Quality and Shelf Life of Snack Food as Influenced by Incorporation of High Protein Pulses in Multipurpose Flour

*Corresponding Author(s):

Saghir AhmadDepartment Of Post Harvest Engineering And Technology, Aligarh Muslim University, Aligarh, Uttar Pradesh, India

Tel:+919412601092,

Email:alsaghirqadri@gmail.com

Abstract

The present study was conducted on development, quality evaluation of snack food prepared with multipurpose flour, namely wheat flour, gram flour, moong flour and urad flour, fried in refined and sunflower oil. The ultimate purpose of incorporation of urad flour and moong flour in the wheat and gram flour was to increase nutritional value of snack food. The urad and moong flour which are very rich in essential amino acid especially lysine, protein content and minerals was taken for incorporation as a substitute of highly priced protein food that will be obtained from animal sources. These flours also contain large amount of carbohydrates thus provide high energy. Eight snack food samples were prepared by the combination of different flour fried in different oil sources. The snack food prepared by the combination of wheat and gram flour has higher fat content. The urad flour and moong flour were incorporated in different proportion (2.5%, 5%, 7.5%). The fat content of control samples was found between 26.82 to 33.11% (fried in mustard oil) and 23.30 to 30.71 (fried in sunflower oil) during 90 days of ambient storage. The pH value of snack food sample treated with 7.5% moong-urad flour(each) was found between 6.68 to 7.15 (fried in mustard oil) and 6.73 to 7.18 (fried in sunflower oil) at the end of 90 days of ambient storage. It has been noticed that the snack food samples fried in refined oil is of higher nutritional values than snack food samples fried in sunflower oil.

Keywords

INTRODUCTION

A snack is a portion of food of ten times smaller than that of a regular meal that is generally eaten between meals. Snacks come in a variety of forms including packaged and processed foods and items made from fresh ingredients at home. The pear millet is comparable and even superior in some of the nutritional characteristics to major cereals with respect to its energy value, protein, fat and minerals [1]. Plain snacks like plain cereals, pasta and vegetables are also mildly popular, and the word snack has often been used to refer to a larger meal involving cooked or leftover items. Six-meal eating is a form of eating that interjects healthy snacks in between small meals, to stave off hunger and promote weight loss. With growing concerns for diet, weight control and general health, government bodies like Health Canada are recommending that people make a conscious effort to eat more healthy, natural snacks- such as fruit, vegetables, nuts and cereal grains- while avoiding high-calorie, low-nutrient junk food. The growth of bakery industry is about 10% per annum and the products are increasingly becoming popular among all sections of people [2]. The use of millet flour is becoming more common in baked products especially in bread, cookies and crackers that are targeted at consumers who are gluten sensitive or diabetic [3]. The extruded ready to eat sweet and savory snacks developed using maize, green gram dhal and roasted bengal gram dhal in addition to enrichment with vitamin and iron [4]. Total fourteen commonly consumed traditional Indian bengal gram flour based snacks reported [5]. Deep fat frying is an important unit operation, which can be considered as the combination of frying and cooking. Several chemical and physical changes occur during the frying such as starch gelatinization, protein denaturation and crust formation. The amount of moisture in the deep-fried potatoes, evaporated was proportional to the square root of frying time. Snack food based on cereals and grains are low in nutrient density, high in calories and fat content and lack some essential amino acids like threonine, tryptophan and lysine [6]. Total eight varieties of traditional rice based snacks Pumaloi, Pudoh, Jashulia, Puthalo, Pukhlien, Pusaw, Pusla and Putyndong from Shillong and villages in the Ri-bhoi district [7]. Model systems for crust less and crust forming products, the amount of moisture evaporated was observed proportional to to the square root of frying time [8]. The variation in the moisture and oil contents of samples of 1.5 mm thick slices of 145ºC, 165ºC & 185ºC as a function of time and the moisture loss & oil uptake were found to be interrelated [9]. The oil content in sev was recorded minimum when fried in cottonseed oil [10]. The market is estimated at US$ 3 billion, with 50 percent comprising the organized snacks category. This category, growing at a healthy 30 percent annually, is sub-divided into the traditional segment (bhujia, chanachur), western segment (potato chips, cheese balls) and the newly established finger snacks segment, an adaptation of traditional offerings to the western format. The market in India is diverse and large with over 1,000 different snack products and some 300 types of savories. Potato-based snacks, and in particular potato chips, are the largest product segment, holding an 85 percent share of the salty snack market, followed by snack nuts, chickpeas and other pulse-based savory snacks. Organized retail chains have high demand for popcorn, diet snacks (soy nuts, bread sticks), breakfast cereals, baked and roasted snacks (biscuits, specialty breads, chocolate coated snacks, cookies etc.) and cheese snacks. Health foods, health food supplements and convenient foods are also rapidly growing segments. The Indian snacks market is worth around US$ 3 billion, with the organized segment taking half the market share, and has an annual growth rate of 15-20 per cent. The unorganized snacks market is worth US$ 1.56 billion, with a growth rate of 7-8 per cent per year. It should also be pointed out that the consumption of snack foods does not necessarily lead to health problems such as obesity, but the cause is rather an unbalanced diet with excess fat, sugar, and salt. In the light of above discussion, a study on the development of snack food was undertaken with the objectives of investigation as given below. It was to develop and study the quality & stability of snack food with multipurpose flour incorporated with moong and urad flour.

MATERIALS AND METHODS

Methods of preparation of snack food

| Sample Code | Moong Flour % | Urad Flour % | MPF (Wheat Flour: Gram Flour |

| S1 | 0 | 0 | 1:1 |

| S2 | 2.5 | 2.5 | 1:1 |

| S3 | 5 | 5 | 1:1 |

| S4 | 7.5 | 7.5 | 1:1 |

| M1 | 0 | 0 | 1:1 |

| M2 | 2.5 | 2.5 | 1:1 |

| M3 | 5 | 5 | 1:1 |

| M4 | 7.5 | 7.5 | 1:1 |

| Sample Code | Protein Content in the Formulations (In Grams per 500 g of Sample) | Protein Content in the Formulations (%) |

| S1 | 88.47 | 17.694 |

| S2 | 89.92 | 17.98 |

| S3 | 91.60 | 18.32 |

| S4 | 93.15 | 18.63 |

| M1 | 88.47 | 17.694 |

| M2 | 89.92 | 17.98 |

| M3 | 91.60 | 18.32 |

| M4 | 93.15 | 18.63 |

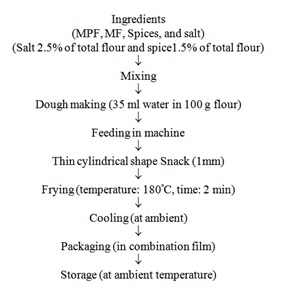

Flow Chart 1: Process flow chart for preparation of snack food.

Flow Chart 1: Process flow chart for preparation of snack food.Physicochemical properties

Moisture content

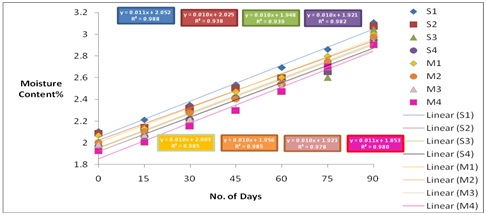

Figure 1: Evaluation of moisture content of snack food samples (control and incorporated with different levels of moong-urad flour) during ambient storage.

Figure 1: Evaluation of moisture content of snack food samples (control and incorporated with different levels of moong-urad flour) during ambient storage.Fat content

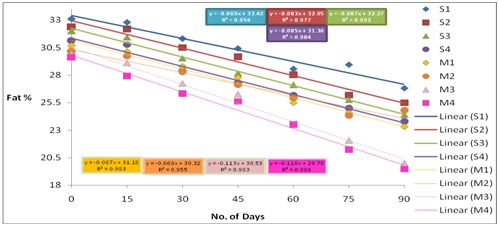

Figure 2: Evaluation of fat content of snack food samples (control and incorporated with different levels of moong-urad flour) during ambient storage.

Figure 2: Evaluation of fat content of snack food samples (control and incorporated with different levels of moong-urad flour) during ambient storage.pH value

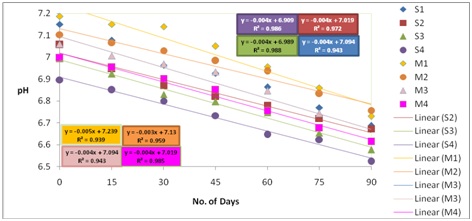

Figure 3: Evaluation of pH value of snack food samples (control and incorporated with different levels of moong-urad flour) during ambient storage.

Figure 3: Evaluation of pH value of snack food samples (control and incorporated with different levels of moong-urad flour) during ambient storage.Ash content

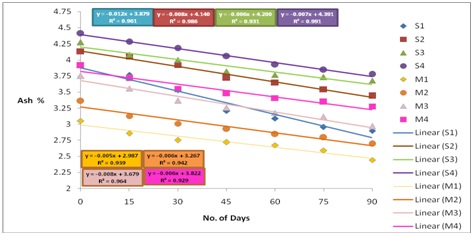

Figure 4: Evaluation of ash content of snack food samples (control and incorporated with different levels of moong-urad flour) during ambient storage.

Figure 4: Evaluation of ash content of snack food samples (control and incorporated with different levels of moong-urad flour) during ambient storage.Free fatty acids

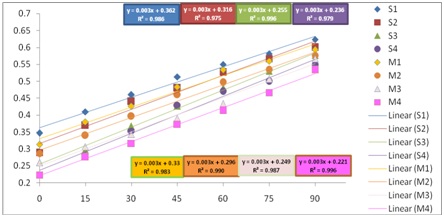

Figure 5: Evaluation of free fatty acids of snack food samples (control and incorporated with different levels of moong-urad flour) during ambient storage.

Figure 5: Evaluation of free fatty acids of snack food samples (control and incorporated with different levels of moong-urad flour) during ambient storage.Thiobarbituric acid test

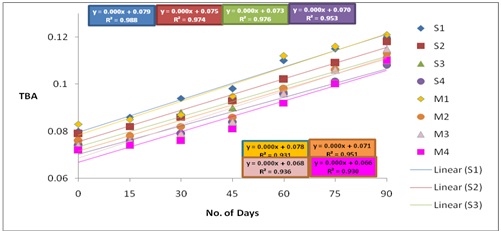

Figure 6: Evaluation of TBA value of snack food samples (control and incorporated with different levels of moong-urad flour) during ambient storage.

Figure 6: Evaluation of TBA value of snack food samples (control and incorporated with different levels of moong-urad flour) during ambient storage.Peroxide value

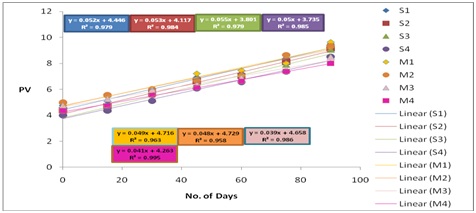

Figure 7: Evaluation of Peroxide value of snack food samples (control and incorporated with different levels of moong-urad flour) during ambient storage.

Figure 7: Evaluation of Peroxide value of snack food samples (control and incorporated with different levels of moong-urad flour) during ambient storage.STATISTICAL ANALYSIS

X= Mean of individual

n= Total population of sample

S = Error of total sum of deviation squares

n = No. of replications

t = Value at 0.05 obtained at the degree of freedom

RESULTS & DISCUSSION

The results of physicochemical properties of fresh snack food samples have been given in table 3. The fresh snack food samples M1, M2, M3, M,, S1, S2, S3, and S4 prepared from multipurpose flour and different proportion of moong and urad flour has the moisture content 2.10%, 2.09%, 2.00%, 1.97%, 2.07%, 2.00%, 1.98% and 1.92% respectively as shown in the figure 1. The sample S4 prepared with 7.5% moong and urad flour fried in sunflower oil had lowest moisture content (1.92%) of all the remaining snack food samples based on only Multipurpose Flour (MPF) and multipurpose flour incorporated with 2.5%, 5% and 7.5% each of moong and urad flour fried in mustard oil and sunflower oil. Treatment of moong-urad flour significantly (p<0.05) decreased moisture content of snack food samples. Similar results men also obtained by Labuza and Schimidt (1985) who suggested that moisture absorption might be due to storage condition and air available inside packaging material. Initially fat contents of all snack food samples were found in the range of 29.51 to 33.05% (Table 3). The fat content of snack food sample S1 was found to be 33.05%, which was higher as compared to remaining snack food samples prepared from combination of multipurpose flour incorporated with different levels of moong-urad flour namely S2, S3, S4, M1, M2, M3 and M4 (The samples S2, S3, S4, M1, M2, M3 and M4 had 32.34%, 31.91%, 31.01%, 30.71%, 30.28%, 30.01% & 29.51% fat content respectively as shown in the figure 2). Treatment of moong-urad flour significantly (p<0.05) decreased fat content of snack food samples. The pH values, of eight different fresh samples of snack food were found between 7.01 to 7.18. The pH value of snack food sample (M1) was 7.18, which was higher as compared to remaining snack food samples S1, S2, S3, S4, M2, M3 and M4 prepared from MPF incorporated with different levels of moong-urad flour. The pH values of snack food samples S1, S2, S3, S4, M2, M3 and M4 were found to be 7.14, 7.04, 6.98, 6.90, 7.09, 7.06 and 7.01 respectively as shown in the figure 3. As incorporation of moong-urad flour, pH value decreased because pH of moong-urad flour was found less than pH of MPF. Therefore treatment of moong-urad flour significantly (p<0.05) decreased the pH of the snack food samples. Ash contents, of eight different samples of snack food were found between 3.04 to 4.40%. The ash content of snack food samples S4 was 4.40%, which was higher as compared to remaining snack food samples S1, S2, S3, M1, M2, M3 and M4 prepared from multipurpose flour incorporated with different levels of moong-urad flour. The ash contents of snack food samples S1, S2, S3, M1 M2, M3 and M4 were found to be 3.91%, 4.13%, 4.24%, 3.04%, 3.35%, 3.75% and 3.89% respectively as shown in the figure 4. Treatment of moong-urad flour significantly (p<0.05) increased the ash content of snack food sample. The FFA contents of snack food samples were found between 0.24 to 0.35% oleic acids. The FFA contents of snack food sample S1 was found 0.35% of oleic acids. It was higher as compared to remaining snack food samples prepared from multipurpose flour incorporated with different levels of moong-urad flour. The FFA content of snack food samples S2, S3, S4, M1, M2, M3 and M4 treated with moong-urad flour were found 0.30%, 0.26%, 0.24%, 0.31%, 0.29%, 0.26% and 0.0.24% of oleic acid respectively as shown in the figure 5. As moong-urad flour has low fat content and moisture content, which helped in preventing oxidation of fat into fatty acids. It was due to antioxidant property of moong flour. Therefore, treatment of moong flour significantly (p<0.05) decreased FFA of snack food samples. The peroxide values of eight different snack food samples were found between 4.36 to 6.73 meq O2 per kg fat, which was found under safe limit. The peroxide value of snack food samples S1 was 6.73 meq O2 per kg, which was higher as compared to other snack food samples S2, S3, S4, M1, M2, M3 and M4 treated with moong-urad flour (The PV of snack food samples S2, S3, S4, M1, M2, M3 and M4 were found 6.39, 6.16, 5.99, 5.23, 4.99, 4.73 and 4.36 meq O2 per kg respectively as shown in the figure 7). This was due to antioxidant property of moong flour. Therefore, treatment of moong flour significantly (p<0.05) decreased PV of snack food samples. The TBA numbers of snack food samples in fresh condition were found between 0.072 to 0.080 mg/ kg of malonaldehyde. The TBA value for snack food sample S1 was found to be 0.080 mg/kg of malonaldehyde, which was more than TBA value of snack food samples S2, S3, S4, M¬¬1, M2, M3 and M4 prepared from combination of multipurpose flour incorporated with different levels of moong-urad flour (The TBA number of snack food samples were 0.079, 0.076, 0.074, 0.73 and 0.72 mg/kg of malonaldehyde respectively as shown in the figure 6). Treatment of moong flour significantly (p<0.05) decreased TBA number of snack food samples.

| Constituent | Sample code | |||||||

| S1 | S2 | S3 | S4 | M1 | M2 | M3 | M4 | |

| Moisture content, % | 2.10±0.01 | 2.09±0.01 | 2.00±0.01 | 1.97±0.02 | 2.07±0.02 | 2.00±0.01 | 1.98±0.02 | 1.92±0.02 |

| Fat content, % | 33.11±0.06 | 32.36±0.98 | 32.01±0.09 | 31.13±0.10 | 30.71±0.20 | 30.15±0.11 | 29.90±0.10 | 29.60±0.09 |

| pH value | 7.15±0.01 | 7.05±0.01 | 6.99±0.01 | 6.89±0.02 | 7.18±0.01 | 7.10±0.01 | 6.99±0.02 | 7.07±0.02 |

| Ash content, % | 3.90±0.05 | 4.13±0.01 | 4.27±0.03 | 4.41±0.03 | 3.05±0.05 | 3.36±0.02 | 3.75±0.05 | 3.91±0.03 |

| FFA, % | 0.34±0.02 | 0.29±0.03 | 0.26±0.03 | 0.22±0.03 | 0.31±0.02 | 0.28±0.03 | 0.26±0.02 | 0.22±0.01 |

| PVmeq O2/kg | 4.73±0.01 | 4.39±0.01 | 4.16±0.01 | 3.99±0.02 | 4.89±0.01 | 4.99±0.01 | 4.73±0.01 | 4.36±0.02 |

| TBAnumber | 0.080±0.06 | 0.079±0.02 | 0.076±0.01 | 0.074±0.01 | 0.087±0.01 | 0.088±0.01 | 0.086±0.01 | 0.081±0.01 |

Table 3: Physicochemical properties of snack food prepared from MPF and Moong-Urad flour (in fresh condition).

CONCLUSION

The snack food samples of high nutrient density were prepared from multipurpose flour incorporated with different levels of moong flour and urad flour. The composition and nutritive value of snack food samples based on wheat flour, gram flour, urad and moong flour represented balanced quantity of carbohydrate, protein, minerals, fat, dietary fiber, and these samples were acceptable in sensory evaluation. Since the moong and urad flour has high level of protein, minerals and phenolic compounds, which acts as strong antioxidant. The peroxide value, FFA and TBA number were found to be in safe range and there were no sign of deterioration in snack food samples after 90 days of ambient storage. These snack food samples could be of great help in improving the health of snack food consumers by serving as good supplements and provide a new way of consumption of such legumes, which cannot be consumed directly but has high nutritive value.

ACKNOWLEDGEMENT

Authors are thankfully acknowledges the Department of Post Harvest Engineering & Technology, Aligarh Muslim University, Aligarh city of Uttar Pradesh (India) for extending the research facilities to complete the experimental work related to the objective of the investigation.

REFERENCES

- Abdalla AA, Tinay AHE, Mohamed BE, Abdalla AH (1998) Proximate composition, starch and mineral contents of 10 pearl millet genotypes. Food Chem 63: 243-246.

- Indrani S, Savithri GD, Venkateswara RG (1997) Effect of defatted soy flour on the quality of buns. J Food Sci Technol 34: 440-442.

- Lovis LJ (2003) Alternatives to wheat flour in baked goods. Cereal Food World 48: 61-63.

- Devi L, Khader V, Rao M (2005) Development and acceptability of ready to eat snack for the institutionalized elderly. J Food Sci Technol 42: 176-179.

- Ankleshwarla NT, Karkar PD (2001) Studies on sodium and potassium content of traditional bengal gram flour based snacks. Indian Food Packer 137.

- Jean IJ, Work R, Camire ME, Briggs J, Barrett AH et al. (1996) Selected properties of extruded potato and chicken meat. J Food Sci Technol 61: 783-789.

- Agrahar MD, Subbulakshmi G (2005) Nutritional evaluation and processing methods of some traditional snacks consumed by the khasi tribals of Meghalaya. J Food Sci Technol 42: 255-258.

- Mittelman AN, Mizrahi S, Brek Z (1984) Heat and mass transfer in frying: In: Mckenna BD (ed.). Engineering and Food: Engineering sciences in the food industry. Elseveir Applied Science Publication Amsterdam, Netherlands.

- Gamble MH, Rice P, Selman JD (1987) Relationship between oil uptake and moisture loss during frying of potato slice from c.v record U.K tubers. Int J Food Sci Technol 22: 233-241.

- Annapure US, Singhal RS, Kulkarni PR (1998) Studies on deep-fat fried snacks from some cereals and legumes. Journal of the Science of Food and Agriculture 76: 377-382.

- Mandal, RC, Nambian PTN (1999) Analysis of covariance in agricultural statistics techniques and procedures. Agro Botanical Publishing, Bikaner, India. Pg no: 135-139.

Citation: Ahmad S, Ashraf K, Khan I (2017) Quality and Shelf Life of Snack Food as Influenced by Incorporation of High Protein Pulses in Multipurpose Flour. J Food Sci Nut 3: 019.

Copyright: © 2017 Saghir Ahmad, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.