+_0.001 |

|

B90:10:0 |

3.36a.15+_0.031 |

2.28a+_0.35 |

0.112e+_0.01 |

0.049b+_0.005 |

|

C80:10:10 |

3.70a+_0.065 |

2.29a+_0.56 |

0.202d+_0.04 0.306c+_0.008 |

0.059b+_0.005 |

|

D70:10:20 |

4.02a+_0.101 |

2.33a+_0.59 |

0.413b+_0.017 |

0.081a+_0.006 |

|

E60:10:30 |

4.25a+_0.10 |

2.33a+_1.05 |

0.554a+_0.005 |

0.092a+_0.004 |

|

LSD |

0.18 |

1.71 |

0.02 |

0.01 |

Table 4: Micronutrient Composition of composite cookies.

Values are mean+_ standard deviation of three replications. Means with different superscript within the same column are significantly different at (p>0.05 Where PF= Plantain flour, SS= sesame seed ,GNF=groundnut flour

Physical characteristics of cookies

The result of the physical characteristics of cookies produced from unripe plantain, groundnut flour and sesame seeds are presented in Table 5. The result showed that there was significant difference (P<0.05) in weight, diameter and spread ratio between cookies made from 100% plantain flour and composite flours. The weight ratio of the cookies ranged from 14.40g to 18.70g, the diameter ranged from 4.74g to 6.00 and spread ratio ranged from (3.76 to 5.21). There was no significant difference in the thickness as the values ranged from (1.13mm - 1.27mm), with 100:0:0 blended cookies having the highest thickness value of (1.27mm) while 70:10:20 and 60:10:30 blends have the least (1.13) thickness respectively. It was noticed that the diameter of the composite cookies increases with 80:10:10 (6.00mm) having the highest diameter and the lowest 100:0:0 with a diameter of 4.74mm. Addition of sesame seed and groundnut flour to plantain flour increased the diameter, spread ratio and weight of composite cookies. Cookie spread ratio stand for a ratio of diameter to thickness. Cookies with higher spread ratios are considered most desirable [24-40]. Results showed that the spread ratio of composite cookies displayed trend along with an increase in the sesame seed.

|

Sample PF:GF:SS |

Diameter |

Thickness |

Weight |

Spread ratio |

|

A100:0:0 |

4.74b+_0.51 |

1.27a+_0.06 |

18.70a+_0.44 |

3.76b+_0.52 |

|

B90:10:0 |

5.87a+_0.12 |

1.17a+_0.06 |

17.47a+_0.64 |

5.04a+_0.36 |

|

C80:10:10 |

6.00a+_0.10 |

1.20a+_0.10 |

18.10a+_0.66 |

5.02a+_0.46 |

|

D70:10:20 |

5.83a+_0.06 |

1.13a+_0.06 |

14.40b+_1.05 |

5.15a+_0.28 |

|

E60:10:30 |

5.90a+_0.10 |

1.13a+_0.06 |

15.63b+_0.49 |

5.21a+_0.19 |

|

LSD |

0.44 |

0..13 |

1.25 |

0.69 |

Table 5: Physical characteristic of cookies.

Values are mean+_ standard deviation of three replications. Means with different superscript within the same column are significantly different at (p>0.05. Where PF= Plantain flour, SS= sesame seed, GNF=groundnut flour

Sensory analysis of cookies

The sensory properties of cookies prepared from plantain, groundnut flour and sesame seeds are shown in Table 6. There was no significant (p>0.05) difference in taste, texture and overall acceptability of cookies prepared from 100% plantain flour when compared with the composite cookies [40-45]. This result implies that the evaluated sensory properties of 100% plantain cookies are not different from the developed cookies. Cookies prepared with sesame seed, plantain and groundnut flour blends had high acceptability than cookies made from 100% unripe plantain flour. Though the texture of the cookies were good and from the acceptability scores, it was concluded that groundnut flour and sesame flour could be incorporated up to 60:10:30 ratios in the preparation of cookies without much effects [46-50].

|

Sample PF:GF:SS |

Appearance |

Aroma |

Texture |

Taste |

General acceptability |

|

A100:0:0 |

7.13ab |

7.53ac |

7.67a |

7.47a |

7.60a |

|

B90:10:0 |

7.60a |

6.67ab |

7.00a |

7.13a |

7.53a |

|

C80:10:10 |

7.33ab |

6.67ab |

7.47a |

7.00a |

7.53a |

|

D70:10:20 |

6.53b |

6.27b |

7.20a |

6.93a |

7.33a |

|

E60:10:30 |

6.93ab |

6.60ab |

7.07a |

7.13a |

7.80a |

|

LSD |

0.83 |

1.09 |

1.02 |

0.78 |

0.67 |

Table 6: Sensory Analysis of Cookies.

Values are mean+_ standard deviation of two replications

Means with different superscript within the same column are significantly different at(p>0.05

Where PF= Plantain flour, SS= sesame seed, GNF=groundnut flour

Conclusion

This research study indicates that composite cookies is possible from plantain sesame and ground nut flours. It was revealed that groundnut flour and sesame seeds had good functional attributes and thereby can be incorporated as ingredients for cookies production. The addition of groundnut flour and sesame seed increased the quality of the cookies. But the groundnut flour and sesame seed inclusion decrease the weight and thickness of cookies while spread ratio and diameter were increased. The sensory attribute of the cookies from this study was generally improved.

References

- (2003) Diet nutrition and the prevention of chronic diseases. 916: 1-149.

- Hurs H, Martin J (2005) Low-carbohydrate and beyond: The health benefits of inulin. Cereal Food World 50: 57-60.

- Okaka JC (2009) Handling Storage and Processing of Plant Foods.

- Chinma CE, Gernah DI (2007) Physicochemical and sensory properties of cookies produced from cassava soyabean mango composite flours. Journal of Raw Material Resource 4: 32-43.

- Ajanaku KO, Dawodu FA, Ajanaku CO, Nwinyi OC (2011) Functional and nutritional properties of spent grain enhanced cookies. American Journal of Food Technology 6: 763-771.

- Nasir M, Siddiq M, Ravi R, Harte JB, Dolan KD, et al. (2005) Health properties of resistant starch. Nutr Bull 30: 27-54.

- Onoja US, Obizoba IC, Ezeji JI (2010) Physico-chemical energy, minerals, vitaminsand sensory properties of wheat based biscuit supplemented with African yam-bean,cowpea, pigeon pea, water yam, cocoyam and plantain flour. Nigerian Journal of Nurtritional Science 31: 62-67.

- Gernah DI, Akogwu AM, Sengev AI (2010) Quality evaluation of cookies produced from composite blends of wheat flour and African locust bean fruit pulp flour. Nigerian Journal of Nutritional Science 31: 20-24.

- Arshad MU, Anjum FM, Zahoor T (2007) Nutritional assessment of cookies supplemented with defatted wheat germ. Food Chemistry 102: 123-128.

- Giami SY, Achinewhu SC, Ibaakee C (2005) The quality and sensory attributes of cookies supplemented with fluted pumpkin seed flour. International Journal of Food Science and Technology 40: 613-620.

- Shrestha AK, Noomhorm A (2002) Comparison of physico-chemical properties of biscuits supplemented with soy and kinema flours. International Journal of Food Science Technology 37: 361-368.

- Akubor PI, Ukwuru MU (2003) Functional properties and biscuit making potential of soybean and cassava flour blends. Plant Foods Human Nutrition 58: 1-12.

- Narayana K, Narasinga-Rao MI (1982) Functional properties of raw and heat processed winged bean Psophocarpus tetragonolobus flour. Journal of food science 42: 1534-1544.

- Akpata MI, Akubor PI (1999) Chemical composition and selected functional properties of sweet orange (citrus sinensis) Seed Flour. Plant Food Human Nutrition 54: 353-362

- Wade and Stafford (1968) The chemical analysis of food. 74 Edition. Churchchill Live store 205-206.

- Okpala LC, Chinyelu VA (2011) Physiochemical, Nutritional and Organaleptic Evaluation of Cookies from Pigeo pea (Cajanus cajain) and cocoyam (xanthosoma sp) flour blends. American Journal of Food and Nutrition 11: 5431-5443.

- Elleuch M, Bedigian D, Roiseux O, Besbes S, Blecker C (2011) Dietry fibre and fibre-rich by-products of food processing: Characterisation, technological functionality and commercial applications. Review on Food Chemistry 124: 411-421.

- Owiredu L, Laryea D, Barimah J (2013) Evaluation of cashew nut flour in the production of biscuit. Nutrition and Food Science 44: 204-211.

- Mcwillien M (1978) Food foundamental 3d edition. California State University Los Angeles 27-29.

- Messiaen CM (1992) The tropical vegetable garden maemillian Ltd. London and Basing Stoke. 218-247.

- Giwa EO, Abiodun IV (2010) Quality characteristics of biscuits produced from composite flours os wheat and quality protein maize. African Journal of Food Science 1: 116-119.

- Ayo JA, Ayo VA, Nkama I, Adewori R (2007) Physiochemical, invitro digestibility and organoleptic evaluation of acha-wheat biscuit supplemented with soybean flour. Nigerian Food Journal 25: 15-17.

- Srivastava S, Genitha TR, Yadav V (2012) Preparation and Quality Evaluation of Flour and Biscuit from Sweet Potato. Journal of Food Processing Technology 3: 3-5.

- Gharbia HA, Shahidi F, Shahata AAY, Youssef MM (1997) Effects of processing on oxidative stability of sesame oil extracted from intact and dehulled seeds. Journal of American Oil Chemist Society 74: 215-221.

- Agriga AN, Iwe MO (2009) Proximate composition of cookies produced from cassava groundnut-corn starch blend. Nigerian Food Journal 27: 102-107.

- Ayodele OH, Erema VG (2011) Glycemic indices of processed unripe plantain meals. African Journal of Food Science 4: 514-521.

- Bandyopadhyay K, Ghosh S (2002) Preparation and characterization of papain modifiedsesame (Sesamum indicum L.) protein isolates. Agricultural Food Chemistry 50: 6854-6857.

- Benigo EB, Mepha HD (2005) Certain functional properties of wheat breadfruit composite flours. In proced. 29th Annual Conference of Nigerian Institute of Food Science and Tech. (NIFST) Enugu, Nigeria P: 49b-49.

- Banting AH, Gibbons RW, Wynne JC (1985) Groundnut (Arachis hypogaea L.) In Grain Legume Crops. R.J. Summerfield and E.H. Roberts, eds. London: Collins 747-800.

- Butt (2010) Physical quality characteristics and sensory evaluation of cookies made with addeddefatted maize germ flour. J of Food Qualit 33: 72-84.

- Chinma CE, Igbabul BD, Omotayo OO (2012) Quality Characteristics of Cookies Prepared from Unripe Plantain and Defatted Sesame Flour Blend. American J of Food Tech 7: 398-408.

- Coffelt TA (1989) Peanut. In Oil Crops of the World: Their Breeding and Utilization El-Adawy, TA (1997) Effect of sesame seed protein supplementation on the nutritional, physical, chemical and sensory properties of wheat flour bread. Food Chemistry 59: 7-14.

- Hammons RO (1982) Origin and Early History of the Peanut. In Peanut Science and Technology. H.E. Pattee and C.T. Young eds. Yoakum, Tex. American peanut Research and Education Society Inc 1-20.

- Hui YH (1996) Edible Oil and Fat Products: General Applications. John Wiley and Sons, Inc,USA.

- Sideani A, Jideani VA (2011) Developments on the cereal grains Digitaria exilis (acha) and Digitaria iburua (iburu). J of Food Sci and Tech 48: 251-259.

- Amaljit K, Baljeet S, Amarjeet K (2010) Preparation of bakery products by incorporating pea flour as a functional ingredient. American J of Food Tech 5: 130-135.

- Kaushal P, Kumar V, Sarma HK (2012) Comparative study of physic-chemical, functional, anti-nutritional and pasting properties of taro (colocasia esculenta), rice (Oryza sativa), pigion pea (cajanus cajan) flour and their blends. LWT-Food Sci and Tech 48: 59-68.

- MeWatters KH, Ouedraogo JB, Resurreccion AV, Hung YC, Phillips RD, et al. (2003) Physical and sensory characteristics of sugar cookies containing mixtures of wheat, fonio (Digitaria exilis) and cowpea (Vigna unguiculata) flours. Int J of Food Sci and Tech 38: 403-410.

- Ndife J, Kida F, Fagbemi S (2014) Production and quality assessment of enriched cookies from whole wheat and full fat soya. Eu J of Food Sci and Tech 2: 19-29.

- Nwoji VC (2004) Effect of processing on the storage stability and functional properties of cowpea (vigna unguculata) flour in the production of cowpea bean (akara) and paste (moin-moin). In proced. 29th Annual Conference of Nigerian Institute of Food Science and Tech. (NIFST) Enugu, Nigeria 199.

- Nwokolo E (1996) Peanut (Arachis hypogaea L.). In Food and Feed from Legumes and Oilseeds. E. Nwokolo and J Smart eds New York: Chapman and Hall 49-63.

- Okpala LC, Okoli EC (2011) Nutritional evaluation of cookies produced from pigeonpea, cocoyam and sorghum flour blends. African Journal of Biotechnology 10: 433-438.

- Osundahunsi OF, Awor OC (2002) A preliminary study on the use of Tempe-Based formula as a weaning diet in Nigeria. Plant Foods for Human Nutrition 57: 365-376.

- Rehinan Z, Rashid M, Shah WH (2004) Insoluble dietary fibre components of food legumes as affected by soaking and cooking processes. Food Chemistry 85: 245-249.

- Shrestha AK, Noomhorm A (2002) Comparison of physico-chemical properties of biscuits supplemented with soy and kinema flours. International Journal of Food Science Technology 37: 361-368.

- Singh J, Singh N, Sharma TR, Saxena SK (2003) Physicochemical theological and cookie making properties of corn and potato flours. Food Chemistry 83: 387-393.

- Singh S, Ria CS, Saxena DC (2008) Effect of incorporating sweet potato flour to wheat flour on the quality characteristics of cookies. African Journal of Food Science 2: 65-67.

- Tilman JC, Colm MOB, Denise MC, Anja D, Elike KA (2003) Intluence of gluten free flour mixes and fat powder on the quality of gluten free biscuits. Journal of European Food Research Technology 216: 369-376.

- Wang JC, Kinsella JE (1976) Functional properties of novel protein: Alfalfa leaf protein. Journal of Food Science 41: 286-292.

- Wardlaw GM (2004) Perspective in Nutrition 6h (Edn)-MGram Hill Companies. New York, USA.

Citation: Ogori AF, Amove J, Okponya OJ (2022) Physiochemical Properties of Composite Cookies Made from Un-Rip Plantain, Groundnut Flour and Sesame Seeds Influenced by Blend Variation. J Food Sci Nutr 8: 147.

Copyright: © 2022 Ogori AF, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.