Process Standardization and Characterization of Mozzarella Cheeses Prepared Using Dry Plasticizing Techniques

*Corresponding Author(s):

Jana AtanuDepartment Of Dairy Processing & Operations, SMC College Of Dairy Science, Anand Agricultural University, Anand, Gujarat, India

Email:Indiaatanujn@gmail.com

Abstract

Plasticizing of Mozzarella cheese curd using hot water (i.e., wet method) involves considerable losses of milk solids leading to reduction in cheese yield and economical loss. Research was carried out to standardize Mozzarella cheese making employing two methods of ‘dry plasticizing’ of cheese curd viz., (A) Induction Heating (IH), and (B) Convective Heating (CH). In case of IH, the cheese curd was heated using induction mode at power level of 100W keeping contact period of 7.0 min. In case of CH, the cheese curd was heated in oven utilizing convective heating at temperature of 230°C keeping contact period of 15.0 min. Control Mozzarella cheese curd was plasticized in hot (85°C) water keeping contact period of 3.0 min. Emulsifying salt blend comprising of Trisodium Citrate (TSC) and Disodium Phosphate (DSP) (i.e., TSC:DSP of 3:1, w/w of curd) was required to control fat destabilization when using dry plasticizing methods; the optimal usage level was 0.60 % w/w by cheese curd. The cheeses prepared using dry plasticizing and wet plasticizing methods had composition that conformed to FSSA standard for Pizza cheese. Cheeses made using dry plasticizing method exhibited superior recovery of milk solids, had enhanced cheese yield and exhibited highly satisfactory baking properties. Use of IH for dry plasticizing of Mozzarella cheese curd is recommended to reap the benefits of cheese yield and baking functionality.

Keywords

Convective heating; Emulsifying salt; Induction heating; Mozzarella cheese, Plasticizing methods

INTRODUCTION

Mozzarella cheese (specifically Pizza cheese variant i.e. low-moisture part-skim Mozzarella) is the preferred topping for pizza pie. Traditionally, Mozzarella cheese was produced employing ‘starter culture’ method. However, ‘direct acidification’ technique has gained considerable commercial interest as it aids mechanization of production and the cheese making does not encounter any problems emerging from the presence of bacteriophage or antibiotics [1].

Plasticizing of cheese curd is an important step in the manufacture of Mozzarella cheese. Plasticizing of curd affects the cheese composition which directly influences the properties of cheese by controlling the microbial activity, enzyme activity, texture and even baking characteristics [2]. The conventional method of curd plasticizing involves use of hot water (80-85oC), enabling the cheese curd to stretch. However, such process involves considerable losses of milk solids adversely affecting the cheese yield; it also produces effluent. Any change in any processing step of cheese making (i.e., plasticizing of cheese curd) is bound to affect the yield, composition, as well as the baking characteristics of resultant Mozzarella cheese [3]. The influence of dry plasticizing of cheese curd on the quality characteristics of Mozzarella cheese is lacking in literature.

Now-a-days, steam stretching machines housed with dipping arms are the emerging equipment for stretching of cheese curd [4]. In recent years, direct steam technology is gaining momentum due to improved texture of the finished product and better control of cheese composition. In this method, the curd comes directly in contact with steam in a closed chamber and avoids discharge of any fatty water that forms during kneading and working process [5]. Hence, the present investigation attempts to study the effect of ‘dry plasticizing’ (without using hot water) techniques to obtain Mozzarella cheese with attendant benefits and compare them with cheese prepared using ‘wet plasticizing’ (using hot water) method with regard to the composition, recovery of milk constituents in cheese, yield and baking characteristics of cheese.

MATERIALS AND METHODS

Raw materials

Fresh, raw mixed (cow and buffalo) whole milk was procured from Vidya Dairy, Anand (Gujarat, India). The freshly separated skim milk was used to standardize the cheese milk. Rennet (Fromase 106 TL derived from Mucor miehei, strength of 1/106000 units) was obtained from an Indian firm representing M/s. Gist-Brocades, Delf, Holland. Lactic acid and Calcium chloride, dihydrate were procured from M/s. Loba Chemie Pvt. Ltd., Mumbai. Tata brand vacuum-evaporated common salt (NaCl) was used for salting of cheese. Tri-sodium citrate, dihydrate (M/s. Loba Chemie Pvt. Ltd., Mumbai), and di-sodium hydrogen orthophosphate, anhydrous (M/s. Central Drug House Pvt. Ltd., New Delhi) were used as emulsifying salts.

Equipment

Baking oven (Kenstar - 3D Power, Model-OM-34ECR) was used for heating the cheese curd to plasticize the same. Induction cook-top (M/s. TTK Prestige Ltd., Hosur, India; Model PIC 2.0 V2® 2000 Watt power, operating at 230 V AC, 50 Hz.) was also used to plasticize the cheese curd. Muffle furnace (model No. EIE- 500, Erection and Instrumentation Engineers, Ahmedabad) of 5 kW power was used for ashing the cheese.

Cheese making

Raw mixed milk was standardized to 3.0% milk fat for preparation of Mozzarella cheese by direct acidification method using lactic acid (20.0% w/v solution), following the method standardized by Patel GC, et al. [6]. The plasticizing step of cheese curd was modified as per the protocol of the present investigation.

The two alternative plasticizing techniques (referred to as ‘dry plasticizing methods’) employed in the manufacture of Mozzarella cheese were (a) induction heating (T1), and (b) convection heating (T2). The control Mozzarella cheese (C) was prepared using hot water (85oC/3-5 min. contact period; curd: moulding water 1.0:2.5, w/v) for plasticizing (i.e. wet plasticizing).Common salt (NaCl) was used @ 1.0 % by weight of cheese curd in case of dry plasticizing (i.e. T1, T2), while control cheese curd was salted @ 2.5 % by weight. The drained cheese curd, post cooking step, having the desired pH (5.2-5.6) was subjected to ‘stretch’ test and then plasticized.

Convection heating

Dry salted cheese curd (500.0 g in one lot) placed in a thermo-resistant glass bowl (Borosil make) was kept in a pre-heated (180°C, 210°C, 230°C) convection oven for requisite period for the cheese curd to get plasticized.

Induction heating

Dry salted cheese curd (500.0 g in one lot) collected in a non-stick metal pan (Prestige Co.) was placed on the induction cook top, setting the machine at 100, 300 and 600 W power and kept for requisite period enabling the cheese curd to get plasticized.

Yield of cheese

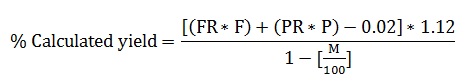

The yield of Mozzarella cheese was expressed as kg cheese obtained from 100.0 kg of standardized cheese milk. The calculated yield of cheese was derived as follows:

Where, FR and PR = fat and protein recoveries in cheese respectively; F and P = fat (%) and protein (%) in milk respectively; M = moisture (%) in cheese.

Analyses

The standardized cheese milk was analyzed for fat, protein and Total Solids (TS).The fat content of milk was determined using Gerber method [7]. Total nitrogen of cheese milk was determined using semi-micro Kjeldahl method [8], using Kel-Vac digestion system and Kjel-Plus semi-automatic distillation system; both of M/s. Pelican Instruments, Chennai, India.

Mozzarella cheese was analyzed for moisture, fat, protein, salt, ash and pH. The TS of cheese was determined using Mojonnier Milk Tester, Model-D [9]. The fat content of cheese was determined following the method of Van Gulik [10]. The ash and salt (sodium chloride) content of cheese was determined using standard method [10,11]. The protein content of cheese was determined using semi-micro Kjeldahl method [8] substituting milk with cheese. The pH readings of cheese slurry prepared in distilled water were taken on digital pH meter (M/s. Mettler Toledo AG, Schwerzenbach).

Baking characteristics of cheese

The shredability was assessed subjectively during manual shredding of cheese through a stainless steel shredder (pore size 2.0 mm diameter). The meltability of cheese samples was determined by ‘Schreiber test’ [12] while the fat leakage of cheese was determined by the method of Breene et al. [13]. Stretch test of cheese was performed using ‘Fork test’ [14] using four pronged fork.

RESULTS AND DISCUSSION

Process standardization for Mozzarella cheese

The plasticizing step of cheese curd was modified as per the protocol of the present investigation. The parameters studied were: (a) optimizing the power level of induction cooker and the contact period of cheese curd for plasticizing, (b) optimizing the temperature of convection oven and the contact period of cheese curd for plasticizing, and (c) optimizing the rate of addition of emulsifying salt to the cheese curd.

Optimizing induction heating for cheese curd plasticizing

Induction heating is quite a recent introduction and has been adopted very popularly for domestic usage and in small scale factories. Since the mode of heating the food product using induction heating is not the same as is the case with traditional methods (i.e., heating of cheese curd using hot water or steam), a need was felt to evaluate the quality of cheese that had been subjected to heating by such alternative mode. Nowadays, induction heaters for cooking applications are gaining momentum owing to convenience (space) and complete avoidance of fire (safety aspect). The heat is generated in induction cooker due to the eddy currents generated in the pot’s bottom layer combined with the hysteresis losses from the magnetic material in the pan [15]. Induction cooking technology offers better efficiency conversion compared to the conventional heating (gas and electric stoves), facilitates rapid heating, direct heating, high power density, low running cost and non-acoustic noise [16].

As per Food Safety and Standards Act [17] ‘Pizza cheese’ (a variant of Mozzarella cheese) should possess a minimum of 35.0 % fat on dry matter (FDM). Use of induction or convective heating for plasticizing the cheese curd led to surface oiling-off during moulding of the cheese mass. Hence, it was necessary to use emulsifying salt to aid in emulsification of milk fat in the cheese mass, treated using dry plasticizing methods

It was necessary to control the power level of induction cooker and determine the required contact period of the cheese curd with the cooker, so that curd plasticization is feasible. Dry salted cheese curd (0.5 kg in one lot) contained in a non-stick metal pan was taken for plasticizing. The power levels used for induction heating were 100 W, 300 W and 600 W.

Increasing the power level of induction cooker from 100 to 600 W led to reduction in the contact period required for the cheese curd to get plasticized. Use of higher power levels (i.e. 300, 600W) adversely affected the quality of resultant cheese (Table 1). The contact period required for plasticizing the cheese curd when using induction heating was 2.0-2.5 min., 3.5-4.5 min. and 6.5-7.0 min respectively when power level was set at 600 W, 300 W and 100 W respectively.

|

Power level (W) of induction cooker |

Contact period (min.) |

Quality of cheese curd |

|

100 |

6.5-7.0 |

Firm curd, less free fat aiding in achieving FDM content of cheese above the minimum (i.e. 35.0 %) specified by FSSA. Cheese was amenable to baking operation. |

|

300 |

3.5-4.5 |

Too greasy curd; cheese unable to meet the FDM requirement specified by FSSA. The cheese did not perform satisfactorily during baking application. |

|

600 |

2.0-2.5 |

Excessive oozing of free fat from cheese body. Cheese did not satisfy the FDM requirement specified by FSSA. Cheese had corky body and showed presence of scorched particles. |

Table 1: Quality characteristics of cheese curd plasticized using induction heating with varying power levels

FDM = Fat-on-dry matter; FSSA = Food Safety and Standards Act.

The Mozzarella cheese could satisfy the FDM content prescribed by FSSA [17] only when the power level kept was minimum (i.e. 100 W); the cheese obtained in this manner was moderately firm and exhibited good shredding property.

Based on the above findings, it was decided to employ plasticizing condition: 100 W power level in induction cooker keeping contact period of 7.0 min. with the cheese curd, for a batch size of 500.0 g.

Optimizing convective heating for cheese curd plasticizing

Literature exists in relation to standardizing the processing parameters to plasticize Mozzarella cheese curd adequately utilizing hot water [2] or even steam (direct or indirect, usually indirect heating) [4,5]. However, no attempt has been made so far in plasticizing cheese curd using convective oven. Hence, a need was felt to optimize the parameters required to successfully plasticize Mozzarella cheese curd using convective heating. The convection heating in oven is widely practiced in commercial processing as well as in domestic cooking [18]. Unlike conventional radiant ovens, convection ovens have provision of a fan that continuously circulates air through the oven cavity, making cooking rapid. Dry salted cheese curd (0.5 kg in one lot) at desired pH (i.e., about 5.4) contained in a thermo-resistant glass bowl was kept in the preheated oven, so that the cheese curd was amenable to plasticizing.

The temperature of convection oven was set at 180, 210 and 230°C for heating the cheese curd, ready for plasticizing. There was an inverse relation between heating temperature of the oven and the time required for plasticizing the cheese curd. The contact period necessary for the cheese curd to be plasticized was 25.0-28.0 min., 17.0-18.0 min. and 14.0-15.0 min. respectively when oven temperature was maintained at 180°C, 210°C and 230°C.

Unlike the conditions of induction heating (especially power levels), the rise in the temperature of convective heating did not have much adverse effect on the quality characteristics of the resultant cheese. The cheese mass subjected to heating in convective oven could satisfy the requirement for FDM laid down by FSSA and the cheese mass exhibited desired curd stretching properties when the temperature of oven was kept at higher side (i.e. 210°C or 230°C). Based on the quality of cheese mass and considering the fat losses, convection oven temperature of 230oC (15.0 min. contact period) was selected for plasticizing the cheese curd (Table 2).

|

Temperature of convection oven |

Period of contact (min.) |

Quality of cheese curd |

|

180°C |

25-28 |

Cheese body exuded free fat. Ball formation (i.e. moulding) was hindered and cheese had corky body. Time required to plasticize the cheese was longer. Cheese did not comply with FDM content specified by FSSA for Mozzarella cheese. Cheese did not perform well during baking. |

|

210°C |

17-18 |

Improvement in ball formation during moulding step was noticed. Firm curd produced. Lower free fat enabled the cheese to satisfy FDM content specified by FSSA. Cheese baking property was slightly improved. |

|

230°C |

14-15 |

Firm curd produced. Reduced free fat enabled meeting the minimum FDM level specified by FSSA for Mozzarella cheese. Time required to plasticize the cheese mass was minimum (i.e., 14.0 min.). Cheese was amenable to baking operation. |

Table 2: Quality characteristics of cheese curd plasticized using convective heating at varying temperatures. FDM = Fat-on-dry matter; FSSA = Food Safety and Standards Act.

Optimizing the rate of addition of emulsifying salt

Mozzarella cheese making by traditional method does not require use of Emulsifying Salts (ES). In processed cheese making and in processed Mozzarella cheese making[19], use of ES is indispensable. In the present investigation, when employing inductive or convective mode of heating to plasticize the cheese curd, there was a problem of fat de-emulsification in the resultant cheese. This problem required to be tackled and based on the principle of action of ES in processed cheese system [20], it was contemplated to use such food additive to tide over the difficulty faced. ES is known to act on protein and thereby affect the emulsification of fat in processed cheese [20,21] and similar cheese systems. ES have the ability to solubilize and hydrate protein during processing of cheese [22]. The role played by ES in improving the meltability of cheese has been established [20,23].

In the initial trials, ES such as Trisodium Citrate (TSC) and mixture of TSC and Disodium Hydrogen Orthophosphate (DSP) were incorporated in cheese curd, prior to plasticizing. The mixture of TSC and DSP (3:1, w/w) when used at levels of 0.6 to 1.0 % by weight of cheese curd improved the state of emulsification of milk fat in plasticized Mozzarella cheese and the resultant cheese had desired baking qualities (viz., fat leakage, stretch, melt). When TSC was used alone as ES at similar rate of addition, the emulsification of milk fat was inferior; the cheese mass exhibited some visible free fat on its surface during its moulding in ball shape.

When the ES blend (TSC and DSP; 3:1 w/w) was incorporated in Mozzarella cheese mass prior to plasticizing operation, the product had desired fat content (21.5-23.5 % fat) satisfying the FSSA requirement for FDM. When ES was omitted in cheese making, the fat content (i.e. 15.5-16.5 % fat) could not satisfy the FSSA requirements for Mozzarella cheese.

The quality of cheese curd at the time of plasticizing is described in Table 3, based on which a level of 0.6 % of ES blend was finally selected (Table 3).

|

Level of emulsifying salt* (%, w/w of cheese curd) |

Quality of cheese curd |

|

0.6 |

Firm cheese curd obtained with minimal free fat. Mozzarella cheese satisfied FDM content specified by FSSA. Cheese was amenable to baking. |

|

0.8 |

Slightly reduced firmness of cheese curd with minimal free fat. More or less similar properties as obtained when using 0.6 per cent ES. |

|

1.0 |

Softer cheese curd obtained with minimal free fat. Slight adverse effect on stretch property of cheese was noted. |

Table 3: Effect of level of emulsifying salt(s) on the quality characteristics of plasticized cheese.

*Emulsifying salt was a blend of TSC and DSP (3:1, w/w).

The use of ES (viz., DSP, TSC) in process cheese manufacture is reported to improve the emulsifying properties of casein by displacing the calcium phosphate complexes in the insoluble calcium-paracaseinate phosphate network present in natural cheese [24,25]. Such displacement disrupted the molecular force, cross?linking the various monomers of casein in the network. Such phenomena in conjunction with heating and mixing led to hydration and partial dispersion of the Calcium-Paracaseinate Phosphate (CPP) network. In addition to being hydrated, the partially dispersed CPP complex interacted with fat through hydrophobic interactions. During the cooling stage of cheese, the partially dispersed caseinate matrix formed ‘flocs’, resulting in a uniform, closely-knit gel structure [26]. Such close knit gel network keeps the milk fat in the emulsified state [26,27].

The use of ES is one of the effective ways to enhance cheese functionality. Luo et al., [28] investigated the effects of two types of ES [TSC and trisodium pyrophosphate (TSPP)] on the functionality of Mozzarella cheese. TSC and TSPP were added to the moulding water at level of 1.0 to 5.0 % during plasticizing step. There was an improvement in the hardness and cohesiveness of cheese, but the cheese exuded greater free oil content when the level of ES was raised. Incorporation of such ES blend markedly improved the meltability of Mozzarella cheese. The mechanism of improvement in meltability of cheese was ascribed to the improved solubilization of phosphate in the cheese, resulting in decreased protein-protein interaction and increased protein-water interaction.

In literature, an alternative method for stretching of Mozzarella cheese curd involved addition of 1.0-1.5 % of ES blend (i.e. TSC and DSP; 1:1 or 2:1 w/w) to the cheese curd, heating such cheese mass to 65-70°C for 10-15 min., followed by moulding into desired shape. Such cheese had improved melting characteristics, flavour and texture as compared to control cheese made by conventional stretching of cheese curd in hot water [23].

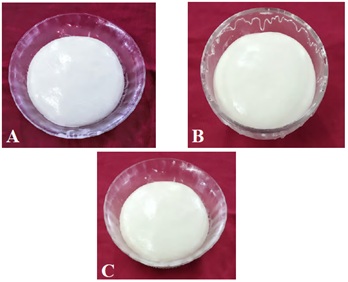

Based on the experiment carried out in standardizing the processing parameters for Mozzarella cheese making employing ‘dry plasticizing technique’, the optimized conditions arrived at is collated in Table 4. The photographs of Mozzarella cheeses produced using two ‘dry plasticizing’ methods and ‘wet plasticizing’ method is shown in Figure 1.

|

Parameters |

Conditions for plasticizing 500.0 g of cheese curd |

|

Induction heating |

Power level of 100 W with contact period of 7.0 min. |

|

Convection heating |

Oven temperature of 230°C with contact period of 15.0 min. |

|

Type and level of emulsifying salt(s) |

TSC and DSP (3:1, w/w) at level of 0.6% by weight of cheese curd |

Table 4: Optimized conditions for dry plasticizing of Mozzarella cheese curd.

TSC = Trisodium Citrate, DSP = Disodium Phosphate

Figure 1: Mozzarella cheese plasticized using (A) Induction heating, (B) Convective heating and (C) Hot water.

Figure 1: Mozzarella cheese plasticized using (A) Induction heating, (B) Convective heating and (C) Hot water.

Yield of mozzarella cheeses

Cheese yield is defined as the amount (kg) of cheese obtained from 100 kg of milk. The cheese yield (Table 5) has been expressed per cent yield as well as the yield based on calculation using the formula suggested by Olson et al., [29]. Monitoring the cheese yield in a cheese factory gives a notion about the efficiency of cheese making operations [30]. Increase in the yield of cheese can result in greater net returns to the cheese maker.

|

Parameters |

Yield of Mozzarella cheeses plasticized using treatment |

||

|

T1 |

T2 |

C |

|

|

Actual yield, % |

12.90±0.33a |

13.03±0.33a |

10.95±0.28b |

|

Calculated# yield, % |

13.11±0.32a |

13.27±0.33a |

11.31±0.30b |

Table 5: Yield of Mozzarella cheese as affected by plasticizing treatments

T1, T2, C = Cheese curd plasticized using Induction heating, Convection heating and Hot water respectively; # = calculation as per Olson et al. [29]; differing superscripted alphabets in the same row indicates significantly different (P<0.05)

Both the actual as well as calculated yield of Mozzarella cheeses T1 and T2 were significantly (P<0.05) greater than that of control cheese (C). However, the actual as well as calculated yield of the former two cheeses (i.e., T1, T2) was at par with each other (Table 5). The actual yield of cheeses T1 and T2 was greater than the yield of control cheese by 17.80 and 18.99% respectively. Surprisingly, even though the cheeses prepared using dry plasticizing methods (T1, T2) (vs. C) were associated with significantly (P<0.05) lower moisture content, they were associated with markedly higher cheese yield. Such findings might be ascribed to the marked increase in the recovery of milk constituents recorded in such cheeses (T1, T2) (Table 6).

|

Milk constituents |

Recovery of milk constituents in Mozzarella cheeses prepared using plasticizing treatments |

||

|

T1 |

T2 |

C |

|

|

Fat |

94.71±3.36a |

94.60±3.66a |

79.12±1.31b |

|

Protein |

97.75±1.53a |

97.15±1.74a |

78.05±2.10b |

|

Total Solids |

60.48±2.56a |

60.60±3.78a |

47.02±2.34b |

Table 6: Recovery of milk solids in Mozzarella cheese as affected by plasticizing treatments.

T1, T2, C = Cheese prepared by plasticizing using Induction heating, Convection heating and Hot water respectively; differing superscripted alphabets in the same row indicates significantly different (P<0.05).

The yield of Mozzarella cheese prepared using (i) microwave heating (40°C, 5.0 min.) and (ii) hot moulding water (80°C, 3.0 min.) was 10.5 % and 10.0 % respectively [31]. The yield of Mozzarella cheese prepared from cow and buffalo milk is reported to range from 9.93 to 11.69, and 10.50 to 14.16 % respectively [32-35].

Proximate composition of Mozzarella cheeses

The composition of standardized cheese milk dictates the composition of the resultant Mozzarella cheese; the losses of milk solids in whey and molding water also influences the cheese composition. The proximate composition of Mozzarella cheeses prepared using three plasticizing techniques (two experimental, one control) is presented in Table 7.

|

Constituents (%) |

Composition of Mozzarella cheeses plasticized using treatment |

||

|

T1 |

T2 |

C |

|

|

Moisture |

45.82±0.63a |

47.05±0.66b |

51.89±0.74c |

|

Fat |

23.29±0.37a |

22.65±0.28b |

20.90±0.51c |

|

Fat on dry matter |

42.98±0.19a |

42.78±0.02a |

43.45±0.51b |

|

Protein at constant (48.0 %) moisture |

25.00±0.11a |

25.19±0.08a |

25.30±0.20a |

|

Salt |

0.92±0.01a |

0.95±0.03a |

0.96±0.04a |

|

Ash |

2.85±0.06a |

2.74±0.08a |

2.07±0.13b |

|

pH |

5.34±0.05a |

5.35±0.04a |

5.38±0.02a |

Table 7: Proximate composition of Mozzarella cheese as affected by plasticizing treatments.

T1, T2, C = Cheeses prepared by plasticizing using Induction heating, Convection heating and hot water treatment respectively; differing superscripted alphabets in the same row indicates significantly different (P<0.05).

The two experimental (i.e., T1, T2) and one control (i.e., C) Mozzarella cheese conformed to the FSSA requirements for Pizza cheese [17]. The moisture content of cheeses T1 and T2 was significantly (P<0.05) lower than the moisture associated with control cheese. Within ‘dry plasticized’ cheeses, cheese T2 had markedly (P<0.05) higher moisture content than cheese T1. The FDM content of control cheese was highest; such value differed significantly (P<0.05) from the values associated with other two cheeses (i.e. T1, T2; Table 7). All the cheeses had protein at constant moisture (PCM) that was at par with each other. The ash content of control cheese (C) was significantly (P<0.05) lower when compared to that of cheeses T1 and T2; the latter two cheeses had similar ash content. Cheese samples T1 and T2 had similar FDM, PCM, ash and salt content (Table 7).

The differing ash and FDM content when comparing control cheese (C) with T1 and T2 might be related to the use of ES in case of the latter two cheeses. The least ash content associated with control cheese (hot water heating) might be due to losses of soluble minerals that might have leached into the moulding water. Incorporation of ES in cheese making aids in better emulsification of milk fat in cheese matrix leading to an increase in the FDM content [36].

The stretch character of Mozzarella cheese is attained at a specific pH (i.e. 5.6-5.7 for cheese prepared by direct acidification). Hence, the pH of cheese was also analyzed. The pH of all the three Mozzarella cheeses was at par with each other (Table 7).

According to Kaushal et al., [31], the moisture (54.72 %) and fat (21.24 %) content of Mozzarella cheese prepared using hot water (80oC, 3 min.) plasticizing was markedly greater as compared to the cheese (51.92 % moisture, 21.05 % fat) plasticized using microwave heating (40oC, 5 min.).The compositional values of control Mozzarella cheese of the present study is in line with the values reported by Fasale et al., [37]. The moisture, fat, protein and ash content of Mozzarella cheese is reported to be 50.30, 20.61, 22.87 and 2.89 % respectively; the pH of cheese was 5.60 [38,39].

Recovery of milk constituents in cheese

The recoveries of milk constituents namely protein and fat in cheese has a direct relation with cheese yield [40]. Use of conventional plasticizing method (hot water at 75-85°C) in the manufacture of Mozzarella cheese leads to losses of milk constituents during draining of the moulding water. If dry plasticizing technique is employed, such losses are avoided.

The cheeses prepared using dry plasticizing techniques (T1,T2) had significantly (P<0.05) greater recovery of each constituent (i.e., fat, protein, TS) as compared to the product prepared using wet plasticizing method (i.e. C) (Table 6). The increase in the recovery of fat for T1 and T2 cheeses over C was 19.70 % and 19.56 % respectively. Likewise, the increase in recovery of protein for T1 and T2 cheeses over C was 25.24 % and 24.47 % respectively. Finally, the increase in recovery of TS for T1 and T2 cheeses over C was 28.62 % and 28.88 % respectively (Table 6). It is interesting to note that the recoveries of fat, protein and TS of cheeses prepared using two dry plasticizing methods (i.e., T1, T2) were superior (vs. C) but were at par with each other.

In case of the two dry plasticizing methods, draining of moulding water is not involved. Hence, the losses of milk constituents tend to be minimal; only the milk solids adhering to the processing kettle and in moulding (ball forming) machines contributes to the miniscule loss.

The average fat, protein and TS recoveries of control Mozzarella cheese of the present investigation were 79.12, 78.05 and 47.02 % respectively. Demott BJ [40], reported the values of fat, protein and TS recoveries of Mozzarella cheese prepared using direct acidification and wet plasticizing method to be 84.31, 67.20 and 47.53 % respectively. Bhattarai et al., [41], reported fat and protein recoveries of Mozzarella cheese to be 81.07 and 77.22 % respectively. The protein and TS recovery of Mozzarella cheese is reported to be 69.03 and 52.01 % respectively [35,42]; wet plasticizing method was practiced.

Baking properties of Mozzarella cheeses

The baking properties of Mozzarella cheese evaluated were shredability, meltability, fat leakage and stretchability.

Shredability

When used for pizza and most other applications, the cheese must first be cut, diced or shredded into discrete particles, to facilitate even melting on pizza. Hence, Shredability and resistance to clumping, post-shredding, are the major determinants of overall functional characteristics of Pizza cheese [43].

The cheese offering minimal resistance during manual shredding and if the shreds formed were thin and long with little tendency to mat, post-shredding, such cheeses were categorized as having ‘Excellent’ shredability. Cheese offering moderate resistance to shredding and if the shreds formed were thick and short and exhibited moderate tendency to mat, post-shredding, such cheeses were categorized as having ‘Good’ shredability. The cheeses behaving in a manner in between the above two categories were termed as ‘Very Good’.

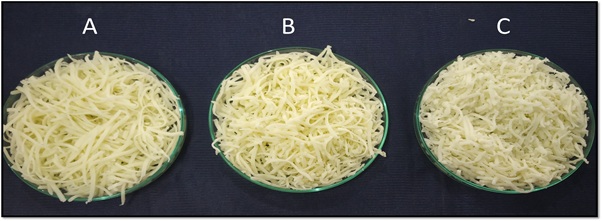

The photographs of shredded Mozzarella cheeses prepared using varying plasticizing techniques are shown in Figure 2. The shred quality of Mozzarella cheese plasticized using induction heating (T1) was rated as ‘excellent’, whereas those made using convection heating (T2) and hot water (C) were rated as ‘very good’ and ‘good’ respectively. The greater protein content (Table 7) and hardness (12.98 N, 10.59 N and 10.87 N for cheese T1, T2 and C respectively; N = Newton force) associated with cheese T1 compared to other two cheeses might have contributed to the superior shredability (Table 8) of former cheese.

Figure 2: Shred quality of Mozzarella cheese plasticized using (A) Induction heating, (B) Convective heating, and (C) Hot water.

Figure 2: Shred quality of Mozzarella cheese plasticized using (A) Induction heating, (B) Convective heating, and (C) Hot water.

|

Baking qualities |

Baking qualities of Mozzarella cheese prepared using treatment |

||

|

T1 |

T2 |

C |

|

|

Shredability |

Excellent |

Very good |

Good |

|

Schreiber meltability (Arbitrary value) |

5.67±0.14a |

5.94±0.25a |

4.72±0.08b |

|

Fat leakage (cm2) |

1.92±0.13a |

2.83±0.23b |

1.35±0.08c |

|

Stretch value (cm) |

33.60±0.97a |

31.50±2.83a |

29.00±0.84b |

Table 8: Mozzarella cheese as influenced by the method of plasticizing.

T1, T2, C = Cheeses prepared by plasticizing using Induction heating, Convection heating and hot water respectively; differing superscripted alphabets in the same row indicates significantly different (P<0.05).

Pizza cheeses having greater firmness are reported to yield higher proportion of longer shreds upon shredding [44,45].

Meltability

‘Meltability’ refers to the capacity of cheese particles to coalesce to a uniform, continuous layer of melted cheese when heated in the baking oven. The cheese must melt readily, but not excessively [46].

The result of Schreiber meltability test for cheese revealed that use of dry plasticizing techniques (T1, T2) resulted in product having significantly (P < 0.05) superior melting quality as compared to the one made using wet plasticizing (C). The two cheeses prepared using dry plasticizing had meltability values that were at par with each other (Table 8). Superior meltability associated with dry plasticized cheeses (T1, T2) could be ascribed to the use of ES, which was not the case with control cheese (devoid of ES).

Luo et al., [28] reported that Pizza cheeses prepared utilizing ES had improved meltability as compared to the one devoid of it [28]. Wang et al., [47] reported meltability of conventionally made Mozzarella cheese ranged from 3.4 to 4.0, expressed as arbitrary value. Seth et al., [48] reported meltability values of 3.8 cm and 4.1 cm for control (without ES) and processed Mozzarella cheese prepared using 1.0 % TSC respectively. Bhattarai et al., [41] reported Schrieber meltability of 5 days old Mozzarella cheese to be 4.05, expressed as arbitrary value.

Fat leakage

Fat leakage is the tendency of free oil to separate from the melted cheese mass during baking operation to form oil pockets at the cheese surface. The fat leakage values of cheeses in decreasing order were as follows: 2.83 cm2 (T2) > 1.92 cm2 (T1) > 1.35 cm2 (C); the values were significantly (P<0.05) different from each other (Table 8). Mozzarella cheeses prepared using dry plasticizing technique (T1, T2) exhibited greater fat leakage (vs. C). Unlike the findings for fat leakage of cheese in the present investigation, Seth et al., [48] reported somewhat lower fat leakage in processed Mozzarella cheese (i.e., 9.7 cm2) utilizing 1.0 % TSC as compared to that (i.e. 10.3 cm2) in conventionally made cheese counterpart. The values of fat leakage obtained in the present study was quite close to the value (minimum 2.5 cm2) suggested by Breene et al., [13] for Mozzarella cheese.

Stretchability

‘Stretchability’ is the ability of the melted Pizza cheese to form fibrous strands that elongate without breaking under moderate tension [46].

The maximum stretch (33.6 cm) was associated with cheese T1; such value was significantly (P<0.05) higher than the values associated with other two cheeses (T2, C). The latter two cheeses were at par with each other in this regard (Table 8).

The superior stretch noted for cheese T1 could be ascribed to the significantly (P<0.05) lower moisture and higher protein content (Table 7) associated with such cheese. The ratio of protein/calcium has also been implicated in determining the stretch character of Pizza cheese [49].

A minimum stretch of 3.0 inches (i.e., 7.62 cm) of unbroken string is specified for Pizza cheese in the United States [14]. Rehman et al., [50] reported stretch value of a commercial Pizza cheese to be 25.3 cm. Bhattarai et al., [41] reported stretch value of 5 days old Mozzarella cheese to be 4.50 (arbitrary value). Mizuno et al., [22] noted maximum stretch in non-fat Pasta-filata cheese prepared using 1.0 % TSC as ES as compared to use of higher levels (i.e. 3.0 and 5.0 %).

The above discussion points out at highly desirable baking characteristics of Mozzarella cheeses prepared using dry plasticizing methods, especially employing induction heating mode.

CONCLUSION

The optimized conditions for Mozzarella cheese making employing dry plasticizing method involving induction heating comprised of setting at 100 W power level and keeping a contact period of 7.0 min. with the cheese curd. The optimized conditions for Mozzarella cheese making employing convection heating comprised of setting oven temperature of 230oC and keeping a contact period of 15.0 min. with the cheese curd. It is recommended to use 0.60 % of ES blend (TSC and DSP; 3:1 w/w) for cheese curd to be treated with any of the two dry plasticizing techniques. The recovery of milk solids in Mozzarella cheese was enhanced drastically when practicing dry plasticizing of cheese curd leading to significant improvement in the cheese yield. The cheeses so obtained conformed to the FSSA standard and exhibited highly satisfactory baking properties, when used as pizza topping. The Mozzarella cheese prepared using induction heating for dry plasticizing had the best sensory quality as well as baking characteristics.

CONFLICT OF INTEREST

The authors declare no conflicts of interest.

REFERENCES

- Fox PF (1978) Direct acidification of dairy products - a review. Dairy Sci Abstr 40: 727-732.

- Shah RD, Jana AH, Solanky MJ (2008) Use of plasticizing treatment in producing pasteurized Mozzarella cheese from raw milk. J Food Sci Technol Mysore 45: 275-278.

- Enab AK, Hassan FAM, Abd El Gawad MAM (2012) Effect of manufacture steps on cheese structure (Review). Int J Acad Res 4: 79-89.

- https://www.clal.it/en/?section=tech&on=cmt-dmc.

- Nair PK (2020) New trends for low moisture part skim Mozzarella (Pizza cheese) - A review. EC Nutr 15: 1-5.

- Patel GC, Vyas, SH, Upadhyay KG (1986) Evaluation of Mozzarella cheese made from buffalo milk using direct acidification technique. Indian J Dairy Sci 39: 394-403.

- BIS (1977) Determination of fat by Gerber method. BIS-1224 (Part-I), Indian Standards Institution, Manak Bhavan, New Delhi, India Pg no. 8-9.

- Jayaraman J (1981) In: Laboratory Manual in Biochemistry 1st e Wiley Eastern Ltd: New Delhi, India, Pg no: 75-107.

- Milk Industry Foundation (1959) Methods of analysis of milk and its products. In Laboratory Manua l3rd Milk Industry Foundation, Washington, USA, Pg no: 283.

- BIS (1961) Methods of test for dairy industry. Chemical analysis of milk. BIS: 1479 (Part-II), Indian Standards Institution, Manak Bhavan, New Delhi, India, Pg no: 28.

- BIS (1979) Methods for determination of fat in cheese by Van Gaulik method. BIS: 9070. Indian Standards Institution, Manak Bhavan, New Delhi, India, Pg no: 4.

- Park J, Rosenau JR, Peleg M (1984) Comparison of four procedures of cheese meltability evaluation. J Food Sci, 49: 1158-1170.

- Breene WM, Price WV, Ernstrom CA (1964) Manufacture of pizza cheese without starter. J Dairy Sci 47: 1173-1180.

- USDA (2007) USDA Commodity requirements, MCD4 Mozzarella cheese for use in domestic programs. United States Department of Agriculture (USDA) (pg no: 1-10), Washington DC, USA.

- Moreland WC (1973) The induction range: Its performance and its development problems. IEEE Trans Indus Appl, IA-9: 81-85.

- Semiconductor Components Industries (2014) Induction cooking everything you need to know. phoenix, Estados Unidos. AND9166/D, Pg no: 1-22,

- FSSA (2017). Food Safety and Standards Act (FSSA) 2011.

- Danowska OM (2009) The influence of cooking method on the quality of pork patties. J Food Proc Preserv 33: 473-485.

- Cavalier?Salou C, Cheftel JC (1991) Emulsifying salts influence on characteristics of cheese analogs from calcium caseinate. J Food Sci 56: 1542-1547.

- Shimp LA (1985) Process cheese principles. Food Technol, 39: 63-70.

- Kapoor R, Metzger LE (2008) Process cheese: scientific and technological aspects - a review. Comp Rev Food Sci and Food Safety 7: 194-214.

- Mizuno R, Lucey JA (2005) Effects of two types of emulsifying salts on the functionality of non-fat pasta filata cheese. J Dairy Sci 88: 3411-3425.

- Patel HG, Upadhyay KG (1998) An alternate technology for manufacture of buffalo milk pizza cheese. Indian J Dairy Sci 51: 289-295.

- Gupta SK, Karahadian C, Lindsay RC (1984) Effect of emulsifier salts on textural and flavor properties of processed cheeses. J Dairy Sci 67: 764-778.

- Caric M, Gantar M, Kalab M (1985) Effects of emulsifying agents on the microstructure and other characteristics of process cheese - a review. Food Struct 4: 297-312.

- Lee SK, Buwalda RJ, Euston SR, Foegeding EA, Mc Kenna AB (2003) Changes in the rheology and microstructure of processed cheese during cooking. LWT-Food Sci Technol 36: 339-345.

- Zhong Q, Daubert CR (2004) Kinetics of rennet casein gelation at different cooling rates. J Colloid Interface Sci 279: 88-94.

- Luo J, Wang F, Ren F, Guo H (2011) Effects of emulsifying salts on functionality of Mozzarella cheese. Nongye Jixie Xuebao/Transactions of Chinese Soc Agri Mach, 42: 138-142.

- Olson N.F., & Price, W.V. (1958) A melting test for pasteurized process cheese spreads. J Dairy Sci 41: 999-1000.

- El-Gawad MA, Ahmed NS (2011) Cheese yield as affected by some parameters review. Acta Sci Pol Technol Aliment 10: 131-153.

- Kaushal K, Avinash S, Anoop S, Mukesh K, Sandeep R (2015) Effect of microwave stretching on quality attributes of Mozzarella cheese. Int J Curr Microb Applied Sci 4: 572-581.

- Najafi MBH, Arianfar A, Ghoddosi HB (2006) Study on physico?chemical, rheological and sensory properties of Mozzarella cheese made by direct acidification. Am Eurasian J Agric Environ Sci 1: 268?

- Ismail MM, Ayyad KM, Hamad MN (2007) Manufacture of Mozzarella cheese using glucono-delta-lactone. The 10th Egyptian Conference for Dairy Science and Technology, Cairo, Egypt, Pg no.: 415-432.

- El-Owni OAO, Osman SE (2009) Evaluation of chemical composition and yield of Mozzarella cheese using two different methods of processing. Pakistan J Nutr 8: 684-687.

- Zedan IA, Abou-Shaloue, Z, Zaky SM (2014) Quality evaluation of Mozzarella cheese from different milk types. Alex Sci Exc J 35:162-177.

- Farahmandfar R, Tehrani MM, Razavi SMA, Najaf MBH (2011) Effect of trisodium citrate concentration and soy cheese on meltability of pizza cheese. Int J Food Prop 14: 697-707.

- Fasale AB, Patil VS, Bornare DT (2017) Process optimization for Mozzarella cheese from cow and buffalo milk. Int J Food Ferm Technol 7: 165-173.

- Barbano DM, Yun JJ, Kindstedt PS (1994) Mozzarella cheese making by a stirred curd, no brine procedure. J Dairy Sci 77: 2687-2694.

- Sameen A, Anjum FM, Huma N, Kousar R, Nawaz H (2008) Impact of fat levels in milk on the composition, sensory attributes and functionality of buffalo Mozzarella cheese. Pakistan J Agri Sci 45: 463-469.

- Demott BJ (1983) Recovery of milk constituents in a Mozzarella-like product manufactured from non-fat dry milk and cream by direct acidification at 4 and 35o J Dairy Sci 66: 2501-2506.

- Bhattarai RR, Acharya PP (2010) Preparation and quality evaluation of Mozzarella cheese from different milk sources. J Food Sci Technol Nepal 6: 94-101.

- Sabikhi L, Kanawjia SK (1992) Effect of admixing of goat and buffalo milks on sensory, compositional and textural characteristics of direct acid Mozzarella cheese. Indian J Dairy Sci 45: 562-569.

- Apostolopoulos C, Marshall RJ (1991) Functional properties of Mozzarella cheese as a pizza topping. Report produced for European Economic Community. Agricultural and Food Research Council (AFRC), Institute of Food Research, Reading University, UK.

- Banville V, Morin P, Pouliot Y, Britten M (2014) Shreddability of pizza Mozzarella cheese predicted using physico-chemical properties. J Dairy Sci 97: 4097-4110.

- Joshi NS, Muthukumarappan K, Dave RI (2004) Effect of calcium on microstructure and meltability of part skim Mozzarella cheese. J Dairy Sci 87: 1975-1985.

- Jana AH, Tagalpallewar GP (2017) Functional properties of Mozzarella cheese for its end use application. J Food Sci Technol 54: 3766-3778.

- Wang HH, Sun DW (2002) Correlation between cheese meltability determined with a computer vision method and with Arnott and Schreiber tests. J Food Sci 67: 745-749.

- Seth K, Bajwa U (2015). Effect of acidulants on the recovery of milk constituents and quality of Mozzarella processed cheese. J Food Sci Technol 52: 1561-1569.

- Lucey JA, Fox PF (1993) Importance of calcium and phosphate in cheese manufacture: A review. J Dairy Sci 76: 1714-1724.

- Piggott JR, Ahmad MM, Hussain S, Ahmad N, Owusu?Darko P (2008) Preparation and evaluation of pizza cheese made from blend of vetch–bovine milk. Int J Food Sci Technol 43: 770-778.

Citation: Patel A, Jana A, Parmar S, Modha H (2020) Process Standardization and Characterization of Mozzarella Cheeses Prepared Using Dry Plasticizing Techniques. J Dairy Res Tech 3: 015.

Copyright: © 2020 Patel Akash, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.