Recent Progress in the Role of Fermentation in Plant-Based Foods: A Concise Review

*Corresponding Author(s):

Nazanin AbbaspourFamily Health Centers Of San Diego, 823 Gateway Center Way San Diego, California, United States

Email:naz.abbaspour@gmail.com

Abstract

The global food industry is experiencing a transformative shift towards alternative foods driven by sustainability concerns and evolving consumer preferences. This paper explores fermentation's pivotal role in shaping the landscape of alternative foods, exploring its historical significance, fundamental principles, and contemporary applications. Fermentation, an ancient biological process, involves the enzymatic conversion of carbohydrates into diverse compounds by microorganisms such as yeast and bacteria, and even in oxygen-starved muscle cells, as seen in lactic acid fermentation. Beyond its biological roots, fermentation extends to the large-scale cultivation of microorganisms in controlled environments, crucial for producing various products like enzymes, vaccines, antibiotics, and food additives. This transformation from a method for preserving household food to a sophisticated technology has been made possible through advancements in microbiology, biotechnology, process engineering, process control, and instrumentation over the past century. We review advances in alcoholic fermentation, lactic acid fermentation, acetic acid fermentation, propionic acid fermentation, and butyric acid fermentation and explore future developments in fermentation. As the alternative food sector gains momentum, fermentation emerges as a transformative technology capable of revolutionizing global food systems, addressing sustainability challenges, and offering innovative solutions to pressing issues.

This research delves into the ancient fermentation practice, where microorganisms like yeast and bacteria transform carbohydrates into diverse compounds. Beyond its historical roots in preserving household food, modern advancements in microbiology and biotechnology have elevated fermentation to a sophisticated technology. This transformative process is now essential in large-scale production, contributing to the creation of various products such as enzymes, vaccines, antibiotics, and food additives. With the global shift towards alternative foods for sustainability, fermentation emerges as a vital technology, revolutionizing the food industry and offering innovative solutions to pressing challenges.

Keywords

Acetic acid fermentation; Alcoholic fermentation; Butyric acid fermentation; Environmental sustainability; Food security; Lactic acid fermentation; Propionic acid fermentation

Introduction

Conventional agriculture and animal husbandry have been scrutinized due to their adverse environmental effects, ethical quandaries, and the urgency to confront food security issues. Non-animal-based foods have emerged as a dynamic and promising solution to these critical concerns. In a recent study, we aimed to clarify terminology-related confusion by categorizing the diverse range of plant-based foods emerging as alternatives to traditional animal-derived counterparts. We differentiated these options based on their level of processing and functional properties, referring to them as "alternatives," "substitutes," "replacements," and "analogs" [1] (Table 1). Fermentation improves protein digestibility and mineral bioavailability in foods such as tempeh, resulting in nutritional values compatible with meat, and is anticipated to become pivotal in sustainable food production [2]. This biological process, refined over the years and enhanced with modern technologies, is vital in the rising demand for proteins and eco-friendly food production methods.

|

Terms |

Definition |

Examples |

|

Substitute |

A plant-based food or ingredient that can substitute the original animal-sourced food or ingredient outside or within a recipe. When used in a recipe, a substitute should be similar, if not identical, in its culinary properties to the original ingredient. |

- Bean patties: Vegetarian or vegan burger patties made primarily from mashed beans, such as black beans, kidney beans, chickpeas, and other ingredients such as vegetables, grains, and spices. - Plant-based milk (e.g., nut milk, oat milk, coconut milk, hemp milk): The nutritional values of these products vary from dairy milk, except for soymilk; however, they typically have physicochemical and sensory properties similar to cow's milk. - Vegetable oil: Can be used as a substitute for butter in baking and cooking, contributing to tenderness. |

|

Replacement |

It is a plant-based option with similar nutritional properties to its animal-based counterpart. The focus here is the key nutrients in the animal-based food or ingredient, and the functional and sensory attributes are secondary considerations. |

- Tofu: A minimally processed soybean product that provides high-quality plant-based protein similar to animal protein. - Tempeh: Another soy product made from partially cooked, fermented soybeans |

|

Analog

|

Refers to a plant-based product that intends to match its animal food counterpart's nutritional and culinary attributes. The aim is to re-create the original animal food in terms of appearance, texture, flavor, mouthfeel, and other sensory qualities while meeting its nutritional and functional properties. |

- Soymilk: Nutritionally, it is the closest to dairy milk. It is the only plant-based milk with comparable amounts of protein, minerals, and vitamins to cow's milk. - First-generation meat analogs: Plant-based food products that mimic meat's texture, taste, and appearance. - Second-generation meat analogs: A type of non-animal-based meat that aims to replicate the texture, flavor, and appearance of real meat more closely than earlier-generation products |

|

Alternative |

Refers to a food option that does not attempt to replicate its animal-based counterpart's nutritional and culinary qualities. An alternative is a choice with similar physical characteristics to the original animal-based food, such as texture or form. |

- Drinking apple juice as an alternative to milk. - Using avocado and nuts instead of cheese and salami as part of a charcuterie board. - An entrée of pasta and vegetables instead of beef stew for dinner. |

Table 1: Definition of different terms used for animal food replacement products and their related examples.

The World Economic Forum [3], anticipates a 100% increase in protein demand by 2050, a need that cannot be met solely with animal proteins due to environmental and ethical concerns. Fermentation offers a viable solution, with companies like Quorn's and Clara Food and 66 other companies leveraging microbial, biomass, and precision fermentation to create meatless and egg protein products.

Traditional fermentation, which depends on natural microorganism processes and environmental conditions, has been optimized and standardized with technology [4]. The modern advancements in biomass and precision fermentation allow for large-scale, precise food production, bridging the gap between artisanal and industrial needs. These techniques result in end products like cheese or bread and contribute essential ingredients to plant-based and cultivated foods [5].

Plant-based meat analogs, fortified through fermentation, address environmental and health concerns associated with animal meat consumption. However, the rush to enhance their sensory attributes often overshadows nutritional and safety considerations. Fermentation, especially with specific microorganisms like Bacillus subtilis and Lactiplantibacillus plantarum, enhances the digestibility, reduces allergenicity, and augments the nutritional content of plant-based meat, addressing these concerns.

In the era of sustainable food production, fermentation stands as a cornerstone. It supports the creation of diverse food products and promises to resolve the impending protein crisis while adhering to environmental and health protocols. The evolution from traditional to precision fermentation signifies the adaptation of this ancient technique to modern-day needs, underscoring its relevance and potential in future food production landscapes.

The Process Of Fermentation

Fermentation is a biological process humans have harnessed for millennia [6]. A metabolic pathway allows microorganisms like yeast, bacteria, and sometimes fungi to convert carbohydrates (sugars and starches) into other compounds, such as alcohol or organic acids. This process is crucial in human life, from food and beverage production to pharmaceuticals and biofuel generation.

The dedicated field that delves into fermentation study is known as zymology. Fermentation primarily works without oxygen when the electron transport chain remains idle. Here, it serves as the cell's principal method of generating Adenosine Triphosphate (ATP), the driver of energy in many cellular processes. In this process, NADH, the energy generator, and pyruvate, the end products of glycolysis, metamorphose into NAD+ and an array of small molecules, the precise nature of which depends on the particular type of fermentation. Conversely, when oxygen enters the cellular stage, NADH and pyruvate take center stage in cellular respiration, orchestrated through oxidative phosphorylation. This elaborate process yields a significantly greater ATP than glycolysis in isolation. Hence, when the oxygen supply is abundant, cells favor respiration over fermentation, except for obligate anaerobes that shun the oxygen-rich environs by their very nature [7].

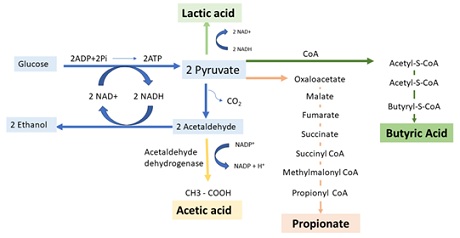

This article presents a comprehensive review of advancements in diverse fermentation processes, encompassing alcoholic, lactic acid, acetic acid, propionic acid, and butyric acid fermentation. Figure 1 encapsulates the journey from glucose to pyruvate and further conversion to acetic acid, lactic acid, propionate, and butyric acid. Additionally, the article explores upcoming developments in the fermentation domain.

Figure 1: Alcoholic fermentation: Glycolysis of one glucose yields two pyruvate molecules, leading to the production of ethanol through the reduction of acetaldehyde by two NADH, regenerating NAD+.

Lactic acid fermentation: In anaerobic conditions, pyruvate is reduced to lactic acid by NADH, which is crucial for NAD+ regeneration and sustaining glycolysis. This process is prevalent in certain bacteria, yeast, and oxygen-limited muscle cells.

Propionate synthesis: Microbial metabolism converts pyruvate to propionate through a series of enzymatic transformations involving oxaloacetate, malate, fumarate, succinate, succinyl CoA, methylmalonyl CoA, and finally propionyl CoA.

Butyric acid pathway: Pyruvate decarboxylation to acetyl-S-CoA initiates the path to butyric acid. Acetyl-S-CoA elongates to butyryl-S-CoA, which is then reduced to butyric acid, showcasing microbial metabolic versatility in butyric acid synthesis.

Alcoholic Fermentation

Alcoholic fermentation, a millennia-old process, transforms sugars into ethanol and carbon dioxide, shaping cultures and economies [6]. Beyond its historical roots, it drives modern industries, including brewing and winemaking. Alcoholic fermentation, led by yeast, plays a crucial role in producing beverages and extends to industrial applications, offering an eco-friendly alternative to fossil fuels. The process, orchestrated by Saccharomyces cerevisiae, involves glycolysis and the formation of ethanol and carbon dioxide [8]. Advances in winemaking technologies, from fermentation control systems to precision viticulture, enhance quality and flavor precision [9]. Ongoing research in microbiology and genetic engineering propels innovations, from low-alcohol beverages to bioengineered yeast for sustainable biofuel production [10-12].

Kefir and kumys are fermented milk products involving alcoholic fermentation. Kefir, produced by fermenting milk with kefir grains or starter microorganisms, consists of lactic acid bacteria, acetic acid bacteria, and yeasts [13]. During fermentation, it generates lactic acid, acetic acid, ethanol, and various beneficial compounds. Kefir exhibits antimicrobial activity, particularly against bacteria, attributed to bioactive substances. In contrast, kumys is made by fermenting mare's milk in two stages, including alcoholic fermentation. Fermentation produces lactic acid, ethyl alcohol, carbon dioxide, and other by-products. Kumys inhibits the growth of pathogenic bacteria, and its microbiota transition from raw mare's milk contributes to increased food hygiene and reduced infection risk. Alcoholic fermentation in kefir and kumys yields products with distinct qualities and potential health benefits [14].

Application of Alcoholic Fermentation in Plant-Based Foods

Alcoholic fermentation plays a significant role in producing various plant-based foods, contributing to flavor development and preservation [14]. This fermentation process involves the conversion of sugars into alcohol and carbon dioxide by yeast or other microorganisms. Some key aspects of the role of alcoholic fermentation in plant-based foods are listed below. Table 2 provides a summary of the important elements in various fermentations.

|

Reference |

Summary of Finding |

|

Application of Alcoholic Fermentation in Plant-Based Foods |

|

|

Siddiqui et al. [14] |

Alcoholic fermentation is vital in producing various plant-based foods, contributing to flavor development and preservation. The process involves converting sugars into alcohol and carbon dioxide by yeast or other microorganisms. |

|

Maicas [15] |

In bread making, alcoholic fermentation is a crucial step. Yeast ferments sugar in flour, producing carbon dioxide, which causes the dough to rise. This leavening process creates air pockets, giving bread a light and airy texture. |

|

Dimidi et al. [16] |

During the preparation of fermented cabbage products like sauerkraut and kimchi, alcoholic fermentation occurs alongside lactic acid fermentation. Sugars in cabbage are converted into alcohol by yeast and then into lactic acid by bacteria, imparting a tangy flavor and enhancing shelf life. |

|

Satora et al. [17] |

The dual fermentation process in sauerkraut and kimchi (alcoholic and lactic acid fermentation) is important for flavor development and preservation. |

|

Sofo et al. [18] |

Alcoholic fermentation is an essential stage in creating sourdough bread. Wild yeast in the flour or a sourdough starter ferments the sugars, producing carbon dioxide and alcohol. The carbon dioxide helps the dough rise, while the alcohol contributes to the bread's unique flavor. |

|

Chong et al. [19] |

Alcoholic fermentation produces plant-based fermented beverages like ginger beer and kombucha. Yeast ferments the sugars in ingredients like ginger or sweetened tea, producing alcohol and carbonation. |

|

Devanthi et al. [20] |

In soy sauce production, a fermentation process that includes alcoholic fermentation occurs. Yeast and lactic acid bacteria break down complex compounds in soybeans, leading to alcohol production and the development of a rich umami flavor. |

|

Application of Lactic Acid Fermentation in Plant-Based Foods |

|

|

Dimidi et al. [16] |

Lactic acid fermentation is used in preparing fermented vegetables like pickles, sauerkraut, and kimchi, converting sugars into lactic acid, adding a tangy flavor, and acting as a natural preservative. |

|

Dimidi et al. [16] |

Lactic acid bacteria in sourdough bread break down sugars, producing lactic acid, which enhances flavor and aids in leavening by creating an environment conducive to yeast activity. |

|

Montemurro et al. [21] |

Plant-based yogurts use lactic acid fermentation with microorganisms like Lactobacillus bulgaricus and Streptococcus thermophilus, converting sugars in plant-based milk alternatives to lactic acid, adding tanginess and a creamy texture. |

|

Dimidi et al. [16] |

Lactic acid fermentation produces fermented beverages like kefir and certain fruit juices, contributing to a tangy flavor profile. |

|

Romulo and Surya [22] |

In tempeh production, Rhizopus molds ferment soybeans, producing lactic acid, among other compounds, leading to a unique texture, flavor, and enhanced nutritional profile. |

|

Boukid et al. [23] |

Lactic acid fermentation is applied to develop fermented plant-based protein products, improve digestibility, reduce anti-nutritional factors, and enhance nutritional quality. |

|

Knez et al. [24] |

Lactic acid fermentation can increase nutrient bioavailability in plant-based foods by breaking down compounds like phytates, making minerals more accessible for absorption. |

|

Application of Acetic Acid fermentation in plant-based foods |

|

|

Yassunaka Hata et al. [25] |

Vinegar production is a primary application of acetic acid fermentation. Acetic acid bacteria, particularly Acetobacter species, convert ethanol into acetic acid in various plant-based sources, creating vinegar with a tangy flavor, used as a condiment and preservative. |

|

Yassunaka Hata et al. [25] |

Kombucha undergoes acetic acid fermentation. Acetic acid bacteria convert sugars from tea into acetic acid, giving kombucha its sourness and acting as a preservative. |

|

Yassunaka Hata et al. [25] |

Acetic acid fermentation produces fermented condiments like hot sauces and mustard. Acetic acid bacteria ferment peppers, fruits, or mustard seeds, enhancing preservation and flavor development. |

|

Yassunaka Hata et al. [25] |

Acetic acid fermentation involves fermenting plant-based grains, like in rice vinegar production or traditional fermented foods, where sugars are transformed into acetic acid. |

|

Leeuwendaal et al. [26] |

The acidic environment created by acetic acid fermentation enhances the safety of plant-based foods by inhibiting pathogenic bacteria, contributing to extended shelf life. |

|

Nkhata et al. [27] |

Acetic acid fermentation can improve the digestibility and bioavailability of nutrients in plant-based foods. |

|

Application of Acetic Acid fermentation in plant-based foods |

|

|

Genet et al. [28] |

Propionic acid fermentation may produce Swiss cheese analogs in the plant-based food industry. Fermentation of plant-based milk alternatives with specific bacteria could mimic the flavor of traditional Swiss cheese. |

|

Tangyu et al. [29] |

Propionic acid and its salts (calcium and sodium propionate) are used as preservatives in plant-based baked goods or snacks to inhibit mold and bacterial growth, contributing to extended shelf life. |

|

Gonzalez-Garcia et al. [30]; Ranaei et al. [31] |

Propionic acid fermentation might be used in bioprocessing plant-based raw materials, utilizing bacteria to ferment plant-derived sugars or substrates, influencing the flavor and preservation of the final product. |

|

Illikoud et al. [32] |

Propionic acid fermentation could enhance organoleptic qualities and contribute to unique flavor development in developing fermented plant-based protein products. |

|

Elhalis et al. [33] |

Propionic acid fermentation has biotechnological applications in developing plant-based food ingredients or additives, providing specific flavors or functional properties. |

|

Application of Butyric Acid fermentation in plant-based foods |

|

|

Stanzer et al. [34] |

Butyric acid may enhance plant-based foods' buttery aroma and taste, especially those replicating dairy flavors. |

|

Horlacher et al. [35] |

Butyric acid fermentation could produce plant-based milk alternatives, offering a unique flavor profile and potentially richer taste than lactic acid fermentation. |

|

Waehrens et al. [36] |

In creating plant-based cheese analogs, butyric acid fermentation could mimic traditional dairy cheese flavors, contributing to savory notes in the product. |

|

Liu et al. [37] |

Butyric acid is beneficial for gut health, and its controlled production in plant-based foods could enhance nutritional value despite controversy over its role in obesity. |

|

Kårlund et al. [38]; Gultekin et al. [39] |

Controlled butyric acid fermentation has biotechnological applications in developing plant-based food ingredients or additives, like flavor enhancers or preservatives. |

|

Liu et al. [37] |

While butyric acid is mainly known for its benefits in the human gut from dietary fibers, exploring its prebiotic or probiotic potential in plant-based foods is a potential area for future investigation. |

Table 2: Summary of the findings from various sources on the application of alcoholic, lactic acid, acetic acid, and butyric acid fermentation in plant-based foods.

Bread Making: Alcoholic fermentation is crucial in bread making [14,15]. Yeast ferments sugars present in flour, producing carbon dioxide gas, which causes the dough to rise. This process, known as leavening, forms air pockets in the bread, giving it a light and airy texture.

Sauerkraut and Kimchi Fermentation: In the preparation of fermented cabbage products like sauerkraut and kimchi, alcoholic fermentation occurs alongside lactic acid fermentation [16]. The sugars present in cabbage are first converted into alcohol by yeast and then into lactic acid by lactic acid bacteria. This dual fermentation process imparts the characteristic tangy flavor and enhances the shelf life of these fermented vegetables [17].

Sourdough Fermentation: Alcoholic fermentation is essential in creating sourdough bread. The wild yeast in the flour or introduced through a sourdough starter ferments the sugars, producing carbon dioxide and alcohol [18]. The carbon dioxide causes the dough to rise, while the alcohol contributes to the unique flavor profile of sourdough bread.

Fermented Beverages: Alcoholic fermentation produces various plant-based fermented beverages, such as ginger beer and kombucha [19]. In these beverages, yeast ferments the sugars in ingredients like ginger or sweetened tea, producing alcohol and carbonation.

Soy Sauce Production: Soy sauce, a staple condiment in many cuisines, undergoes a fermentation process that includes alcoholic fermentation [20]. Yeast and lactic acid bacteria contribute to the breakdown of complex compounds in soybeans, leading to the production of alcohol and the development of the sauce's rich umami flavor.

Lactic Acid Fermentation

In Lactic Acid fermentation, bacteria like Lactobacillus convert sugars into lactic acid. This process is responsible for the tangy flavors and preservation of foods like yogurt, cheese, and sauerkraut [40]. Lactic acid fermentation, a process as old as civilization itself, has garnered increasing attention in recent years for its diverse applications and profound impact on our health and culinary traditions. Greeks and Romans harnessed its transformative power to preserve vegetables, dairy products, and meats.

The fermentation process, which relies on lactic acid-producing bacteria like Lactobacillus and Streptococcus, not only prolongs the shelf life of foods but also imbues them with unique flavors and textures [41]. This time-honored tradition of fermenting foods laid the foundation for contemporary culinary foods such as sauerkraut, yogurt, and kimchi. Not only do these foods improve food taste, they also provide a myriad of health benefits. Probiotics, live microorganisms found in fermented foods, are known to promote gut health, boost immunity, and even enhance nutrient absorption. Lactic acid fermentation, therefore, plays a vital role in the symbiotic relationship between food and human well-being.

At its core, lactic acid fermentation is a metabolic pathway used by various microorganisms, primarily lactic acid bacteria, to convert carbohydrates into lactic acid. This metabolic transformation is anaerobic, meaning it occurs without oxygen. Lactobacillus species, for instance, ferment sugars to produce lactic acid, which acts as a natural preservative, lowering the pH of the environment and inhibiting the growth of harmful bacteria [42]. The scientific understanding of lactic acid fermentation has paved the way for controlled processes in the food industry, ensuring product safety and consistency.

In addition to its culinary and health advantages, lactic acid fermentation contributes to sustainability and food security [38]. Extending the shelf life of perishable foods reduces food waste and supports global efforts to combat hunger and malnutrition. Moreover, it is a natural alternative to chemical preservatives, aligning with the growing demand for clean and natural food products.

Biotechnology and microbial engineering advances are unlocking new possibilities, from developing novel fermented products to designing Lactic acid bacteria strains with specific functional properties. These innovations promise to create tailored probiotics, personalized nutrition, and sustainable food production systems [43].

Application of Lactic Acid in Plant-Based Foods

Lactic acid fermentation is a key process in producing various plant-based foods, contributing to flavor development, preservation, and enhancing nutritional properties. This fermentation type involves the conversion of sugars into lactic acid by lactic acid bacteria. Here are some applications of lactic acid fermentation in plant-based foods.

Fermented Vegetables: Lactic acid fermentation is widely used in the preparation of fermented vegetables such as pickles, sauerkraut, and kimchi. In these products, sugars present in the vegetables are converted into lactic acid by lactic acid bacteria, creating a tangy flavor and contributing to the preservation of the vegetables [16]. The acidity generated during fermentation also acts as a natural preservative, inhibiting the growth of harmful microorganisms.

Sourdough Bread: Lactic acid fermentation is crucial in sourdough bread making. Lactic acid bacteria in the sourdough starter or naturally occurring in the flour contribute to the breakdown of sugars, producing lactic acid [16]. This acidification not only enhances the flavor profile of the bread but also helps in the leavening process by creating an acidic environment conducive to yeast activity.

Plant-Based Yogurts: Plant-based yogurts often involve lactic acid fermentation. Microorganisms like Lactobacillus bulgaricus and Streptococcus thermophilus convert sugars in plant-based milk alternatives (almond, soy, or coconut milk) into lactic acid [21]. This imparts a characteristic tanginess to the yogurt and gives it a creamy texture.

Fermented Beverages: Lactic acid fermentation produces various fermented beverages, including plant-based options like kefir and certain fruit juices [16]. In kefir, for example, lactic acid bacteria contribute to the fermentation process and the generation of a tangy flavor profile.

Tempeh Production: Tempeh, a traditional Indonesian fermented food product from soybeans, involves lactic acid fermentation [22]. In this process, Rhizopus molds ferment the soybeans, producing lactic acid, among other compounds. The resulting product has a unique texture, flavor, and enhanced nutritional profile.

Fermented Plant-Based Protein: Lactic acid fermentation is explored in developing fermented plant-based protein products [23]. Fermentation can improve the digestibility of plant proteins, reduce anti-nutritional factors, and enhance the overall nutritional quality of the final product.

Enhanced Nutrient Bioavailability: Lactic acid fermentation can increase the bioavailability of certain nutrients in plant-based foods. Fermentation breaks down compounds like phytates, making minerals more accessible for absorption. This can improve nutritional value [24].

Acetic Acid Fermentation

Acetobacter bacteria transform alcohol into acetic acid, giving rise to the timeless art of acetic acid fermentation, commonly associated with vinegar production. This ancient process, dating back thousands of years, holds historical significance and culinary allure. Acetic acid bacteria, particularly Acetobacter species, orchestrate the two-step oxidation process, converting ethanol into acetic acid, resulting in the tangy and flavorful liquid we know as vinegar. Beyond its culinary use, vinegar has potential health benefits. It serves dual purposes as both a kitchen staple and an eco-friendly household cleaner, aligning with sustainability efforts. Advancements in biotechnology and microbiology continue to shape acetic acid fermentation, paving the way for new flavors and applications in biotechnology, biofuels [44], and pharmaceuticals [45], showcasing the enduring relevance of this microbial transformation.

Applications of Acetic Acid Fermentation in Plant-Based Foods

Vinegar Production: The most well-known application of acetic acid fermentation is vinegar production [25]. This acidic liquid is often derived from plant-based sources such as apples, grapes, or grains. Acetic acid bacteria, particularly Acetobacter species, convert ethanol into acetic acid, giving vinegar its characteristic tangy flavor. Vinegar is used not only as a condiment but also as a preservative and flavor enhancer in various culinary applications.

Fermented Pickles: Acetic acid fermentation is commonly employed to prepare fermented pickles. Vegetables like cucumbers are submerged in a brine solution where acetic acid bacteria convert sugars into acetic acid. The resulting pickles have a sour and tangy taste, and the acidic environment created by acetic acid helps preserve the vegetables.

Kombucha: Kombucha, a popular fermented beverage, undergoes acetic acid fermentation alongside other fermentation processes [25]. Acetic acid bacteria convert sugars from tea and other flavoring agents into acetic acid, giving kombucha its characteristic sourness. The acidity also acts as a preservative and contributes to the unique taste profile of this beverage.

Fermented Condiments: Acetic acid fermentation produces various fermented condiments, such as hot sauces and mustard [25]. Peppers, fruits, or mustard seeds are fermented with acetic acid bacteria, contributing to the preservation of the condiments and the development of complex flavors.

Fermented Grains: Acetic acid fermentation can be involved in the fermentation of plant-based grains [25]. For example, in the fermentation of rice to produce rice vinegar or the fermentation of grains for the production of certain traditional fermented foods, acetic acid bacteria play a role in the transformation of sugars into acetic acid.

Enhanced Food Safety: The acidic environment created by acetic acid fermentation helps enhance plant-based foods' safety by inhibiting pathogenic bacteria growth [26]. This natural preservative effect contributes to the extended shelf life of fermented products.

Improved Digestibility: Acetic acid fermentation can contribute to improved digestibility and bioavailability of nutrients in plant-based foods [27].

Propionic Acid Fermentation

Propionic acid fermentation, a key process in iconic cheeses like Swiss and Emmental, has historical roots in European cheese-making traditions. Propionibacterium species, notably P. freudenreichii, drive this microbial transformation, creating characteristic holes and contributing to the cheese's unique flavor [46]. Next to its culinary role, propionic acid fermentation has industrial applications, producing preservatives and mold inhibitors [47]. Studies also suggest potential health benefits, with propionic acid showing anti-inflammatory and immune-modulating properties. P. freudenreichii, recognized for its probiotic potential, highlights the fermentation's multifaceted role in both culinary and health realms, paving the way for future innovations in cheese-making and well-being [48].

Applications of Propionic Acid Fermentation in Plant-Based Foods

Swiss Cheese Analogs: In the plant-based food industry, efforts are made to replicate the characteristics of dairy-based products. Though not as common in plant-based cheeses, propionic acid fermentation might be employed in producing Swiss cheese analogs [28]. Fermentation of plant-based milk alternatives with specific bacterial strains could mimic the nutty and slightly sweet flavor of traditional Swiss cheese.

Use as a Preservative: Propionic acid and its salts (calcium propionate and sodium propionate) are recognized as food preservatives. It inhibits the growth of molds and certain bacteria, contributing to the extended shelf life of food products. In some plant-based baked goods or snacks, propionic acid or its salts prevent spoilage and maintain product quality [29].

Bioprocessing of Plant-Based Ingredients: Propionic acid fermentation processes may be explored in bioprocessing plant-based raw materials [30]. This could involve the utilization of specific bacteria capable of producing propionic acid during the fermentation of plant-derived sugars or other substrates [31]. The resulting fermentation by-products could influence the flavor and preservation of the final product.

Fermented Plant-Based Protein Products: Propionic acid fermentation might be considered in developing fermented plant-based protein products [32]. The fermentation process could enhance the organoleptic qualities of the protein and potentially contribute to the development of unique flavors in these products.

Biotechnological Applications: When applied and controlled, propionic acid fermentation has biotechnological applications. This includes potential use in developing plant-based food ingredients or additives that provide specific flavors or functional properties [33].

Butyric Acid Fermentation

Butyric acid fermentation, often overlooked, is gaining prominence for its pivotal role in gut health and beyond [49]. Certain bacteria, like Clostridium and gut microbiota species, produce butyric acid as they break down dietary fiber and resistant starch. This short-chain fatty acid is a crucial energy source for colon cells. It offers health benefits, including anti-inflammatory and immunomodulatory properties. Recent research links butyrate to metabolic health, insulin sensitivity, and potential therapeutic applications beyond the gut. Diet, particularly fiber-rich, influences butyric acid fermentation, opening avenues for therapeutic interventions and revolutionizing our approach to gut health and overall well-being [49].

Potential Roles of Butyric Acid Fermentation in Plant-Based Foods

Butyric Acid as a Flavor Component: Butyric acid contributes a characteristic buttery aroma and taste [34]. In plant-based foods, particularly those aiming to replicate dairy flavors, the controlled fermentation leading to butyric acid production may be explored to enhance the overall flavor profile.

Use in Fermented Plant-Based Milk: Butyric acid fermentation could produce fermented plant-based milk alternatives [35]. While lactic acid fermentation is more common, including butyric acid-producing bacteria might offer a unique flavor profile and potentially contribute to developing a richer and more complex taste.

Potential in Fermented Plant-Based Cheeses: In creating plant-based cheese analogs, butyric acid fermentation might be considered to mimic the flavors associated with traditional dairy-based cheeses [36]. Butyric acid production can contribute to developing nuanced and savory notes in the final product.

Role in Gut Health: Butyric acid is known for its potential health benefits, especially in promoting gut health; however, the role of butyrate in obesity remains controversial [37]. While its concentration might be relatively low in plant-based foods, the controlled fermentation leading to butyric acid production could contribute to these products' overall nutritional value.

Biotechnological Applications: The controlled fermentation processes leading to butyric acid production could have broader biotechnological applications in developing plant-based food ingredients or additives. These could include flavor enhancers, preservatives, or nutritional improvements [38,39].

Prebiotic and Probiotic Potential: Butyric acid is beneficial for gut health [37]. While it is often associated with the fermentation of dietary fibers in the human colon rather than in food processing, exploring its potential as a prebiotic or probiotic in plant-based foods could be an area for future investigation.

Discussion

Fermentation technology drives the development of non-animal-based meats, dairy, and protein-rich sustainable food sources in substitute, replacement, and analogs (Table 1). These innovative products aim to replicate the sensory experience and nutritional value of traditional animal-based foods. They offer consumers various choices that align with their dietary preferences and values. Fermentation is the linchpin that enables these products to transform the food industry by bridging the gap between traditional and alternative food options.

Fermentation in non-animal-based foods has far-reaching implications beyond product development, impacting food sustainability, the environment, and the health and well-being of consumers. Some key aspects are discussed below.

Sustainability: Fermentation processes are pivotal in promoting sustainability through resource efficiency and waste reduction. Microorganisms employed in fermentation can efficiently convert plant-based raw materials into valuable products, minimizing the environmental footprint of food production. Additionally, fermentation can utilize by-products and waste streams from various industries as substrates, contributing to a circular and sustainable food system by reducing overall waste [38,50].

Environmental Impact: Fermentation processes offer environmental benefits by reducing greenhouse gas emissions compared to certain traditional agricultural practices [51]. The shift towards plant-based fermentation further contributes to lower carbon footprints associated with livestock farming. Additionally, fermentation-based alternative foods generally require less land and water, addressing deforestation, habitat destruction, and water scarcity concerns.

Health and Well-being: Fermentation introduces beneficial microorganisms into foods, offering potential health benefits such as improved gut health, enhanced immune function, and overall well-being. Producing probiotics, prebiotics, and bioactive compounds during fermentation enhances health outcomes. Fermented alternatives can also provide solutions for individuals with food allergies by reducing allergenic proteins in certain foods [37,49].

Diversity in Diets: The versatility of fermentation enables the creation of a wide variety of plant-based alternatives, catering to diverse dietary preferences and restrictions. This promotes dietary diversity and inclusivity, creating a more sustainable and varied food landscape [14,23].

Innovation in Product Development: Fermentation fosters innovation in product development by allowing the creation of unique flavors, textures, and aromas in alternative foods. This culinary diversity enhances the sensory experience of plant-based and fermented products, making them more appealing to consumers and driving innovation in the food industry [5,23].

Economic Impact: The rise of fermented alternative foods has spurred the development of a growing market segment, presenting economic opportunities for producers. This growth contributes to job creation and stimulates innovation within the food industry, fostering economic development. Food fermentation represents a significant economic opportunity for women and the marginalized [52].

Global Food Security: Fermentation can harness various protein sources, such as microbial or fungi-based proteins, which are more resource-efficient than traditional meat production. This diversification of protein sources contributes to global food security by ensuring efficient and sustainable protein production [52,53].

Biodiversity Conservation: Shifting towards plant-based and fermentation-derived options helps conserve biodiversity by reducing the pressure on ecosystems [54]. This reduction in demand for agricultural land mitigates the environmental impact associated with intensive livestock farming, contributing to the conservation of ecosystems and biodiversity.

Implementation Challenges

However, scaling up fermentation processes from laboratory or pilot-scale to industrial production poses various challenges that need careful consideration. Successfully navigating pilot fermentations demands a profound understanding of the organism's biology and the requisite equipment. It is crucial to grasp the system's physical and chemical constraints and devise strategies to overcome scaling-up obstacles. Choosing an appropriate bioreactor ensures success and maximizes product yield, quality, and stability [55].

For example, maintaining consistency in fermentation processes presents a substantial challenge when scaling up production. Precise control of nutrient availability, temperature, pH, and oxygen levels is essential to replicate successful conditions observed at smaller scales [41]. Consistent product quality on a larger scale demands meticulous attention to these variables. Also, effective heat transfer and temperature control have become increasingly challenging in larger fermentation vessels [56]. Thermodynamics, defined as "the force of heat," is intricately connected to microbial growth's observable heat dissipation process. Exploring the thermodynamics of microbial growth involves studying why growing microbial cultures produce and dissipate heat, including the quantification of Gibbs energy. Efficient heat dissipation is vital in preventing temperature spikes that could adversely affect the growth and metabolism of microorganisms, making optimizing heat transfer mechanisms crucial for successful large-scale fermentation [57,58].

Furthermore, oxygen transfer poses another hurdle as production scales up [59]. Adequate aeration is vital for aerobic fermentations, and ensuring uniform oxygen distribution throughout the larger fermentation vessel becomes a critical concern. Maintaining optimal oxygen levels becomes more complex as the scale of fermentation increases [59,60]. Sterilization poses a more significant challenge in larger vessels and associated equipment. The effective sterilization of the entire system without compromising equipment integrity is crucial to prevent contamination [61]. Addressing these challenges is paramount to maintaining the integrity of the fermentation process.

Additional technological challenges must be addressed in large-scale fermentation processes. These challenges include managing foam formation [62], addressing variations in the growth characteristics of microbial cultures, and implementing effective monitoring and control systems for the fermentation process on a larger scale [63]. Furthermore, downstream processing becomes a significant consideration in large-scale fermentation, requiring substantial efforts to isolate and purify the desired product efficiently [62].

Finally, economic considerations emerge as fermentation processes scale up [64,65]. Larger vessels and increased resource requirements impact the overall cost of production. Balancing the benefits of increased output with associated costs becomes essential to ensure economic viability. Also, the environmental impact of fermentation processes becomes more pronounced at larger scales, encompassing aspects such as energy and resource consumption, waste generation, and overall sustainability. Implementing environmentally friendly practices is a growing concern in pursuing sustainable large-scale fermentation processes.

Addressing these challenges requires a combination of engineering, biotechnology, and process optimization. Collaboration between scientists, engineers, and industry experts is essential to overcome these obstacles and successfully implement large-scale fermentation processes for industrial production.

Conclusion and the Future Outlook

The future outlook for fermentation in alternative foods is marked by exciting prospects and potential limitations that shape the trajectory of this innovative field. With ongoing technological advancements in biotechnology and genetic engineering, the landscape of alternative foods is poised to diversify significantly. The potential for diverse product offerings, including plant-based meats, dairy alternatives, and functional snacks, presents an enticing array of choices for consumers with varying dietary preferences. As fermentation processes become more efficient and scalable, cost reductions are possible, making alternative foods more accessible to a broader audience.

One exciting prospect lies in creating functional and nutrient-rich foods through fermentation. Innovations may lead to products beyond traditional flavors, incorporating bioactive compounds for enhanced nutritional value. Developing sustainable protein sources derived from fungi, algae, and microbial fermentation holds promise in addressing environmental concerns associated with conventional meat production. Precision fermentation, involving genetic engineering for specific compound creation, opens avenues for highly tailored and customizable foods, potentially leading to personalized nutrition options.

However, amid these exciting prospects, potential limitations also loom on the horizon. Regulatory challenges in establishing clear guidelines for fermented alternative foods may arise as authorities strive to balance innovation with consumer safety. Overcoming public perception and acceptance barriers, including taste and texture preferences, will be crucial for widespread adoption. Scaling up production to meet mass-market demands presents engineering challenges, requiring solutions for consistency, efficiency, and cost-effectiveness at larger scales. Economic viability and competitiveness with traditional options, as well as socio-cultural factors and ethical considerations associated with advanced technologies, also challenge the seamless integration of fermented alternative foods into mainstream markets.

In navigating the future of fermentation in alternative foods, collaboration between scientists, industry stakeholders, regulators, and consumers becomes paramount. Overcoming these challenges will not only foster innovation but also contribute to the realization of a sustainable and diverse food future.

Conflicts of Interest

The authors declare no conflicts of interest.

Data Availability

Not Applicable

References

- Abbaspour N, Sanchez R, Sabaté J (2023) Non-animal-based options for animal-based foods- towards a systematic terminology. Frontiers in Nutrition 10:

- Samtiya M, Aluko RE, Puniya AK, Dhewa T (2021) Enhancing micronutrients bioavailability through fermentation of plant-based foods: A concise review. Fermentation 7:

- World Economic Forum (2019) Meat: The future. A Roadmap for Delivering 21st-Century Protein. World Economic Forum ,Cologny, Switzerland.

- Ramírez Rojas AA, Swidah R, Schindler D (2022) Microbes of traditional fermentation processes as synthetic biology chassis to tackle future food challenges. Frontiers in. Bioengineering and Biotechnology 10:

- Teng TS, Chin YL, Chai KF, Chen WN (2021) Fermentation for future food systems: Precision fermentation can complement the scope and applications of traditional fermentation. EMBO Reports 22:

- Taveira IC, Nogueira KMV, Oliveira DLG, Silva RDN (2021) Fermentation: Humanity's oldest biotechnological tool. Frontiers for Young Minds 9:

- Dunn J, Grider MH (2023) Physiology, adenosine triphosphate. StatPearls Publishing, Florida, United States.

- Eldarov MA, Avdanina DA, Ivanova E, Shalamitskiy MY, Tanashchuk TN, et al. (2021) Stress resistance and adhesive properties of commercial flor and wine strains and environmental isolates of Saccharomyces cerevisiae. Fermentation 7:

- Maicas S (2021) Advances in wine fermentation. Fermentation 7:

- Raihofer L, Zarnow M, Gastl M, Hutzler M (2022) A short history of beer brewing: Alcoholic fermentation and yeast technology over time. EMBO Reports 23: 56355.

- Timmermans E, Bautil A, Brijs K, Scheirlinck I, der Meulen RV, et al. (2022) Sugar levels determine fermentation dynamics during yeast pastry making and its impact on dough and product characteristics. Foods 11:

- Muñoz-Redondo JM, Puertas B, Pereira-Caro G, Ordoñez-Díaz JL, Ruiz-Moreno MJ, et al. (2021) A statistical workflow to evaluate the modulation of wine metabolome and its contribution to the sensory attributes. Fermentation 7:

- Prado MR, Blandón LM, Vandenberghe LP, Rodrigues C, Castro GR, et al. (2015) Milk kefir: Composition, microbial cultures, biological activities, and related products. Frontiers in Microbiology 6: 1177.

- Siddiqui SA, Erol Z, Rugji J, Tasçi F, Kahraman HA, et al. (2023) An overview of fermentation in the food industry - looking back from a new perspective. Bioresources and Bioprocessing 10:

- Maicas S (2020) The role of yeasts in fermentation processes. Microorganisms 8:

- Dimidi E, Cox SR, Rossi M, Whelan K (2019) Fermented foods: Definitions and characteristics, impact on the gut microbiota and effects on gastrointestinal health and disease. Nutrients 11:

- Satora P, Skotniczny M, Strnad S, Ženišová K (2020) Yeast microbiota during sauerkraut fermentation and Its characteristics. International Journal of Molecular Sciences 21:

- Sofo A, Galluzzi A, Zito F (2021) A modest suggestion: Baking using sourdough - a sustainable, slow-paced, traditional and beneficial remedy against stress during the Covid-19 lockdown. Human Ecology 49: 99-105.

- Chong AQ, Lau SW, Chin NL, Talib RA, Basha RK (2023) Fermented beverage benefits: A comprehensive review and comparison of kombucha and kefir microbiome. Microorganisms 11:

- Devanthi PVP, Gkatzionis K (2019) Soy sauce fermentation: Microorganisms, aroma formation, and process modification. Food Research International 120: 364-374.

- Montemurro M, Pontonio E, Coda R, Rizzello CG (2021) Plant-based alternatives to yogurt: State-of-the-art and perspectives of new biotechnological challenges. Foods 10:

- Romulo A, Surya R (2021) Tempe: A traditional fermented food of Indonesia and its health benefits. International Journal of Gastronomy and Food Science 26: 100413.

- Boukid F, Hassoun A, Zouari A, Tülbek MÇ, Mefleh M, et al. (2023) Fermentation for designing innovative plant-based meat and dairy alternatives. Foods 12:

- Knez E, Kadac-Czapska K, Grembecka M (2023) Effect of fermentation on the nutritional quality of the selected vegetables and legumes and their health effects. Life 13: 655.

- Hata NNY, Surek M, Sartori D, Serrato RV, Spinosa WA (2023) Role of acetic acid bacteria in food and beverages. Food Technology & Biotechnology 61: 85-103.

- Leeuwendaal NK, Stanton C, O'Toole PW, Beresford TP (2022) Fermented foods, health and the gut microbiome. Nutrients 14:

- Nkhata SG, Ayua E, Kamau EH, Shingiro JB (2018) Fermentation and germination improve nutritional value of cereals and legumes through activation of endogenous enzymes. Food Science & Nutrition 6: 2446-2458.

- Genet BML, Molina GES, Wätjen AP, Barone G, Albersten K, et al. (2023) Hybrid cheeses-supplementation of cheese with plant-based ingredients for a tasty, nutritious and sustainable food transition. Fermentation 9:

- Tangyu M, Muller J, Bolten CJ, Wittmann C (2019) Fermentation of plant-based milk alternatives for improved flavour and nutritional value. Applied Microbiology and Biotechnology 103: 9263-9275.

- Gonzalez-Garcia RA, McCubbin T, Navone L, Stowers C, Nielsen LK, et al. (2017) Microbial propionic acid production. Fermentation 3:

- Ranaei V, Pilevar Z, Khaneghah AM, Hosseini H (2020) Propionic acid: Method of production, current state and perspectives. Food Technology and Biotechnology 58: 115-127.

- Illikoud N, do Carmo FLR, Daniel N, Jan G, Gagnaire V (2023) Development of innovative fermented products by exploiting the diversity of immunomodulatory properties and fermentative activity of lactic and propionic acid bacteria. Food Research International 166:

- Elhalis H, See XY, Osen R, Chin XH, Chow Y (2023) Significance of fermentation in plant-based meat analogs: A critical review of nutrition, and safety-related aspects. Foods 12:

- Stanzer D, Cica KH, Blesic M, Murtic MS, Mrvcic J, et al. (2023) Alcoholic fermentation as a source of congeners in fruit spirits. Foods 12:

- Horlacher N, Oey I, Agyei D (2023) Learning from tradition: Health-promoting potential of traditional lactic acid fermentation to drive innovation in fermented plant-based dairy alternatives. Fermentation 9:

- Waehrens SS, Faber I, Gunn L, Buldo P, Frøst MB, et al. (2023) Consumers' sensory-based cognitions of currently available and ideal plant-based food alternatives: A survey in Western, Central and Northern Europe. Food Quality and Preference 108:

- Liu H, Wang J, He T, Becker S, Zhang G, et al. (2018) Butyrate: A double-edged sword for health? Advances in Nutrition 9: 21-29.

- Kårlund A, Gómez-Gallego C, Korhonen J, Palo-Oja OM, El-Nezami H, et al. (2020) Harnessing microbes for sustainable development: Food fermentation as a tool for improving the nutritional quality of alternative protein sources. Nutrients 12:

- Gultekin F, Oner ME, Savas HB, Dogan B (2020) Food additives and microbiota. Northern Clinics of Istanbul 7: 192-200.

- Hoffstater L (2023) Fermentation: Unleashing the power of microbes for flavour and preservation. Farmacologiay Toxicologia 3: 001-003.

- Voidarou C, Antoniadou Μ, Rozos G, Tzora A, Skoufos I, et al. (2021) Fermentative foods: Microbiology, biochemistry, potential human health benefits and public health issues. Foods 10:

- Abedi E, Hashemi SMB (2020) Lactic acid production - producing microorganisms and substrates sources-state of art. Heliyon 6:

- Augustin MA, Hartley CJ, Maloney G, Tyndall S (2023) Innovation in precision fermentation for food ingredients. Critical Reviews in Food Science and Nutrition

- Budsberg E, Morales-Vera R, Crawford JT, Bura R, Gustafson R (2020) Production routes to bio-acetic acid: life cycle assessment. Biotechnology for Biofuels and Bioproducts 13:

- Mousavi SM, Hashemi SA, Zarei M, Gholami A, Lai CW, et al. (2020) Recent progress in chemical composition, production, and pharmaceutical effects of Kombucha Beverage: A Complementary and alternative medicine. Evidence-Based Complementary and Alternative Medicine

- Zheng X, Shi X, Wang B (2021) A Review on the general cheese processing technology, flavor biochemical pathways and the influence of yeasts in cheese. Frontiers in Microbiology 12:

- Antone U, Ciprovica I, Zolovs M, Scerbaka R, Liepins J (2023) Propionic acid fermentation-study of substrates, strains, and antimicrobial properties. Fermentation 9:

- Jeantet R, Jan G (2021) Improving the drying of Propionibacterium freudenreichii starter cultures. Applied Microbiology and Biotechnology 105: 3485-3494.

- Li Y, Faden HS, Zhu L (2020) The Response of the gut microbiota to dietary changes in the first two years of life. Frontiers in Pharmacology 11: 334.

- Saadoun JH, Bertani G, Levante A, Vezzosi F, Ricci A, et al. (2021) Fermentation of agri-food waste: A promising route for the production of aroma compounds. Foods 10: 707.

- Agrawal D, Awani K, Nabavi SA, Balan V, Jin M, et al. (2023) Carbon emissions and decarbonisation: The role and relevance of fermentation industry in chemical sector. Chemical Engineering Journal 475:

- Materia VC, Linnemann AR, Smid EJ, Schoustra SE (2021) Contribution of traditional fermented foods to food systems transformation: Value addition and inclusive entrepreneurship. Food Security 13: 1163-1177.

- Misci C, Taskin E, Dall'Asta M, Fontanella MC, Bandini F, et al. (2021) Fermentation as a tool for increasing food security and nutritional quality of indigenous African leafy vegetables: The case of Cucurbita Food Microbiology 99: 103820.

- Kozicka M, Havlík P, Valin H, Wollenberg E, Deppermann A, Net al. (2023) Feeding climate and biodiversity goals with novel plant-based meat and milk alternatives. Nature Communication 14:

- Crater JS, Lievense JC (2018) Scale-up of industrial microbial processes. FEMS Microbiol Lett 365:

- Zenteno MI, Pérez-Correa JR, Gelmi CA, Agosin E (2010) Modeling temperature gradients in wine fermentation tanks. Journal of Food Engineering 99: 40-48.

- Frank SA (2020) Metabolic heat in microbial conflict and cooperation. Preprints

- Quéméner EDL, Bouchez T (2014) Thermodynamic theory of microbial growth. ISME J 8: 1747-1751.

- Noorman HJ, Winden WV, Heijnen JJ, Lans RGJM (2018) Intensified fermentation processes and equipment. Royal Society of Chemistry, London, UK.

- Hanspal N, Chai N, Allen B, Brown D (2020) Applying multiple approaches to deepen understanding of mixing and mass transfer in large-scale aerobic fermentations. Journal of Industrial Microbiology Biotechnology 47: 929-946.

- Singh V, Haque S, Niwas R, Srivastava A, Pasupuleti M, et al. (2017) Strategies for fermentation medium optimization: An in-depth review. Frontiers in Microbiology 7: 2087

- Deotale SM, Dutta S, Moses JA, Anandharamakrishnan C (2023) Foaming and defoaming-concepts and their significance in food and allied industries: A review. Discover Chemical Engineering3:

- Sharma R, Garg P, Kumar P, Bhatia SK, Kulshrestha S (2020) Microbial fermentation and its role in quality improvement of fermented foods. Fermentation 6:

- Zilberman D, Kim E (2011) The lessons of fermentation for the new bio-economy. AgBioForum 14: 97-103.

- Dutta A, Dowe N, Ibsen KN, Schell DJ, Aden A (2010) An economic comparison of different fermentation configurations to convert corn stover to ethanol using Z. mobilis and Saccharomyces. Biotechnology Progress 26: 64-72.

Citation: Abbaspour N (2024) Recent Progress in the Role of Fermentation in Plant-Based Foods: A Concise Review. J Food Sci Nutr 10: 175.

Copyright: © 2024 Nazanin Abbaspour, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.