Source, Extraction and Constituents of Fats and Oils

*Corresponding Author(s):

Ogori AFDepartment Of Home Science, Faculty Of Agriculture, Federal University, Gashua, P.M.B.1005 Gashua, Yobe State, Nigeria; Department Of Food Science And Technology, Federal University Of Agriculture, P.M.B. 2373, Makurdi, Benue State, Nigeria

Tel:+234 08070626328,

Email:ogoriakamafriday@gmail.com

Abstract

Fat and oil are critical for human nutrition, as a major source of energy and with numerous functionalities in biochemical pools become imperative to review it source method of extraction and chemical composition. Fat and oil are majorly sourced from plant and animal. Traditional and modern methods of extraction as well as refining were reviewed. Triglyceride phospholipids, sterol, pigments, fatty alcohols and tocopherol are some of the chemical constituent that defines the molecular and biochemical configuration of source oils and fats.

Keywords

Application; Chemical; Fat; Food; Oil; Source

INTRODUCTION

Fats are triglycerides that are solid or semi-solid at room temperature, oil are also triglycerides that are liquid or clear liquid at room temperature, however their chemistry is determined by the degree of solubility. Fat and oil makes the major three classes of food after carbohydrate and proteins. They are good source of nutrient and could supply about (9 kcalories) of energy in a metabolicpool. The functional unit of fat and oil are triglycerides derived from fatty acid (3 units) and glycerol (1 unit), however fat and oil does have other polymeric structures such as monomers, dimers and trimmers derived from free fatty acids, sterol, phospholipids, tocopherol, pigments and lipoproteins moieties Potter and Hotchkis [1]. Because of their structural positioning from fatty acid group, they are grouped as saturated, monosaturated or polyunsaturated [2]. Plant sources are major polyunsaturated sources and saturated, majorly from animal origin. Major fatty acid s includes palmatic, oleic, stearic, lauric, linoleic acid. The roles of fat and oil in the body or food systems through fatty acid mediations or reconfiguration through processing includes hormonal effects, regulation of body systems, protection of delicate organs, carries of soluble vitamins, sensory palatability, satiation mechanisms and posing cholesterol density such as LDL and HDL in cells. Fat and oil enhances aeration, moisture retention, effective cooking in frying and other functional and physiochemical attributes in food and food systems.

SOURCES OF FATS AND OILS

Fats and oil may be of vegetable, animal and marine origin. Vegetable fats include the solid fat cocoa batter and the oils such as corn oil, sun flower oil, soybean oil, cotton soil, peanut oil, olive oil, canola oil, pumpkin seed oil, safflower oil, grape seed oil, sesame oil bran oil, argan oil, palm oil, linseed oil, coconut oil.

Typically common vegetable oils including soybean. Sunflower, safflower, mustard, olive, rice bran, sesame are low in saturated fats. While palm oil, palm kernel oil, coconut oil, tallow and butter fat are high in saturated fats [3].

Animal fats include lard tallow and butterfat while fish oils include cod liver oil, whale oil and salmon oil.

Animal fats

Butterfat: This is usually obtained from cow's milk. It is a mixture of butterfat, water and salt. Butter list is an important source of vitamin A and to be lesser extent of vitamin D. It comprised of 29-32% monounsaturated, 2-4% polyunsaturated and (12-32%) saturated fatty acids [4]. Its distinct flavor and yellow colour are important factors in its popularity. It is used as a table spread has decreased while increasing the use of margarine because of lower price, improves and uniform quality and health Factors. Butterfat is a part of many other dairy products such as milk, cheese, ice cream, coffee cream and whipping cream.

Lard: Lard is a fat rendered from the fatty tissues of pig. Lard is composed of 46.2% saturated fatty acids. 45.2% monounsaturated fatty acids. 11.0% polyunsaturated fatty acids.

Tallow: Edible tallow is obtained primarily from beef cattle. At room temperature, it is harder and firmer than lard. Tallow comprises of 54.9% saturated fully acids. 40.9% unsaturated fatty acids. 4.2% polyunsaturated fatty acids.

Fish oils

Fish oils can be obtained li'on1 the bodies or livers of several fish including cod fish. Whale, salmon. etc. Fatty acid composition varies not only from species to species, hut often to an even greater extent from one fish to another of the same species.

Cod liver oil: This is derived from liver of cod fish. As with most fish oils, it has high levels of the omega-3 fatty acids. Eicosapentaenoic Acid (EPA) and Docosahexaenoic Acid (DHA). Cod liver oil also contains vitamin A and vitamin D.

Vegetable oils

Soybean oil: This is obtained from the seed of the soybean plant. It is the oil produced in largest quantity. It is the dominant edible oil in the United States. It is composed of 61% polyunsaturated fatty acids, 25% monounsaturated fatty acid and 15% saturated linty acids [5]. The essential fatty acids linolenic and α-linolenic acids account for 89 and 11% of the total essential fatty acids from this source. About 48% of soybean oil is used in margarine, shortening, cooking and salad oils, mayonnaise. These are both of dietary importance but are also the cause of oxidative instability of this oil.

Constituents and application of soured fat and oil from plants and animals in food systems

Palm oil: This is produced from the fruits of palm trees. lt is the most efficient oil-producing plant. It now takes second place in the list of oils produced worldwide. Palm oil has been balanced fatty acid composition in which the level of saturated fatty acids is almost equal to that of the unsaturated fatty acids. Palmitic acid (44-45%) and oleic acid (39-40%) are the major component acids along with linoleic acid (IU-l l%) and only a trace amount of linolcnic acid [6].

The low level of linolcic acid and virtual absence of linolenic acid make the oil relatively stable to oxidative deterioration. Depending on the oil palm variet, some palm oils may appear to be more unsaturated. The dark red-orange colored palm oil is high in concentrations of carotenoids and anthocyanins. It is also high in vitamin E, present as tocopherols and tocotrienols. Almost 90% of palm oil is used as edible products in many.

Application: Applications such as cooking/frying oils, margarincs. shortenings, speciality tins and spray dried products.

Canola oil: This is edible oil obtained from it relatively new variety of rape seed plant. lt occupies the third position in order of production of oils and fats. Canola oil has a low level of saturated fatty acids (about 6%). Making it the second most important source of vegetable oil. The stability ol'tl1is oil is limited mostly by the presence of linolenic acid, chlorophyll and its decomposition products rind other minor components with high chemical reactivity. lt is high in tocopherol.

Application: lt is used majorly us shortening, margarine cooking and frying tilts.

Sun flower oil: lt is the Fourth of the most popular vegetable oils and in some countries; it is preferred to soybean. cotton seed and palm oils. Rut it is grown in limited geographical locations. It has u total saturated fat content less than 10%. 55-75% olcie acid and I5-35% linoleic acid.

Application: lt is excellent for cooking, making salad dressing, margaririne but not for frying due to its poor oxidation stability. Lt has good flavor stability.

Coconut oil: This is obtained from copra, which is dried coconut meat from the coconut palm known as Cocos nucifera. It is classified as a fat because it is solid at room temperature, but it does become liquid oil above 25.60C. lt is characterized by n high percentage of liquid acid. It contains 50% lauric acid while no other oil contains more than 1% except palm kernel oil. Due to its high level of saturated fatty acids (80%). Coconut oil is quite resistant to oxidative changes under normal storage conditions. lt has a tendency to cause a foaming problem due to its very low molecular weight; therefore does not mix comfortably with other oils.

Note: Mixing fats and oil with considerable differences in molecular weight tends to increase the possibility of foaming.

Applications: As frying oils with the production of margarine as milk fat substitute in filled milk (evaporated milk), as non-dairy creamers, in the production of infant and sports foods due to their medium chain triglycerides (easy digestion and absorption).

Palm kernel oil: This is also at lauric oil, second to coconut oil in the international market. lt is obtained from the kernel of oil palm tree, Elaeis guineensis. The fatty acid composition and properties of palm kernel oil are very similar to those of coconut oil, but it has a little lower shorter chain fatty acids and higher instauration. The major fatty acids in palm kernel oil are 48% lauric acid. 16% myristic acid und 15% oleic acid. No other fatty acid is present at more than 10%.

Application Its application is in the production of margarine, as frying oil (for shallow frying), filling creams (for biscuits, waters), in the production of non-dairy ice-creams, non-dairy whipping creams.

Cotton seed oil: This oil is obtained from the seed of the cotton plant. The oil is a by-product and is dependent on the use of cotton in textiles therefore the oil is traded only to at small extent. Crude cotton seed oil has u strong flavor und odour and a dark reddish brown colour. However, cotton seed oil cannot be processed to have as high oxidative and flavor stability.

Application .It is used in the preparation of some shortening, margarine, as a salad oil and for deep-frying some snack items.

Groundnut (peanut) oil: Groundnut oil is expressed from the seed of Arachis hypogaea commonly known us peanut, earthnut, and groundnut. Groundnut oil has it high content of digestible protein and is unsaturated with a roasted nutty flavor. The crude oil is pale yellow und is primarily used for deep frying and us cooking oil.

Application: In the preparation of shortenings, margarines and mayonnaise. Peanut oil is highly unsaturated and is therefore prone to rancidity. It contains a high proportion of oleic. linoleic and palmitic acid.

Olive oil: Virgin olive oil is obtained from the fruits of the olive tree. It is a mixture of triacylglycerol, with some lice fatty acids, majorly palmitic, palmitoleic, oleic and linoleie acids. lt contains about 71% oleic acid, unsaturated oil, virgin olive oil is oil that has not been dcodorized to remove natural olive oil flavor elements winch are considered to be desirable by the consumers.

Corn oil: Unlike most other vegetable oils corn oil (maize oil) is obtained from seeds kernels of maize. lt contains only 3-5% oil. Corn germ is rich in oil (greater than 30%) and is the source of all commercial corn oil. Corn oil has a pleasing flavor, relatively low levels (less than 15%) of saturated fatty acids. Very low levels a-linolenic acid and high levels of polyunsaturated fatty acids. Most of the corn oil produced is a by-product of corn starch production.

Application: The primary use of this oil is in corn margarines, cooking/salad oil.

Sesame seed oil: This is obtained from sesame seed, which has high oil content (42-56%). It is highly resistant to oxidation and displays several medicinal effects. Sesame seed oil is classier as a polyunsaturated oil with about 82% unsaturated fatty acid with approximately equal amounts of oleic and linoleic acids in the oil. Compared with other vegetable oil, sesame oil is highly resistant to oxidative deterioration.

Application: It is used as cooking oil.

Rice brain oil: Rice-brain oil is a by-product of rice milling and has been used for centuries in many south East Asian countries. Rice bran oil comprises about 20% saturated fatty acids and an even balance of monounsaturated and polyunsaturated fatty acids. Its oxidative stability was found to be equivalent to peanut oil.

Application: lt is used for cooking and frying. as salad oil and mayonnaise. Also, for margarine and shortening production, giving a pleasant flavor.

Flaxseed (linseed) oil: This is obtained from the linseed plant. Flaxseed oil is rich in the unsaturated fatty acid linolenic (50%). The high level of linolenic acids make the oil oxidize quickly, it imparts a paint-like flavor to food products in a very short time therefore edible flaxseed oil is stored under cold, oxygen free, light free conditions and is protected by addition of an antioxidant. lt is sold at many health food stores.

Safflower oil: This is produced from the safflower plant. Safflower produces two types of oil but the common one is an unsaturated oil high in linoleie acid (75-80%). The polyunsaturated fatty acid content is very high hat very low in monounsaturated fatty acids, making it more likely to turn rancid. lt is used for deep frying hat turns toxic when exposed to high heat.

Mustard oil: This is extracted from the seeds of mustard plant (Brassica Campestri L) It has a characteristically pungent flavor and aroma. It contains a high amount of selenium and magnesium. lt has about 70% of monounsaturated fatty acids of which 42% is erucic acid. It is a highly unsaturated oil, high in antioxidants. Mustard oil is considered one of the healthiest edible oils due to its low amount of saturated fatty acids (8%). lt is used for cooking and frying.

Products of edible oil: These include margarines, shortenings, emulsified fats, mayonnaise and salad oils.

Unconventional oils: Unconventional oils such as oils from Mango kernel. Cleome viscoss, Mesta, Terminalia bellirica, neem, rice bran, kapok and Mahua have been investigated for their safely and nutritional quality.

Tomato seed oil: This is produced from tomulue seeds. The seed contnins 25% of oil that is brown or reddish in colour. It is rich in oleic and linuleic acids. The oil is used us salad oil and colour preparation of margarine.

Chilli seed oil: This is obtained from chilli seeds. The seed contains 20-24% oil rich in Linoleie acid. The oil is pungent and can be substituted for spices in food preparation. Refined oil can be used us edible oil.

Water melon seed oil: This is obtained from watermelon seed. The seed yields 28% oil, rich in linoleic acid. It can be used us cooking oil.

Mango kernel fat: This is produced from the kernel of mango. lt is composed of 6-l2% of a solid edible fut. It is cream colored solid at room temperature but melts at 3-l.5ºC and is rich in oleic and stearic acids. It is a substitute for cocoa butter for in the confectionary industry (Table 1).

|

Oil |

World Average Oil Yields 2000/2001 |

Major Producing Countries (in Million Tones) |

|

Palm kernel oil |

44.6% |

Malaysia (1.5), Indonesia (0.77), Nigeria (0.19) |

|

Soybean oil |

18.3% |

US (8.24), Brazil (4.28), Argentina (3.28), China (3.26). |

|

Rapeseed oil (Canola) |

38.6% |

China (4.53), EU (3.68), India (1.60), Canada (1.30). |

|

Sunflower oil |

40.9% |

Former USSR (2.40), EU (2.04), Argentina (0.32), Central Europe (0.70) |

|

Groundnut oil |

40.3% |

China (2.38), India (1.06), Nigeria (0.32), Sudan (0.16) |

|

Cotton seed oil |

15.1% |

China (1.12), India (0.45), US (0.40) |

|

Coconut oil |

62.4% |

Philipines (1.47), Indonesia (0.80), India (0.44) |

|

Sesame oil |

42.4% |

China (0.23), India (0.15), Myanmar (0.09) |

|

Linseed oil |

33.5% |

EU (0.20), China (0.16), US (0.13) |

|

Palm oil |

50% |

Malasysia (11.98), Indonesia (7.33), Nigeria (0.75) |

|

Olive oil |

30% |

Spain (1.01), Greece (0.44), Italy (0.35), Turkey (0.21) |

|

Corn oil |

5% |

US (1.16), EU (0.21), Japan (0.11) |

Table l: Major oil producing countries and the world average oil yields.

Source: Srilakshmi [7].

METHODS OF EXTRACTION

Extraction Process can remove the components of edible oils which may have negative effects on taste, stability, appearance or nutritional value as well preserve tocopherols and prevent chemical changes in the triacylglycerol.

Rural or traditional oil extraction

Storage: In most rural operations, sun-drying reduces the moisture content of oil seeds to below 10 percent. Adequate ventilation or aeration of the seeds or nuts during storage ensures low moisture levels and microbial development is avoided. This is important in the storage of groundnuts which are highly susceptible to aflatoxin contamination through the growth of Aspergillus flavus. Since aflatoxins and pesticides are not removed by rural extraction techniques, microbial contamination and the application of insecticides should be avoided.

Pre-treatment

Sterilization and heat: These treatment by steaming or boiling inactivates lipolytic enzymes which could cause rapid degradation of the oil and facilitates the pulping of the mesocarp for oil extraction. For example, "Sterilised" palm fruits are pulped in a wooden pestle and mortar or mechanized digester.

Decortication or shelling separates the oil-bearing portion of the raw material and eliminates the parts that have little or no nutritional value. Small-scale mechanical sellers are available for kernels and nuts although manual cracking is still prevalent.

Most oil seeds and nuts are heat-treated by roasting to liquify the oil in the plant cells and facilitate its release during extraction. All oil seeds and nuts undergo this treatment except palm fruits for which "sterilization" replaces this operation.

To increase the surface area and maximize oil yield, the oil-bearing part of groundnuts, sunflower, sesame, coconut, palm kernel and shea nuts is reduced in size. Mechanical disc-attrition mills are commonly used in rural operations.

EXTRACTION

Hot water extraction

In oil extraction, milled seed is mixed with hot water and boiled to allow the oil to float and be skimmed off. The milled oil seed is mixed with hot water to make a paste for kneading by hand or machine until the oil separates as an emulsion. In groundnut oil extraction, salt is usually added to coagulate the protein and enhance oil separation.

Mechanical expeller extractors

A large rotating pestle in a fixed mortar system can be powered by motor, humans or animals to apply friction and pressure to the oil seeds to release oil at the base of the mortar. Other traditional systems used in rural oil extraction include the use of heavy stones, wedges, levers and twisted ropes. For pressing, a plate or piston is manually forced into a perforated cylinder containing the milled or pulped oil mass by means of a worm. The oil is collected below the perforated chamber. A variety of mechanical expellers have been designed. The pre-heated raw material is fed into a horizontal cylinder by a worm shaft. By means of an adjustable choke, internal pressure which is built up in the cylinder ruptures the oil cells to release the oil.

Dehydration

By boiling in shallow pans, traces of water in crude oil are removed after settling. This is common in all rural techniques which recognize the catalytic role of water in the development of rancidity and poor organoleptic qualities.

Press-pressed cakes

A by-product of processing, the pressed cake, may be useful depending on the oil extraction technique applied. Cakes from water-extracted oil are usually depleted of nutrients. Other traditional techniques, for instance, those used for groundnut and copra ensure that the by-products, if handled with care, are suitable for human consumption.

Industrial or commercial-scale production

Processing: Oilseeds are generally cleaned of foreign matter before dehulling. The kernels are ground to reduce size and cooked with steam, and the oil is extracted in a screw or hydraulic press. The pressed cake is flaked for later extraction of residual fat with solvents such as "food grade" hexane. Oil can be directly extracted with solvent from products which are low in oil content, that is, soybean, rice bran and corn germ.

After sterilization, oil-bearing fruits are pulped (digested) before mechanical pressing often in a screw press. Palm kernels are removed from pressed cakes and further processed for oil. Animal tissues are reduced in size before rendering by wet or dry processes. After autoclaving, tissues of fish are pressed and the oil/water suspension is passed through centrifuges to separate the oil.

Solvent extraction methods: Newer method of extracting of oil such as multi stage counter current extraction, like battery extraction and multi-stage cross flow extraction-like soxhlet methods are invoked. Other includes.

High pressure solvent extraction methods: Here, high pressure is employed to maintain the solvent in a liquid state at high temperature. The biomass is packed in a cell and kept in an oven and the solvent is then pumped from a reserviour into the cell which is then heated at and pressed at specific time and program. The cell is flushed with nitrogen gas and filtered extract collected in a flask.

Microwave assisted extraction methods: The application of microvae to heating solvent and plant tissues in extraction process is called (MAE). Here the kinetic energy is increased for extraction process with the help of polar additives since hexan or toulen are non polar solvent. The mechanism is due to migration of ions creating rotainal dipoles which changes the molecular structure provided the temperature during extraction is not too high

Supercritical fluid extraction method: The use of supercritical fluid, characterized by critical point defined in terms of critical temperature and critical pressure. It is similar to hydro-distillation. The principle allows supercritical carbondioxide extraction and one stage subcritical separation. It does not allow selective extraction because of the simultenous extraction of many unwanted compounds

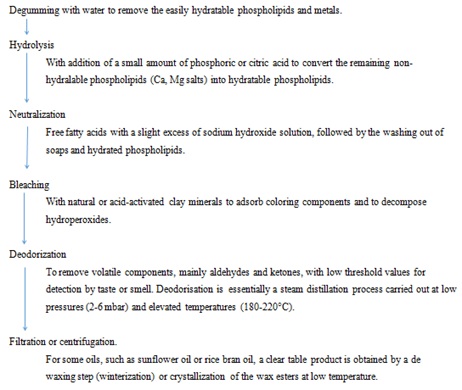

Oil Refining

Refining produces an edible oil with characteristics that consumers desire such as bland flavor and odour, clear appearance, light colour, stability to oxidation and suitability for frying. Two main refining routes are alkaline refining and physical refining (steam stripping, distillative neutralization) which are used for removing the free fatty acids.

Alkaline Refining method

Randomization or interesterification approach of saturated with polyunsaturated fatty acid or triglyceride rearrangement-oil supplementation others include solvent method.

Potential side reactions during oil processing

Cis-trans isomerisation: One of the most sensitive parameters used to detect chemical changes resulting from severe processing conditions is cis-trans isomerisation, especially of linolenic acid. The most complete study in this area was made, who investigated the formation of geometric isomers in various oils on the laboratory, pilot plant and production scales.

Trans fatty acid formation: The formation of positional isomers (that is, double bonds shifted along the fatty acid chain) of linolenic and linoleic acid under deodorisation/physical refining conditions has not been reported.

Physical losses: During deodorisation or physical refining, volatile components are removed from the oil by the combination of high temperature, low pressure and stripping action of inert gas (steam).

FAT AND OIL CONSTITUENTS

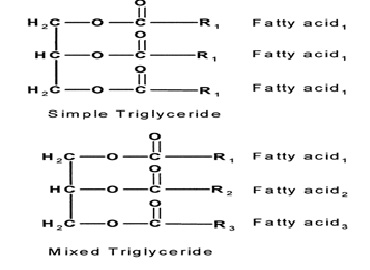

Triglycerides

A triglyceride consists of three fatty acids attached to one glycerol molecule. If all three fatty acids are identical, it is a simple triglyceride. Chemical compounds found in the fat before it was split are known to chemists as triglyceride. Since there are a number of different fatty acids that occur in natural fats, a great many different triglyceride are encountered in nature. These are named according to the fatty acid or acids they contain. Thus triolein is the triglycerid of oleic acid, tripalmitin that of palmitic acid, tristearin that of stearic acid, while monopalmitin-distearin contains, as the name indicates, one molecule of palmitic and two of stearic acid. While a large variety of fatty acids is found in natural fats and oils, only a few of them are of outstanding commercial importance. These are myristic acid, lauric acid, palmitic acid, stearic acid, oleic acid, linolic acid, and linolenicacid. Though the number of triglyceride encountered in nature is great, the triglyceride of these seven acids (see table of formulas below) make up the great bulk of the natural fats and oils. Fats and oils are practically always mixtures of triglyceride in varying proportions. In some fats one triglyceride predominates, in others another, and in still others several are present in material amounts. Apparently no natural fat or oil consists solely of a single triglyceride. The properties of different fats and oils depend upon the characteristics of the triglyceride of which they are mixtures and upon the proportions of this triglyceride to one another. (See fatty acids table below.

Diagrams triglycerides structure

O'Brien [8], the fatty acids in a triglyceride define the properties and characteristics of the molecule.

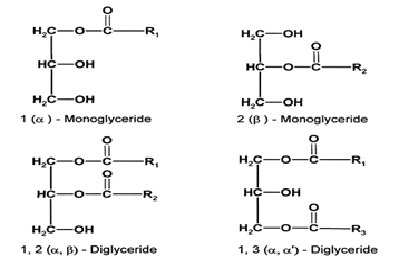

Mono-and Diglycerides

Mono- and diglycerides are mono- and diesters of fatty acids and glycerol. They are prepared commercially by the reaction of glycerol and triglycerides or by the esterification of glycerol and fatty acids. Mono- and diglycerides are formed in the intestinal tract as a result of the normal digestion of triglycerides. They occur naturally in very minor amounts in both animal fats and vegetable oils. Oil composed mainly of diglycerides has also been used as a replacement for oil composed of triglycerides. Illustrations of mono- and triglyceride molecular structures are provided below.

Diagrams of mono-and diglycerides

O'Brien [8], free fatty acids As the name suggests, free fatty acids are the unattached fatty acids present in a fat. Some unrefined oils may contain as much as several percent free fatty acids. The levels of free fatty acids are reduced in the refining process. Fully refined fats and oils usually have a free fatty acid content of less than 0.1%.

SATURATED AND UNSATURATED FATTY ACIDS

Saturated fats

When the fatty-acid molecule contains the maximum of hydrogen possible, the acid is said to be a saturated fatty acid. It is saturated with respect to hydrogen. Myristic, lauric, palmitic, and stearic acids are such saturated acids. They are solids at ordinary temperatures [9-11].

Certain fatty acids are already 'naturally saturated' in that they cannot be made 'harder' than they are in nature. As previously noted, the levels of saturates is generally higher in those fats which are solid at ambient temperatures. Saturated fatty acids are extremely stable i.e. they do not easily become rancid, meaning they have good keeping properties (shelf life). However, Government recommendations advise consumers to limit their intake of saturated fats as they can increase blood cholesterol levels, one of the major factors in heart disease. Most animal fats such as meat, butter, cheese and cream contain relatively high levels of saturated fat and as such should be eaten in moderation. Many baked goods such as cakes, biscuits and pastries can also be high in saturated fat.

Unsaturated fatty acid

When, however, the fatty-acid molecule does not contain the maximum amount of hydrogen possible, the acid is said to be an unsaturated fatty acid. It is unsaturated with respect to hydrogen. Such unsaturated acids are oleic, linolic, and linolenic acids. They are liquids at ordinary temperature.

There are three types of unsaturated fatty acids

Monounsaturated Fatty Acids (MUFA) fatty acids in this category have what is known as one double bond in their chemical make-up. They are relatively stable to oxidation and the development of rancidity and are now considered, in nutritional terms, as being the best type of fat to eat. The most common source of monounsaturated Olive Oil and Rapeseed oils.

Polyunsaturated Fatty Acids (PUFA) polyunsaturated fatty acids contain two or more double bonds in their chemical make-up. They are least stable fatty acids to oxidation and as such are best used in cold applications. The most common source of polyunsaturates is Sunflower seed oil.

Trans Fatty Acids (TFA) trans fatty acids typically come from two sources, hydrogenated vegetable oils and animal fats. Recent scientific research suggests trans fats, although consumed in relatively small proportions, should be avoided due to their negative effect on blood cholesterol levels.

Phosphatides: Phosphatides, also known as phospholipids, consist of an alcohol (usually glycerol) combined with fatty acids, and a phosphate ester. The majority of the phosphatides are removed from oil during the degumming and refining operations. Phosphatides are an important source of natural emulsifiers marketed as lecithin.

Sterols: Sterols are found in both animal fats and vegetable oils, but there are substantial biological differences. Cholesterol is the primary animal fat sterol and is found in vegetable oils in only trace amounts. Vegetable oil sterols and plant sterols are collectively called "phytosterols." Stigmasterol and sitosterol are the best-known vegetable oil sterols. Sitosterol has been shown to reduce both serum and LDL cholesterol when incorporated into margarines, margarine spreads, salad dressings and various other food products to provide a convenient mode of delivery for consumers who choose to leverage phytosterols as a component of their personal plan to manage serum cholesterol levels. The type and amount of vegetable oil sterols vary with the source of the oil.

Tocopherols and tocotrienols: Tocopherols and tocotrienols are important minor constituents of most vegetable fats. They serve as antioxidants to retard rancidity and as sources of the essential nutrient vitamin E. The common types of tocopherols and tocotrienols are alpha (α), beta (β), gamma (γ), and delta (δ). They vary in antioxidation and vitamin E activity. Among tocopherols, alpha-tocopherol has the highest vitamin E activity and the lowest antioxidant activity. Delta tocopherol has the highest antioxidant activity. Tocopherols which occur naturally in most vegetable oils are partially removed during processing. Corn and soybean oils contain the highest levels. Tocopherols are not present in appreciable amounts in animal fats. Tocotrienols are mainly present in palm oil, but can also be found in rice bran and wheat germ oils.

Pigments: Carotenoids are yellow to deep red color materials that occur naturally in fats and oils. They consist mainly of carotenes such as lycopene, and xanthophylls such as lutein. Palm oil contains the highest concentration of carotene. Chlorophyll is the green coloring matter of plants which plays an essential role in photosynthesis. Canola oil contains the highest levels of chlorophyll among common vegetable oils. At times, the naturally occurring level of chlorophyll in oils may cause the oils to have a green tinge. Gossypol is a pigment found only in cottonseed oil. The levels of most of these color bodies are reduced during the normal processing of oils to give them acceptable color, flavor, and stability.

Fatty alcohols. Long chain alcohols are of little importance in most edible fats. A small amount esterified with fatty acids is present in waxes found in some vegetable oils. Larger quantities are found in some marine oils (Table 2).

|

Fat or Oil |

Phosphatides (%) |

Sterols (ppm) |

Cholesterol (ppm) |

Tocopherols (ppm) |

Tocotrienols (ppm) |

|

Soybean |

2.2±1.0 |

2965±1125 |

26±7 |

1293±300 |

86±86 |

|

Corn |

1.25±0.25 |

15,050±7100 |

57±38 |

1477±183 |

355±355 |

|

Cottonseed |

0.8±0.1 |

4560 ± 1870 |

68±40 |

865±35 |

30±30 |

|

Peanut |

0.35±0.05 |

1878±978 |

54±54 |

482±345 |

256±216 |

|

Olive |

<0.1 |

100 |

<0.5 |

110 ± 40 |

89±89 |

|

Palm |

0.075±0.025 |

2250±250 |

16±3 |

240±60 |

560±140 |

|

Coconut |

<0.07 |

805±335 |

15±9 |

6±3 |

49±22 |

|

Palm Kernel |

<0.07 |

1100±310 |

25±15 |

3± |

30±30 |

Table 2: Typical non-triglyceride components of crude fats and oils [8].

CONCLUSION

Traditional refining of oil-bearing plants can produce fats and oils of good quality which provide needed energy and fat soluble vitamins. Commercial refining produces fats and oils that can be of high quality and have the characteristics of bland taste, clear colour, good keeping quality and frying stability. Refining may remove nutritionally valuable carotenoids to yield oils of low colour, but retains substantial proportions of tocopherols, and does not change fatty acid nor triacylglycerol compositions. Temperature, time and pressure must be carefully controlled during industrial refining.

REFERENCES

- Potter NN, Hotchkiss JH (2012) Food Science: Fifth Edition. Springer Science & Business Media, Berlin, Germany.

- Johnson S, Saikia N (2009) Fatty acids profile of edible oils and fats in India. Centre for Science and Environment. New Delhi, India.

- Aloyor EO, Ozigagu CE, Oboh OI, Aluyor P (2009) Chromatographic analysis of vegetable oils: A review. Scientific Research and Essay 4: 191-197.

- Mishra S, Manchanla SC (2012) Cooking oils for heart health. Journal of Preventive Cardiology 1: 123-131.

- Gunstone FD (2002) Vegetable oils in food technology: Composition, properties and uses. Blackwell Publishing, New Jersey, USA.

- Lawson HW (2013) Food oils and fats: Technology, utilization and nutrition. Springer Science & Business Media, Berlin, Germany.

- Srilakshmi B (2003) Food Science. New Age International Publishers. Hyderabad, India.

- O'Brien RD (2008) Fats and Oils: Formulating and processing for applications, Third Edition. CRC Press, Florida, USA.

- Ihekoronye AI, Ngoddy PO (1985) Integrated food science and technology for the tropics. MacMillan Education Ltd, London. UK.

- Samarth NB, Mahanwar PA (2015) Modified Vegetable oil based additives as a future polymeric material-A Review. Open Journal of Organinc Polymer Material 5: 1-22.

- Strayer D (2006) Food Fats and Oil. (9th Edn). Institute of Shortening and Edible Oils, Washington, D.C. USA.

Citation: Ogori AF (2020) Source, Extraction and Constituents of Fats and Oils. J Food Sci Nutr 6: 060.

Copyright: © 2020 Ogori AF, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.